Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Moderators: User administrators, Moderators

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Thank you. I wondered whether dropping them as a unit would save some tricky steps, like removing the starter, undoing the mating bolts in-situ, then aligning the input shaft with the clutch when refitting etc. But on balance I think you're right, mainly because of the weights involved. The gearbox I know I can just about lift on my own, but yes, manoeuvring the engine is a problem. I'm hoping to make or borrow a trolley on castors, and I do have someone who can help me lift one engine off it and the other one on. Failing a trolley, I have two trolley jacks so could put one under each side of the engine to give me 'wheels'. Point taken about access to bolts while it's in the van. Planning to strip everything off the engine before dropping it to minimise the risk of damage, especially the exhaust.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

ash1293 wrote:Could try and find an old pallet dolly knocking round somewhere - could drop the whole lot onto the frame and then wheel out.

Not sure I could find one ready made, but that's reminded me that I do have a pallet, and a set of castors, so I should be able to make one easily enough.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

removing starter is easy

I saw somebody recently with an engine on a skateboard, you don't need wheels, a sheet of wood with some rope tied to the wood and you can drag it, a trolley with wheels is easier with flat ground but the sheet of wood is easier with rough ground unless you have large wheels on trolley

I saw somebody recently with an engine on a skateboard, you don't need wheels, a sheet of wood with some rope tied to the wood and you can drag it, a trolley with wheels is easier with flat ground but the sheet of wood is easier with rough ground unless you have large wheels on trolley

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

-

what2do

- Registered user

- Posts: 2853

- Joined: 05 Oct 2012, 08:55

- 80-90 Mem No: 11974

- Location: Salisbury

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

I moved mine on a skateboard about a week ago, it even moved well on the grass. I'd definitely recommend dropping the engine on its own for ease of manoeuverability, had to roll mine about 20 metres, was no bother. Look closely at that photo and be sure to use the 2 lifting points rather than just one which I did for removal resulting in the engine pivoting. Did it properly when refitting and slid into place like a dream. Not sure why but the only hitch I had was that when I tried to install the starter, it just wouldn't engage the fly wheel meaning that it wouldn't push home all the way. Felt like throwing it into the next field. It eventually slid in - it had to as there was no reason for it not to!

Why would the glass be anything other than half full?

'89 panel van, 1.9 DG.

'89 panel van, 1.9 DG.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Thanks all. Yes, I've had the starter in and out several times - doesn't mean I enjoy doing it.

Skateboard left home years ago. Had a look at the pallet and it seems chunky enough. And my castors are 3 inch diameter, so will cope easily with my block paving drive. So I have the makings of a suitable trolley. Point noted about the two lifting eyes.

I've run the wires from engine bay to dashboard this evening, ready to fit the oil pressure and temperature gauges. I'm keen to see what the oil pressure in my DG is like before I take it out. If it's ok then I won't bother to split the case, and will just do a re-seal as originally planned. I've never noticed a problem with oil pressure, but since my 1983 van only has the low pressure sender (between the pushrods) - no BOD circuit - there's very little you can tell without a gauge of some sort.

Skateboard left home years ago. Had a look at the pallet and it seems chunky enough. And my castors are 3 inch diameter, so will cope easily with my block paving drive. So I have the makings of a suitable trolley. Point noted about the two lifting eyes.

I've run the wires from engine bay to dashboard this evening, ready to fit the oil pressure and temperature gauges. I'm keen to see what the oil pressure in my DG is like before I take it out. If it's ok then I won't bother to split the case, and will just do a re-seal as originally planned. I've never noticed a problem with oil pressure, but since my 1983 van only has the low pressure sender (between the pushrods) - no BOD circuit - there's very little you can tell without a gauge of some sort.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

- bigherb

- Registered user

- Posts: 2582

- Joined: 27 Mar 2008, 13:50

- 80-90 Mem No: 5789

- Location: West Kent

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

The followers are designed to rotate with each movement, that is why they are off centre too the cam lobe to stop wearing a groove in the follower.CJH wrote: and about orienting the bore holes 180 degrees apart (probably won't stay that way in use). They'll then be stored in oil, but coated in assembly lube before insertion into the engine, again to minimise that initial drain down.

The oil pumps are the same as twin port beetle/bay engines 111 115 107B, 107A was the smaller single port pump.

1982 Camper 1970 1500 Beetle Various Skoda's, Ariel Arrow

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

bigherb wrote: The followers are designed to rotate with each movement, that is why they are off centre too the cam lobe to stop wearing a groove in the follower.

I had an idea that was the case. Given that the plunger will rotate relative to the body, and therefore the bore holes will inevitably line up occasionally, that can only mean it doesn't matter. If it mattered it would have been easy to engineer a way to prevent the plunger turning in the body. And both of the bore holes are in grooves around their respective parts, evidently designed to allow oil to flow more easily.

I'm no clearer now about what causes the drain down. In fact I'm even doubting what 'drain down' means. Given that the tappet will be a snug fit inside the case bore, it will be difficult for air to replace oil that drains out (hot oil maybe, but tappets mostly drain down after extended idle periods, and for most of that time the oil will be cold and thick). So maybe 'drain down' doesn't mean 'emptying of oil'. Maybe it just means that the oil pressure inside the tappet dissipates, and the plunger is no longer firm against the pushrod. This seems to tally with other reports that it's the tappets that are under load when the engine stops that drain down more quickly.

So, if it's just the plunger being compressed so that there's less volume of oil in the tappet, then clearly that control disk plays an important role. But I can't figure out exactly what that role is. Should it slow the release of oil from inside the plunger, or should it allow oil to flow past it freely so as to let the tappet pump up again quickly?

I've stopped worrying about them, so this is all academic. If these KS tappets work ok, then great. If not, then I've fitted telescopic pushrod tubes so that I can change them if necessary.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

- bigherb

- Registered user

- Posts: 2582

- Joined: 27 Mar 2008, 13:50

- 80-90 Mem No: 5789

- Location: West Kent

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Yes it is the pressure in the plunger dissipating when holding a valve open. Oil grade makes little difference to losing pressure if it is going to lose pressure it will, but a thinner W grade will pump up the tappet quicker.CJH wrote:bigherb wrote:

mean 'emptying of oil'. Maybe it just means that the oil pressure inside the tappet dissipates, and the plunger is no longer firm against the pushrod. This seems to tally with other reports that it's the tappets that are under load when the engine stops that drain down more quickly.

So, if it's just the plunger being compressed so that there's less volume of oil in the tappet, then clearly that control disk plays an important role. But I can't figure out exactly what that role is. Should it slow the release of oil from inside the plunger, or should it allow oil to flow past it freely so as to let the tappet pump up again quickly?

Ratwell has the best explanation, it is for air cooled engines but the tappets are the same and explains the disc.

http://www.ratwell.com/technical/HydraulicLifters.html" onclick="window.open(this.href);return false;

1982 Camper 1970 1500 Beetle Various Skoda's, Ariel Arrow

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

bigherb wrote: Ratwell has the best explanation, it is for air cooled engines but the tappets are the same and explains the disc.

http://www.ratwell.com/technical/HydraulicLifters.html" onclick="window.open(this.href);return false;

Thank you. Yes, I'd read Ratwell a while ago, but I think it takes a few readings and more familiarity with the tappets for it all to sink in. OK, so the tappet pressurises because pressurised engine oil in the tappet bores enters the plunger cavity through the two boreholes (meaning that those boreholes must stay clear, and it explains the grooves), and then it reaches the spring cavity beyond the plunger whenever the check valve opens from inertia.

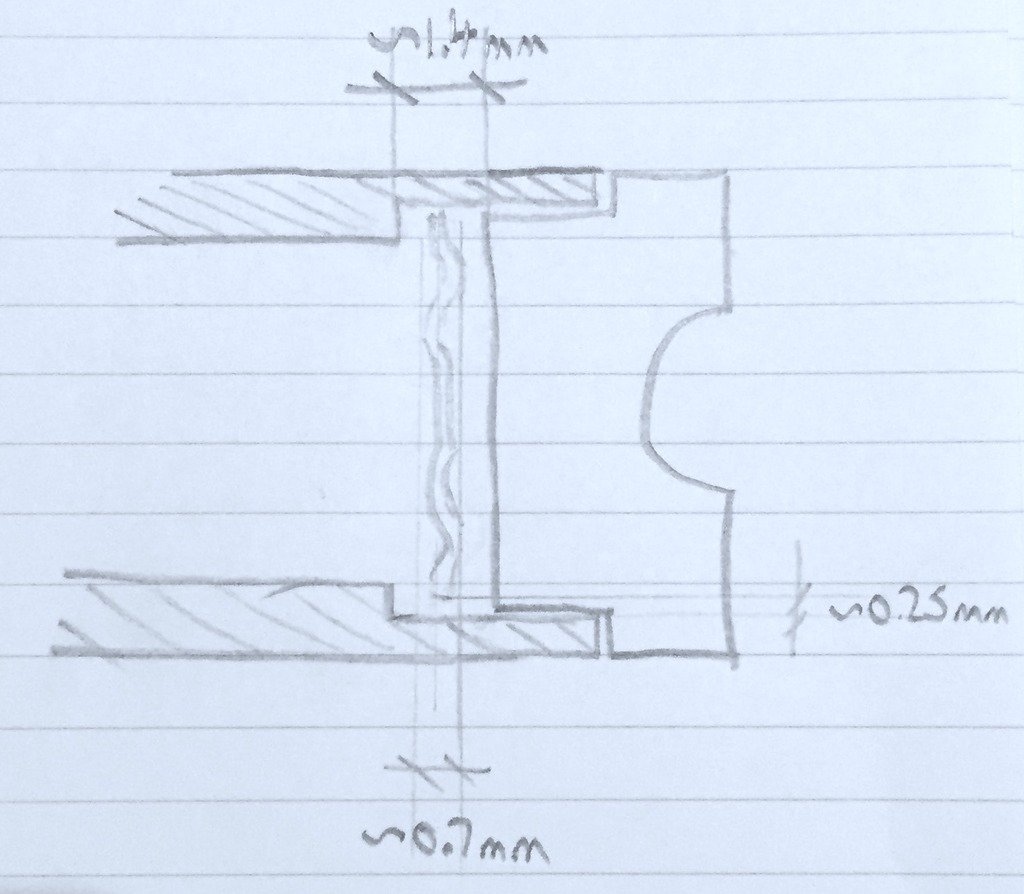

The metering disk is there to let a small amount of pressurised oil out of the plunger cavity and up into the pushrod central bore, to keep the rockers lubricated. So the disk has to float in the small gap between the plunger body and the pushrod seat, to let that small amount of oil past. Here's the diagram I sketched before - I realise I forgot to include the hole in the pushrod seat, which is what allows the oil to reach the rockers.

More on that disk: I was worried as to whether it mattered which way up the disk goes. There are two raised horseshoe impressions in the disk, one on one side, one on the other. I don't think it does matter which way up it is, because in use I think it will tend to be forced against the pushrod seat, so the only way oil can reach the pushrod bore is by seeping round the edge of the disk and then through the gap in whichever horseshoe is pressed against the pushrod seat. Since the gap in both horseshoes is the same, I don't think it matters.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

- bigherb

- Registered user

- Posts: 2582

- Joined: 27 Mar 2008, 13:50

- 80-90 Mem No: 5789

- Location: West Kent

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

You got it. Yes the disc just meters the amount of oil to the rockers although it is not a seep of oil as it is under pressure it is a notable supply the rockers are quite a high load component. No splash lubrication hearCJH wrote: The metering disk is there to let a small amount of pressurised oil out of the plunger cavity and up into the pushrod central bore, to keep the rockers lubricated. So the disk has to float in the small gap between the plunger body and the pushrod seat, to let that small amount of oil past. Here's the diagram I sketched before - I realise I forgot to include the hole in the pushrod seat, which is what allows the oil to reach the rockers.

More on that disk: I was worried as to whether it mattered which way up the disk goes. There are two raised horseshoe impressions in the disk, one on one side, one on the other. I don't think it does matter which way up it is, because in use I think it will tend to be forced against the pushrod seat, so the only way oil can reach the pushrod bore is by seeping round the edge of the disk and then through the gap in whichever horseshoe is pressed against the pushrod seat. Since the gap in both horseshoes is the same, I don't think it matters.

1982 Camper 1970 1500 Beetle Various Skoda's, Ariel Arrow

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

I fitted the oil pressure and temperature gauges today, complete with ignition-switched power and a connection into the dashboard lights so that they illuminate at night. And I'd run a two core cable to the engine bay to connect up to the pressure and temperature senders. The Brickwerks pod makes for a nice tidy installation.

But fitting the senders was a pain. I'm using the Brickwerks sender relocation kit for the pressure sender, and it entails fitting a right-angled banjo bolt into the thread where the low pressure sender goes, between the pushrods. Absolute pig to fit. Oil dribbles out of the hole when you remove the sender, and starting the banjo bolt is very difficult - it's fairly inaccessible, the right angle bend in the bolt makes it difficult to get a socket on, and it has a fine thread that's easy to cross-thread. But I got it fitted and fired up the engine - the gauge didn't work. I realised that I hadn't earthed the sender (temporary location for now - will do a proper job on the new engine), so I walked back to the engine bay and stepped in a pool of oil! It appears the banjo bolt wasn't fully home - and the oil evidently came out under some pressure as it had missed my catch tray.

So I stood and thought about it, realised that fitting the sump plug temperature sender was also going to be a messy job with a sump full of oil, and I'm afraid I gave up. I drained the rest of the oil, cleared up the spillage, and decided to live without knowing what my DG oil pressure is like.

On the plus side, making my pallet-on-casters engine trolley went without a hitch.

But fitting the senders was a pain. I'm using the Brickwerks sender relocation kit for the pressure sender, and it entails fitting a right-angled banjo bolt into the thread where the low pressure sender goes, between the pushrods. Absolute pig to fit. Oil dribbles out of the hole when you remove the sender, and starting the banjo bolt is very difficult - it's fairly inaccessible, the right angle bend in the bolt makes it difficult to get a socket on, and it has a fine thread that's easy to cross-thread. But I got it fitted and fired up the engine - the gauge didn't work. I realised that I hadn't earthed the sender (temporary location for now - will do a proper job on the new engine), so I walked back to the engine bay and stepped in a pool of oil! It appears the banjo bolt wasn't fully home - and the oil evidently came out under some pressure as it had missed my catch tray.

So I stood and thought about it, realised that fitting the sump plug temperature sender was also going to be a messy job with a sump full of oil, and I'm afraid I gave up. I drained the rest of the oil, cleared up the spillage, and decided to live without knowing what my DG oil pressure is like.

On the plus side, making my pallet-on-casters engine trolley went without a hitch.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

-

what2do

- Registered user

- Posts: 2853

- Joined: 05 Oct 2012, 08:55

- 80-90 Mem No: 11974

- Location: Salisbury

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

I fitted the BW remote kit a while ago whilst at Itchy's, I agree that it isn't the best to fit, half an inch longer hose would have helped and trying to get the angled banjo around the pushrod tubes reminded me of a chinese puzzle.

Why would the glass be anything other than half full?

'89 panel van, 1.9 DG.

'89 panel van, 1.9 DG.

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

One of you two should email Brickwerks about it.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Chris, those new tappets do they have the concave surface on the cam end?

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

itchyfeet wrote:Chris, those new tappets do they have the concave surface on the cam end?

No - perfectly flat, why? You've got be worried now - the ones I salvaged from the case that I started with are concave.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ