Distributor drive gear not engaging

Moderators: User administrators, Moderators

- handsmann

- Registered user

- Posts: 79

- Joined: 23 Jul 2014, 06:36

- 80-90 Mem No: 13724

- Location: Manchester M23

Distributor drive gear not engaging

We have a 1985 van with a 1.9 WBX (DG) that I have been unable to get running for over three weeks now. Our mechanic took a look at it a week ago, took the dizzy out, looked at the worn drive gear and recommended I buy a new one.

I fitted a brand new SSP vacuum distributor with Hall sender at the weekend and could not get the engine to run for more than 10 seconds or so without a very bad backfire. This evening I very carefully cranked the engine over by hand through 3 complete cycles and the rotor ends up pointing roughly to the point where the spring clip closest to the front of the van would be.

I've tried to attach a photo but failed.

This when the #1 piston is at TDC on its compression stroke. I've triple-checked this now.

The problem I'm still having is that I can still rotate the distributor shaft with my fingers without applying excessive force. If feels like the driver gear/dog at the base of the distributor shaft will 'skid' even though the distributor is as firmly located as it can be. My question is threefold:

a) Can an aftermarket (SSP) distributor have a shaft so inaccurately machined that the gear won't engage?

b) Can the gear which drives the distributor from the camshaft be worn enough to cause this 'skidding'?

c) Is it possible to buy a distributor clamp/bracket of lighter gauge steel to allow the distributor to sit 1mm or so lower in the engine? The existing clamp is quite sturdy and the steel is about 2mm thick.

I'm desperate to be honest. Getting the van through its MOT was a complete nightmare and we have not used it yet this year except for one Saturday outing. Any advice that you can offer will, believe me, be gratefully received.

I fitted a brand new SSP vacuum distributor with Hall sender at the weekend and could not get the engine to run for more than 10 seconds or so without a very bad backfire. This evening I very carefully cranked the engine over by hand through 3 complete cycles and the rotor ends up pointing roughly to the point where the spring clip closest to the front of the van would be.

I've tried to attach a photo but failed.

This when the #1 piston is at TDC on its compression stroke. I've triple-checked this now.

The problem I'm still having is that I can still rotate the distributor shaft with my fingers without applying excessive force. If feels like the driver gear/dog at the base of the distributor shaft will 'skid' even though the distributor is as firmly located as it can be. My question is threefold:

a) Can an aftermarket (SSP) distributor have a shaft so inaccurately machined that the gear won't engage?

b) Can the gear which drives the distributor from the camshaft be worn enough to cause this 'skidding'?

c) Is it possible to buy a distributor clamp/bracket of lighter gauge steel to allow the distributor to sit 1mm or so lower in the engine? The existing clamp is quite sturdy and the steel is about 2mm thick.

I'm desperate to be honest. Getting the van through its MOT was a complete nightmare and we have not used it yet this year except for one Saturday outing. Any advice that you can offer will, believe me, be gratefully received.

1985 RHD 1.9 DG, Pierburg 2E carburettor, high-top, no mods, wannabe mechanic

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Distributor drive gear not engaging

A new dizzy seal is very, very hard to push home so perhaps you just havent got if down far enough, I suggest pull the dizzy, remove seal and check if it sits home correctly.

if so refit seal and push hard on dizzy cap while rotating dizzy, clamp needs to be loose to do this as the stud in the engine will catch otherwise.

Do you have a photo bucket account? If so pit your pic there and post a link.

if so refit seal and push hard on dizzy cap while rotating dizzy, clamp needs to be loose to do this as the stud in the engine will catch otherwise.

Do you have a photo bucket account? If so pit your pic there and post a link.

Last edited by itchyfeet on 28 Jul 2015, 20:17, edited 1 time in total.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Distributor drive gear not engaging

https://club8090.co.uk/wiki/images/Ignit ... _flat4.jpg" onclick="window.open(this.href);return false;

This is the correct dizzy position but the drive shaft cog could have been put in at almost any angle ( 180 degrees being the most common mistake) so don't go by this picture or Haynes, look at the drive cog in engine slot is offset, so is dizzy so align when pushing it in no matter where the rotor arm ends up.

Once in get to TDC on compression then connect No1 lead to whatever position is next to rotor arm contact, then count around.

This is the correct dizzy position but the drive shaft cog could have been put in at almost any angle ( 180 degrees being the most common mistake) so don't go by this picture or Haynes, look at the drive cog in engine slot is offset, so is dizzy so align when pushing it in no matter where the rotor arm ends up.

Once in get to TDC on compression then connect No1 lead to whatever position is next to rotor arm contact, then count around.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- handsmann

- Registered user

- Posts: 79

- Joined: 23 Jul 2014, 06:36

- 80-90 Mem No: 13724

- Location: Manchester M23

Re: Distributor drive gear not engaging

itchyfeet wrote:A new dizzy seal is very, very hard to push home so perhaps you just havent got if down far enough, I suggest pull the dizzy, remove seal and check if it sits home correctly.

if so refit seal and push hard on dizzy cap while rotating dizzy, clamp needs to be loose to do this as the stud in the engine will catch otherwise.

Do you have a photo bucket account? If so pit your pic there and post a link.

http://i32.photobucket.com/albums/d38/p ... n0onhj.jpg" onclick="window.open(this.href);return false;

Thank you itchyfeet - I take the point about the dizzy seal. I used fresh engine oil on the shaft and the seal and still had to gently tap the dizzy home with a small wooden block and rubber mallet. Until then I'd literally been bouncing the van on it's springs trying to get the little devil in. Things I've read in the last couple of days have made me realise that a dizzy being 180 degrees out is by no means a rare thing and I'm prepared to relocate the ignition leads to accommodate that. I'm not sure that my photo will be much use even if you can see it - I've left the crankshaft pulley at TDC but currently I could have the dizzy shaft pointing wherever I want...

Thanks a lot for taking the time - again.

Chris

1985 RHD 1.9 DG, Pierburg 2E carburettor, high-top, no mods, wannabe mechanic

- bigherb

- Registered user

- Posts: 2582

- Joined: 27 Mar 2008, 13:50

- 80-90 Mem No: 5789

- Location: West Kent

Re: Distributor drive gear not engaging

Do you mean the drive gear in the engine? If you replaced it or took it out did you refit the shims at the base of the drive gear?

1982 Camper 1970 1500 Beetle Various Skoda's, Ariel Arrow

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Distributor drive gear not engaging

bigherb wrote:Do you mean the drive gear in the engine? If you replaced it or took it out did you refit the shims at the base of the drive gear?

That was my first thought but when I read it again it sounded like the drive on the end of the dizzy.

But a good point if somebody left a thrust washer off the dizzy would not engage fully but I'd think enough, more worrying would be no thrust washers wears the engine case.

In my experience if you pull the drive gear/cog out of the engine the two thrust washers stay behind.

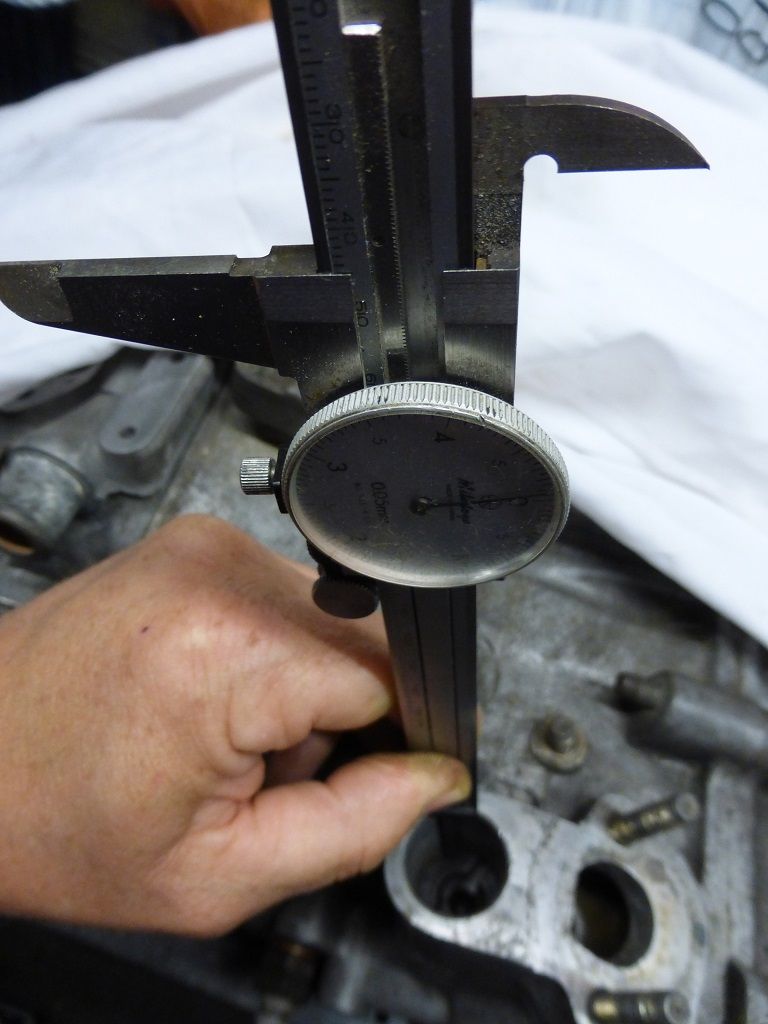

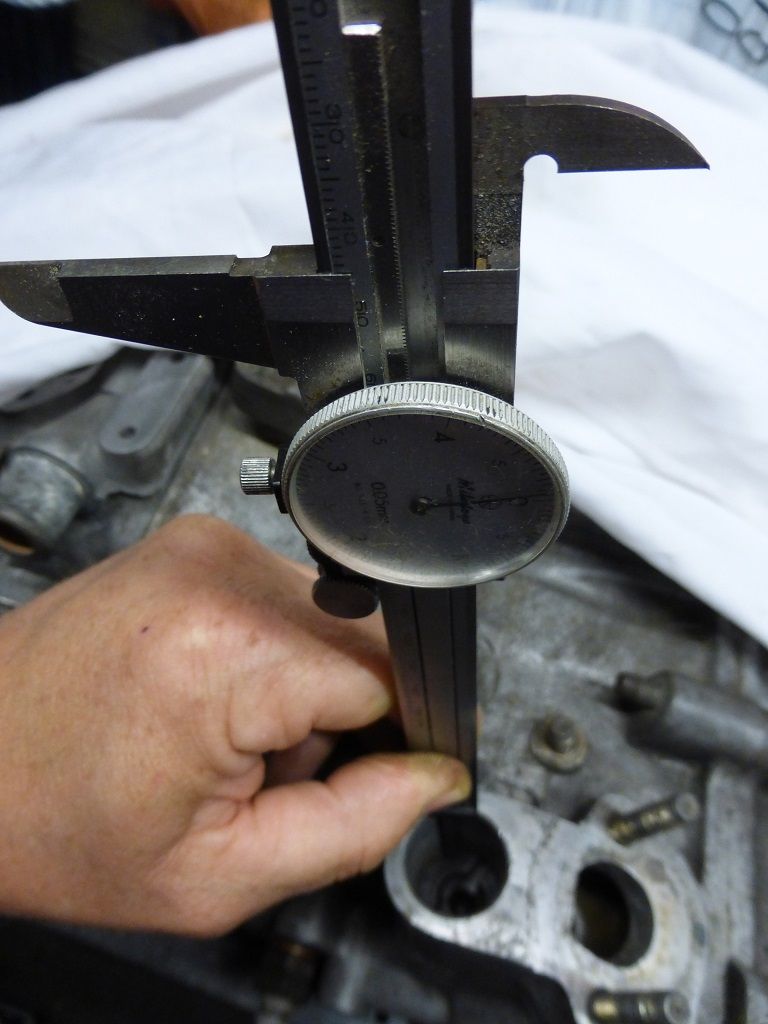

measure how far down drive cog is from engine case, should be 45mm

thrust washers are 0.5mm thick each

when dizzy in there should still be a small gap between engine case and shoulder

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- handsmann

- Registered user

- Posts: 79

- Joined: 23 Jul 2014, 06:36

- 80-90 Mem No: 13724

- Location: Manchester M23

Re: Distributor drive gear not engaging

bigherb wrote:Do you mean the drive gear in the engine? If you replaced it or took it out did you refit the shims at the base of the drive gear?

Yes, sorry, the drive gear in the engine. I haven't replaced it - but I suspect someone in the past has. I'm scratching my head trying to work out how we have driven the few hundred miles we have with the old distributor in place.

You've got me worried now - I didn't know there were (or could be) shims at the base of that drive gear.

Thanks for throwing some light on this...

1985 RHD 1.9 DG, Pierburg 2E carburettor, high-top, no mods, wannabe mechanic

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Distributor drive gear not engaging

As I say measure how deep it sits and get a picture up of it showing any damage.

You can't remove it without removing the fuel pump and rod/spacer, it's hard to get out also.

when posting pictures from photobucket look for the [IMG] link, paste that in your post picture appears

You can't remove it without removing the fuel pump and rod/spacer, it's hard to get out also.

when posting pictures from photobucket look for the [IMG] link, paste that in your post picture appears

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- handsmann

- Registered user

- Posts: 79

- Joined: 23 Jul 2014, 06:36

- 80-90 Mem No: 13724

- Location: Manchester M23

Re: Distributor drive gear not engaging

itchyfeet wrote:

But a good point if somebody left a thrust washer off the dizzy would not engage fully but I'd think enough, more worrying would be no thrust washers wears the engine case.

In my experience if you pull the drive gear/cog out of the engine the two thrust washers stay behind.

measure how far down drive cog is from engine case, should be 45mm

thrust washers are 0.5mm thick each

when dizzy in there should still be a small gap between engine case and shoulder

Yes, guys, you have both understood perfectly what I'm saying. And these photos make everything crystal clear. I'm now very nervous that the shims you mention are missing. The wear issue concerns me a lot - and I would never have worked that out for myself in a million years. I'm going to try everything you have suggested in your posts, including doing some measurements and then if new shims have to be fitted, it will be a professional job. I have neither the tools nor the talent to sort that one out.

After a year of van ownership, it seems that the gradient of the learning curve is not flattening out.

Thank you!

1985 RHD 1.9 DG, Pierburg 2E carburettor, high-top, no mods, wannabe mechanic

- Aidan

- Trader

- Posts: 7200

- Joined: 11 Oct 2005, 19:21

- 80-90 Mem No: 742

- Location: Llanfyllin, mid Wales : )

Re: Distributor drive gear not engaging

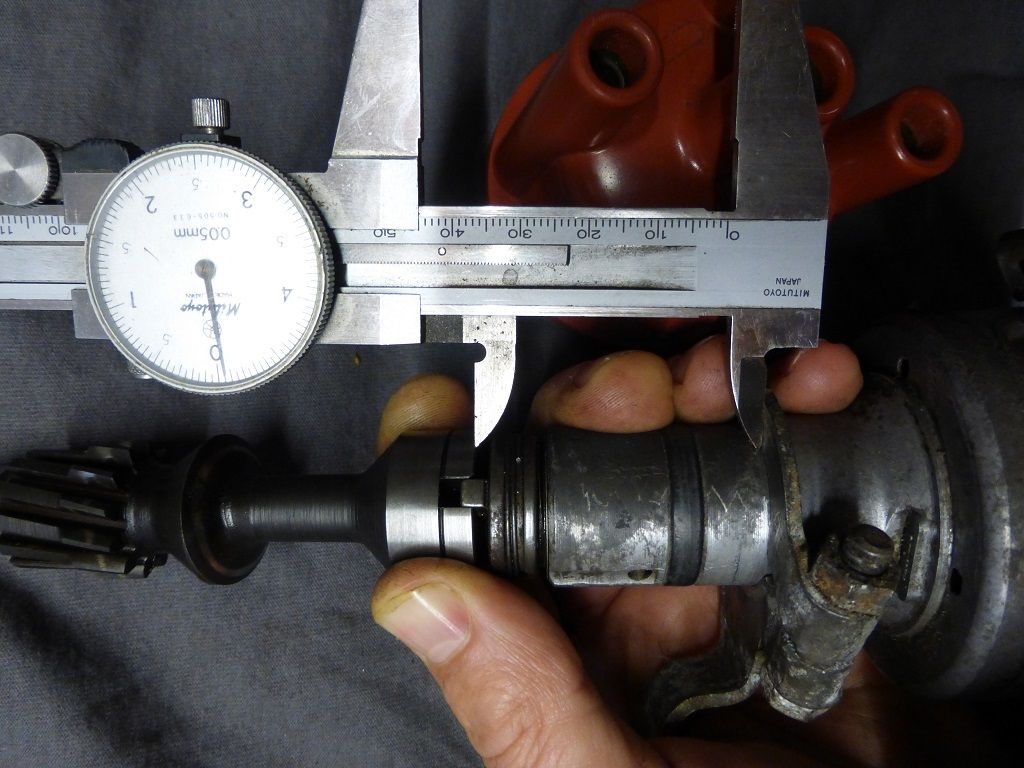

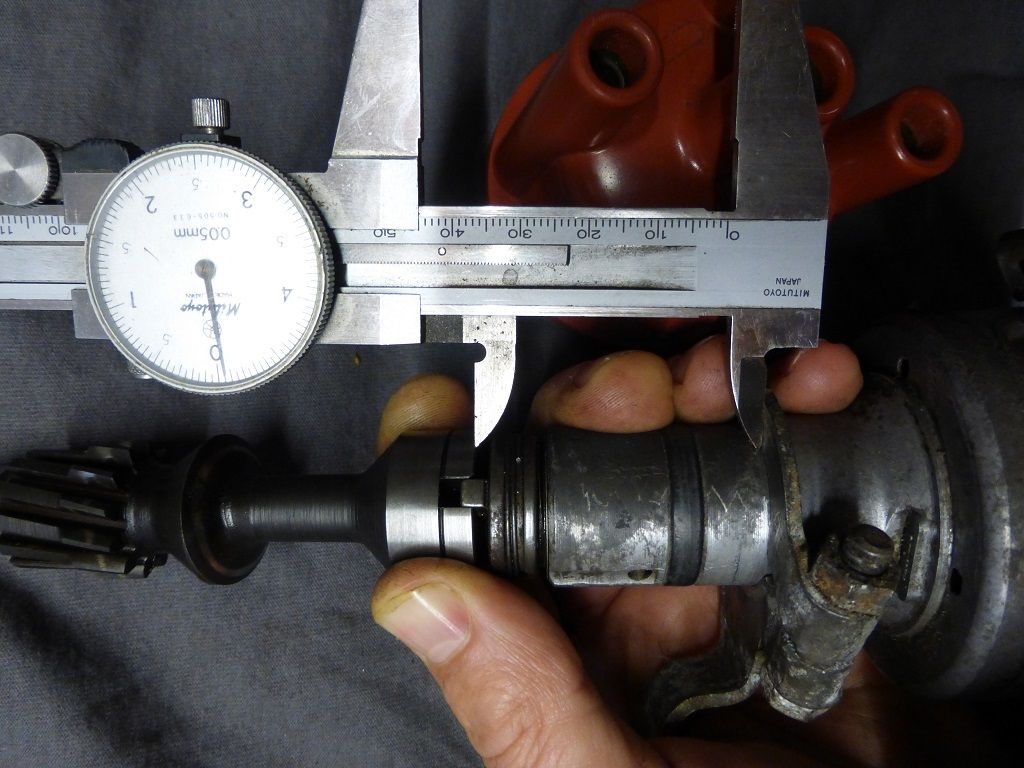

whilst measuring things perhaps check the length of the shaft etc of the disi as it's non genuine, just in case.......

AIDAN

- handsmann

- Registered user

- Posts: 79

- Joined: 23 Jul 2014, 06:36

- 80-90 Mem No: 13724

- Location: Manchester M23

Re: Distributor drive gear not engaging

Aidan wrote:whilst measuring things perhaps check the length of the shaft etc of the disi as it's non genuine, just in case.......

Yes, definitely. I still have the old dizzy to compare with, though the wear pattern on the drive gear of that one suggests that some slippage has been going on for a while. The old dizzy looks filthy enough to be original, but who knows?

Cheers.

Chris

1985 RHD 1.9 DG, Pierburg 2E carburettor, high-top, no mods, wannabe mechanic

- handsmann

- Registered user

- Posts: 79

- Joined: 23 Jul 2014, 06:36

- 80-90 Mem No: 13724

- Location: Manchester M23

Re: Distributor drive gear not engaging

itchyfeet wrote: when dizzy in there should still be a small gap between engine case and shoulder

Itchyfeet, I know just what I need to do now, but haven't got time to do it this evening sadly. Looking at this last photo, I can see how the shoulder should sit, but I can't see a clamp on it.

How can you get the distributor clamp to fit round the shoulder rather than just below it? My new dizzy sits with the clamp around the top of the shaft and so below the shoulder - I just looked at the old dizzy and it's exactly the same. I struggled to get the clamp over the oil seal on the new dizzy - I don't think there is any way I could get it wide enough to clamp around the shoulder.

Maybe there are clamps which give a greater range of movement. I realise that the crucial 45mm drop from the engine casing opening to the drive gear still has to be checked regardless because I need to know if the shim(s) are in place. By the way, I saw this today https://www.vwheritage.com/shop/AC00011 ... -tighten/#. Too good to be true I imagine, but interesting...

Sorry, getting excited about tools and trying to sound like a mechanic, when I'm not

Thanks

Chris

1985 RHD 1.9 DG, Pierburg 2E carburettor, high-top, no mods, wannabe mechanic

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Distributor drive gear not engaging

Yes sorry that picture was a bad test not well explained but does enable you to check depth without a proper measuring device ( vernier calipers are not expensive)

When the dizzy is pushed hard down onto drive cog you should still be able to see a gap ( where the clamp plate goes), it won't be as thick as the clamp plate because there must be some clearance between the drive cog and dizzy shaft when clamp plate fitted, no gap means you probably have more than 45mm.

Anyway forget that, measure the 45mm depth, as you can see for the second picture 45mm means the dizzy shaft has plenty of engagement into the drive cog with clamp plate fitted. If the cog is 46mm down then thrust washers probably missing and as you an see there will be barely any engagement.

Note there is a spring between drive cog and dizzy shaft, this is very important to stop the drive cog lifting.

inside view showing thrush washers which stop the hard steel cog wearing the soft aluminium case.

When the dizzy is pushed hard down onto drive cog you should still be able to see a gap ( where the clamp plate goes), it won't be as thick as the clamp plate because there must be some clearance between the drive cog and dizzy shaft when clamp plate fitted, no gap means you probably have more than 45mm.

Anyway forget that, measure the 45mm depth, as you can see for the second picture 45mm means the dizzy shaft has plenty of engagement into the drive cog with clamp plate fitted. If the cog is 46mm down then thrust washers probably missing and as you an see there will be barely any engagement.

Note there is a spring between drive cog and dizzy shaft, this is very important to stop the drive cog lifting.

inside view showing thrush washers which stop the hard steel cog wearing the soft aluminium case.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- handsmann

- Registered user

- Posts: 79

- Joined: 23 Jul 2014, 06:36

- 80-90 Mem No: 13724

- Location: Manchester M23

Re: Distributor drive gear not engaging

itchyfeet wrote: Anyway forget that, measure the 45mm depth, as you can see for the second picture 45mm means the dizzy shaft has plenty of engagement into the drive cog with clamp plate fitted. If the cog is 46mm down then thrust washers probably missing and as you an see there will be barely any engagement.

I must be more tired than I thought - I had to read all of this three times before I got it - now I've got it and I can't thank you enough for the explanation and spot-on photos. I want to get this sorted in time to take the van to NWVW at Tatton on August 2nd. I think I'm in for a sleepless night thinking about the engine casing wearing out...

Thanks again!

Chris

1985 RHD 1.9 DG, Pierburg 2E carburettor, high-top, no mods, wannabe mechanic

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Distributor drive gear not engaging

It's only an engine, if the washers are missing it's only just started to slip so adding two (or three washers if there is some wear) will fix it.

sleep well

sleep well

1988 DG WBX LPG Tin Top

itchylinks

itchylinks