What electric soldering iron?

Moderators: User administrators, Moderators

- Ian and Lins

- Registered user

- Posts: 1906

- Joined: 27 Apr 2007, 13:18

- 80-90 Mem No: 3532

- Location: Rushden, Northants (God's waiting room)

- Contact:

What electric soldering iron?

I need a new 240v solderning iron and wondered what wattage to buy. I've got a gas powered one which is fine for larger vehicle cables but will a high wattage 'leccy one still work well on finer cables?

Are we going on anything else?

1985 Petrol 1.9 A/S Hightop

1985 Petrol 1.9 A/S Hightop

-

spherehopper

- Registered user

- Posts: 87

- Joined: 14 Mar 2017, 09:42

- 80-90 Mem No: 1

- Location: Hants

Re: What electric soldering iron?

I have a Weller 60W (W60D) that I use on anything from fine cable to 3mm copper. It has lasted me over 30 years so if you're planning a keeper then buy decent. You will find a solder sucker useful for cleaning up old joints prior to resoldering (solder tape is carp).

CPC and RS Components a good source for tools.

Remember to make a good mechanical joint first. It is not recommended to use a soldered joint as the structural method of holding cables together, especially in a high vibration environment like a motor vehicle. I prefer crimp joints where possible.

A good source of stuff is http://www.vehicle-wiring-products.eu/" onclick="window.open(this.href);return false;

(No connection, just a happy customer).

CPC and RS Components a good source for tools.

Remember to make a good mechanical joint first. It is not recommended to use a soldered joint as the structural method of holding cables together, especially in a high vibration environment like a motor vehicle. I prefer crimp joints where possible.

A good source of stuff is http://www.vehicle-wiring-products.eu/" onclick="window.open(this.href);return false;

(No connection, just a happy customer).

- Oldiebut goodie

- Registered user

- Posts: 7525

- Joined: 18 Apr 2008, 01:19

- 80-90 Mem No: 11135

- Location: Eastern Angle

Re: What electric soldering iron?

Solder braid is fine - just add extra flux and it will wick up all the solder easily. They either sell it with no flux in or absolute minimum. Scrap co-ax cable is a good source for those larger jobs.

Various wattage depending upon the job. 18w, 30w, 75w, 150w all get used by me.

I hate crimp joints with a vengeance - some that I have come across pull apart with the slightest strain ( had one in on a heater the other day), they are also a source of corrosion if used externally. I prefer solder with adhesive shrink tube if there is a chance of vibration around a joint. If you have seen crimps on old marine wiring harnesses you can understand my loathing for them. Just salt air gets into them and corrodes the joint.

Various wattage depending upon the job. 18w, 30w, 75w, 150w all get used by me.

I hate crimp joints with a vengeance - some that I have come across pull apart with the slightest strain ( had one in on a heater the other day), they are also a source of corrosion if used externally. I prefer solder with adhesive shrink tube if there is a chance of vibration around a joint. If you have seen crimps on old marine wiring harnesses you can understand my loathing for them. Just salt air gets into them and corrodes the joint.

1.6D 2019 VW T-Cross

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

- Oldiebut goodie

- Registered user

- Posts: 7525

- Joined: 18 Apr 2008, 01:19

- 80-90 Mem No: 11135

- Location: Eastern Angle

Re: What electric soldering iron?

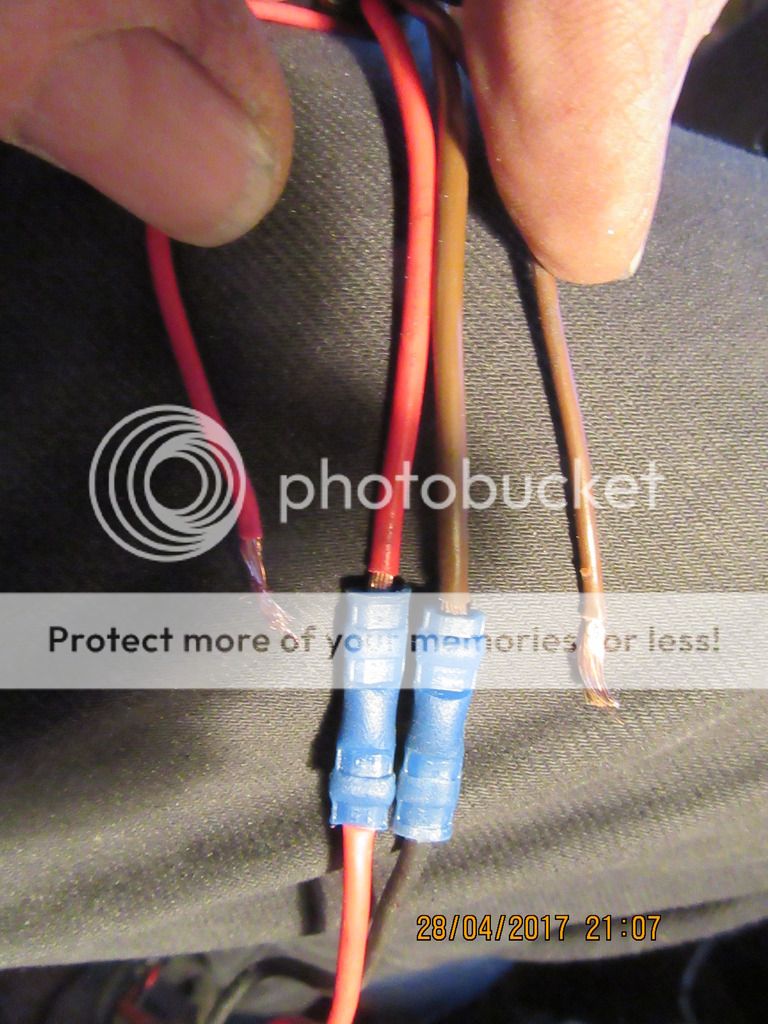

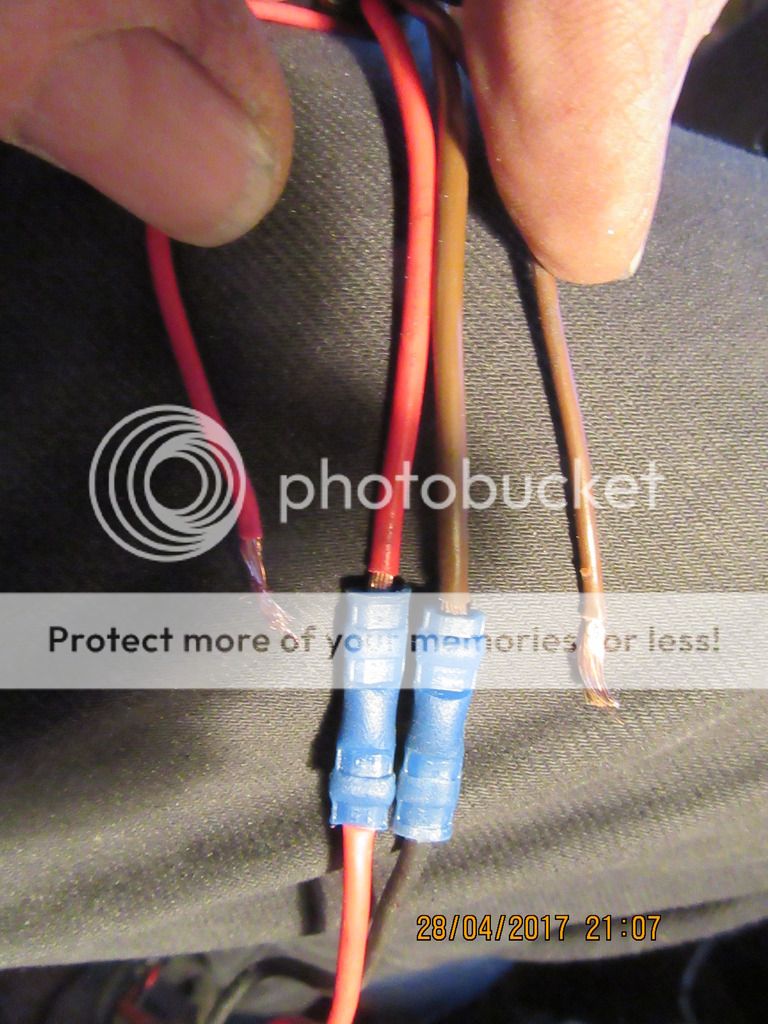

And this just in on a heater today:

Gentle pull and:

HATE HATE HATE

Give me solder over this rubbish any time.

Gentle pull and:

HATE HATE HATE

Give me solder over this rubbish any time.

1.6D 2019 VW T-Cross

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

- nicq

- Registered user

- Posts: 1185

- Joined: 24 Sep 2011, 19:03

- 80-90 Mem No: 10290

- Location: Cranleigh Surrey

Re: What electric soldering iron?

There is nothing wrong with crimping if done properly with the correct tools. What you are showing is neither.

All cars and aircraft are proof of that if done correctly they are the most reliable connections you can make cheaply.

All cars and aircraft are proof of that if done correctly they are the most reliable connections you can make cheaply.

2.1 Twin slider

- Oldiebut goodie

- Registered user

- Posts: 7525

- Joined: 18 Apr 2008, 01:19

- 80-90 Mem No: 11135

- Location: Eastern Angle

Re: What electric soldering iron?

This is the type of crimping that is ubiquitous amongst diy repairs. A proper crimp is better, yes but this is what is seen everywhere.

Cars are not proof of correct crimping being the best way to join wiring where it is exposed to external elements - look at the number of posts concerning starter motor factory crimped terminals. Also alternator exciter cable crimps. Crimping was designed to speed up production not as a best way forward.

Cars are not proof of correct crimping being the best way to join wiring where it is exposed to external elements - look at the number of posts concerning starter motor factory crimped terminals. Also alternator exciter cable crimps. Crimping was designed to speed up production not as a best way forward.

1.6D 2019 VW T-Cross

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

- nicq

- Registered user

- Posts: 1185

- Joined: 24 Sep 2011, 19:03

- 80-90 Mem No: 10290

- Location: Cranleigh Surrey

Re: What electric soldering iron?

Oldiebut goodie wrote:This is the type of crimping that is ubiquitous amongst diy repairs. A proper crimp is better, yes but this is what is seen everywhere.

Cars are not proof of correct crimping being the best way to join wiring where it is exposed to external elements - look at the number of posts concerning starter motor factory crimped terminals. Also alternator exciter cable crimps. Crimping was designed to speed up production not as a best way forward.

If you check 100 solder joints I would bet the quality would be widely different. If you were to check the same number of crimps, they should be the same. Solder joints are only as good as the operator, and take considerably longer.

The number of posts on the forum on bad connections does not take into account the fact no maintenance is ever carried out on connections as opposed to just about every other component on the van.

Leave your brakes for 25 years and see how they work, then you comment about a bad connection on the starter !

2.1 Twin slider

-

spherehopper

- Registered user

- Posts: 87

- Joined: 14 Mar 2017, 09:42

- 80-90 Mem No: 1

- Location: Hants

Re: What electric soldering iron?

They are pretty nasty DIY crimps. You can buy a crimp tool for a fiver, or one for £500. There is a heck of a difference between DIY jobs you show above and a professional job. Solder wasn't designed as a cable joining medium but it often used as such in vehicles. If in doubt, crimp then solder up the crimp but don't rely on solder alone to hold your cables together for 5-10 years.

- Oldiebut goodie

- Registered user

- Posts: 7525

- Joined: 18 Apr 2008, 01:19

- 80-90 Mem No: 11135

- Location: Eastern Angle

Re: What electric soldering iron?

They were crimped on by the garage that fitted the heater originally. If a garage cannot crimp correctly there is small chance of diy ers getting good results. There are professionals and then there are professionals. Solder was evolved from the need to join two pieces of metal, a properly soldered joint will exceed the parent metal in strength and the parent will fail before the joint on a load test. Soldering of cables on vehicles was carried out long before you were born most probably and has a longer pedigree than crimping. I should think that if you look at 1920s vehicles you will find that the soldering is still intact - slightly longer than your figure, plucked from the sky, of 5 - 10 years.

1.6D 2019 VW T-Cross

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

200hp VW T6

1̶Y̶ ̶1̶9̶8̶7̶ ̶H̶i̶-̶t̶o̶p̶ ̶C̶a̶r̶a̶v̶e̶l̶l̶e̶

5̶0̶8̶d̶ ̶M̶e̶r̶c̶

-

spherehopper

- Registered user

- Posts: 87

- Joined: 14 Mar 2017, 09:42

- 80-90 Mem No: 1

- Location: Hants

Re: What electric soldering iron?

Oldiebut goodie wrote:If a garage cannot crimp correctly there is small chance of diy ers getting good results

Ha ha. I'm not sure the label "garage" endorses good results. The motor trade in the UK has a pretty dodgy reputation and I think a DIYer could often produce better results assuming they had the knowledge, skill and tools for the job since they have unlimited time compared to a profit making venture.

Oldiebut goodie wrote:Solder was evolved from the need to join two pieces of metal

Correct, and wire is a metal. My emphasis was on making a secure mechanical joint before soldering when many cable joins I've seen on vehicles are nose to tail held together by only the solder. I'd argue the difference in metals and solder being a relatively soft compound opens itself up to risk of separation under vibration.

Oldiebut goodie wrote:Soldering of cables on vehicles was carried out long before you were born most probably

Slightly condescending since I was born in the first few days of 1958. Probably one of the older people on here as you may be if I judge by your username.

Oldiebut goodie wrote:I should think that if you look at 1920s vehicles you will find that the soldering is still intact - slightly longer than your figure, plucked from the sky, of 5 - 10 years.

And I bet those joints were mechanically fixed prior to soldering.

I only quote from experience. I did a five year electronic engineering apprenticeship which included periods under training and on the factory floor making military communications equipment. My soldering skills were learned before that when I was a radio amateur in the early 1970s age 14 and modified old transmitters and receivers. Later I spent many years as a electronics maintenance engineer working in high vibration environments so I can speak from experience. I wouldn't rely on solder to join cables on a vehicle. Secure it mechanically first, then solder if you wish. Since many joints are likely to be in inaccessible places, I'd prefer a watertight crimp made with proper components and the correct tool, not a £5 handheld tool and cheap crimp as it appears in the picture above. If joining multiple cables in a loom that might need to come apart, a Molex plug/socket would be the way I'd do it. They are a crimp based product.

I now fly one of the most modern commercial aeroplanes (the 787, hence my username) and Boeing use crimped terminals on the ends of cables to make connections to other equipment although I expect one of their crimp tools cost more than a fully restored Westie!