But I don't think I'll be doing another iteration, because after a few tests this evening I think I'm there.

I started off with R4 set to 191 Ohms using a 1K variable, and R8 set to 802, using another 1K variable. As soon as I connected the power, without the engine running, the needle swung right over to the right. So I changed R8 to 10K, and that solved that problem. Then I started the engine, and I was able to get it spot on by adjusting RV1. Then I removed R8 altogether, and nothing changed. So evidently I can do without R8. Maybe it should be a capacitor after all - I may try that.

So then I adjusted R4 and I found that almost anything I did to that resistor could be compensated by RV1. So evidently 191 isn't a critical value. I put my original 200 Ohm fixed resistor back in there and then tweaked RV1 until it was spot-on again.

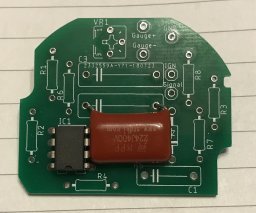

I reckon that might be it. I can use my existing PCB without modification, simply by leaving out R8, which a) should be between pins 1 and 4, not pins 2 and 4, b) may be 10k rather than 802, and c) might actually be a capacitor. Apart from that there's nothing wrong with it!

*E D I T - message crossed with Bob's