Just an update on the engine build.

Put the crankshaft plus new bearings in the engine case....

I installed the Enkle 100 cam shaft.....

put the case back together and all was good.

Put the new oil pump in and all was NOT good....

Engine would not turn....

The cam shaft was hitting on the back of the oil pump.

Split the engine case again....ground some off the rear of the oil pump housing and off the top of the camshaft bolts.

That did the trick....

Engine case now back together and spinning.

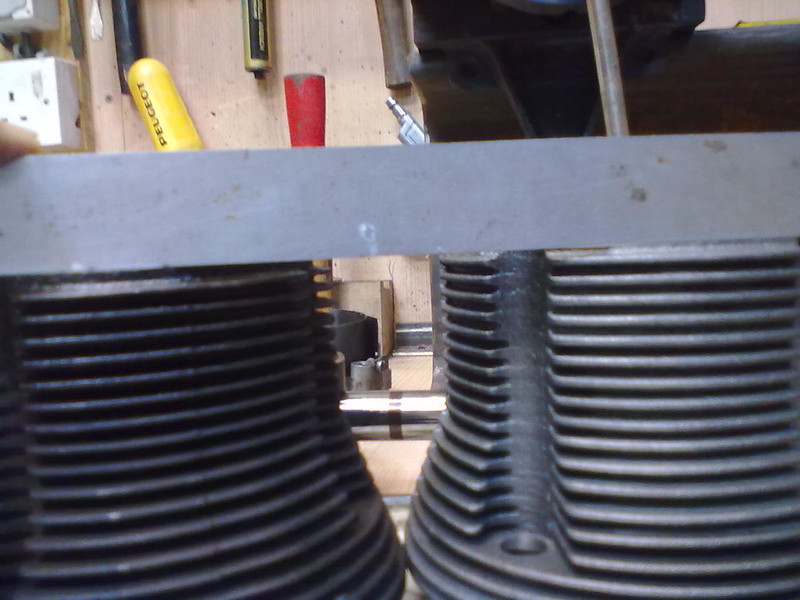

Have just put the bigger 1776cc pots on and checked the compression ratio.

I used a handy ratio calculator app...

http://www.csgnetwork.com/compcalc.html" onclick="window.open(this.href);return false;

Bore Size : 90.5 mm

stroke length : 69mm

Headgasket bore : 0 (no gasket)

Headgasket thickness : 0 (no gasket)

Combustion chamber volume : 59 CC's

piston Dome : 0 (as Flat Piston Head)

Piston Deck Clearance : 1.43 mm (measured with piston at TDC)

Got a compression Ratio of 7.508 : 1.

Aircooled .Net state "Enkle 100 Cam compression Ratio range is 7.5 to 8.25 : 1"

so all seems good to go ahead and put the cylnder heads on.

Will have to work out the piston rod lengths once the head goes on.

Will put some pictures up in a moment but need to get them off my phone first.

Cheers.