Here is the van when we had just bought it, with the original black roof cap. What you can't see is how badly it sags on top!

We removed the roof with the help of a couple of friends.

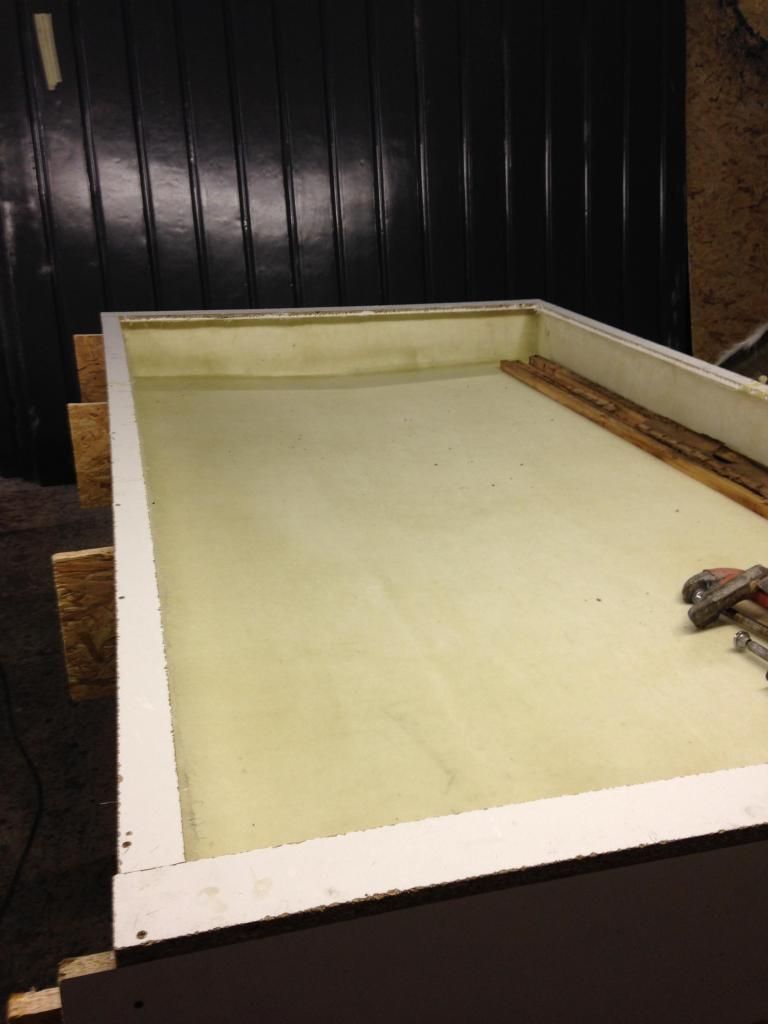

I found a company locally (Cornwall) to make a fibreglass roof cap exactly like the existing one - Shapes GRP in Bissoe, Cornwall. He took the old roof cap, made a mould and made a new fibreglass roof cap to the same dimensions.

We were charged £660 for this, as there was a lot of labour and time involved in making the mould in addition to the roof cap. I'm sure it would cost less for them to make a second one. It was all a bit trial and error. We needed wooden batten fixed in so that we could attach the hinges for the folding sides, and the gas struts, so he fibreglassed 10cm of 12mm plywood in around each edge.

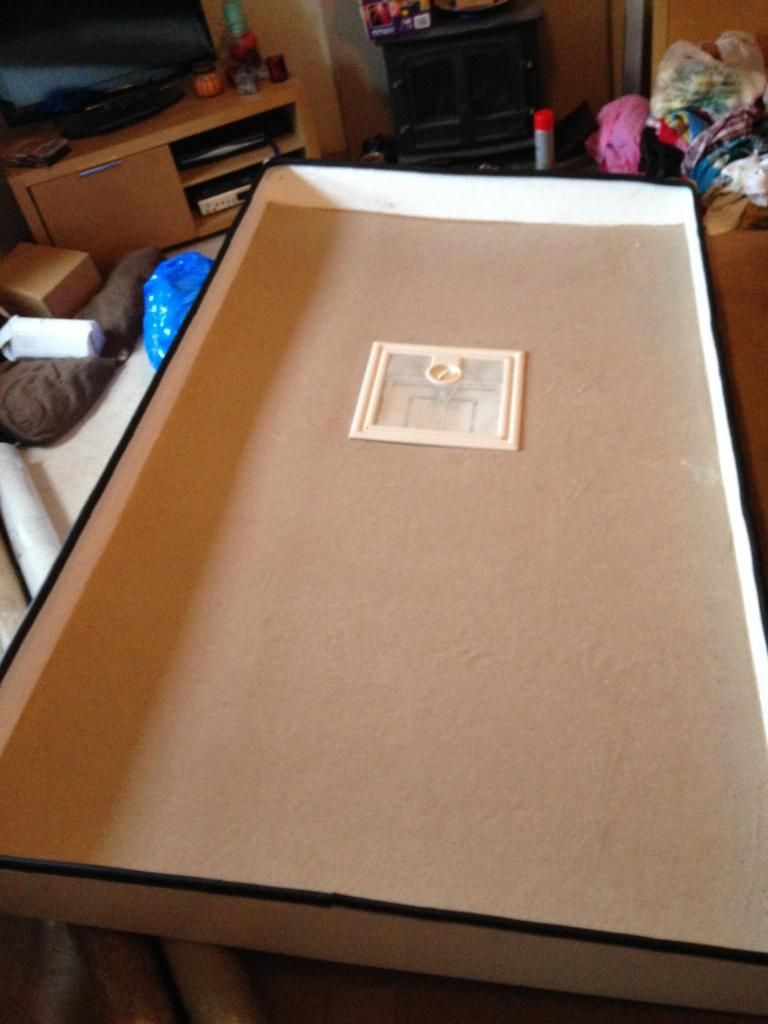

Once we had the roof cap home, I had the arduous task of fitting out the interior with insulation, boarding it with 4mm plywood and carpeting it.

Then the folding sides needed to be attached in the correct places, and curved wooden ends made for the folding front and back to attach to.

It sounds easy, but this took me hours and hours. It was made more difficult because our original roof had pretty much fallen apart, or been taken apart at the workshop when he was measuring it to make the mould, so we had nothing to take accurate measurements from. It was very difficult measuring from what we had (the bottom part of the pop top) and transposing that to the roof cap when we didn't know excactly how they would line up.

I stupidly forgot to take a photo of it completely fitted out before we put the roof back on - I ran out of time. We had acro props on hire, four friends waiting to help (in addition to my son and husband), and the weather wasn't going to stay dry for long! As soon as I got the last screw in we got it up on the van to attach the gas struts.

Here the gas struts are fixed, the roof is secured by two locks, and my daughter and I slept in it for the first time (in the driveway) to try it out. No leaks!

It was another few weeks before we managed to get all the folding ends attached properly due to the weather - as soon as we'd pop the roof up and start working on it the heavens would open! The first time we attached both ends, the sides didn't line up right to we had to make a few minor changes, but finally got it all sorted.

Here is a link to the slideshow on photobucket, with more photos. I tried to take one of everything I did along the way. http://s1216.photobucket.com/user/tinas ... eplacement

The only issue we had during this process was the fact that we didn't have the original roof to measure the interior fitting from - and the exact position of the gas strut brackets. If we had had this it would have been far easier. I might have also tried to glue the wooden battens rather than fibreglass them in because to screw through the fibreglass into the wooden batten I had to countersink each hole, otherwise the gel coat would crack, the fibreglass broke up and made a mountain and the screw wouldn't go in. This meant I had to know the position of every single screw and then countersink or pre drill the holes before boarding and carpeting, and then mark them accurately on the carpet. Very labour intensive, and no room for error.

It was all a bit of trial and error really, but i am happy with how it goes together now. it's not perfect - there are a couple of small gaps where the sides and end don't meet exactly - but I can work out a fix for this. I've got a couple of seals missing on the folding sides, but I will source these from eBay.

If anyone else is considering doing something similar I would be happy to give you more details about any part of the process. It was a bit of a mission but it's been well worth it!

I have since re-wallpapered the interior and fixed a new light inside. I will post more photos once I get the mattress covered and get it looking nice.