I have decided to just replace the exhaust guides, the Inlet are not so bad and can stay for another day, I assume the inlets have a bit more lubrication from the fuel.

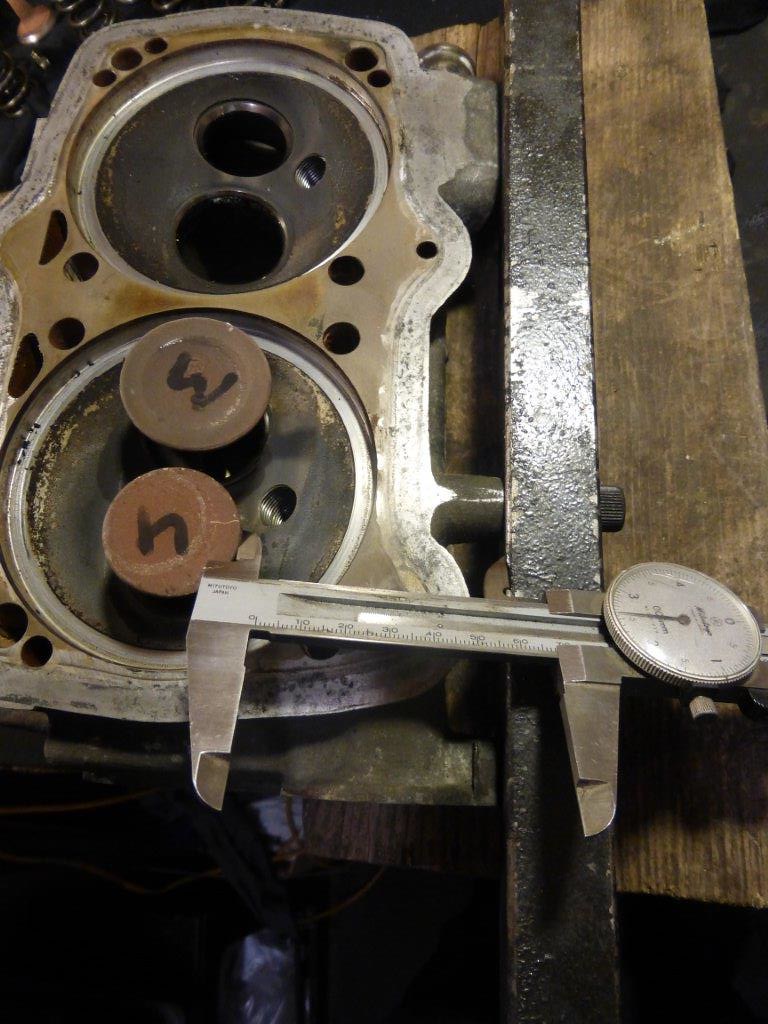

Note Inlet valves are 8mm diameter and exhaust 9mm diameter!!

I have an old head so I practised removing and refitting the guides first as I have not done this before, I had a few problems particularly with galling of the thread but that may have been low quality threaded bar.

The normal method, so I have read, is to tap the guide then using a long bolt or threaded bar and a tube spacer wind it out. Easier said than done, I found if you didn't tap right through the bolt hits the end of the thread and then starts expanding the guide which stops it moving, I snapped a bolt doing this so I moved to tapping right through not sure if it's the best way but it's what worked for me.

There are problems with tapping right through in that the tap is not long enough so I counter bored 20mm from both ends and just tapped the middle section.

Counter bore from top was 10mm followed by 11mm drill, counter bore from valve side was just 10mm

P1060362

P1060362 by

Paul_Barr, on Flickr

I used M8 studding carefully slid through the inlet valve guide acts as a good guide to drilling and tapping square, vacuum cleaner to reduce the amount of swarf left.

P1060383

P1060383 by

Paul_Barr, on Flickr

Keep pulling the drill out to check it's drilling square and evenly

P1060387

P1060387 by

Paul_Barr, on Flickr

then drill from valve side

P1060390

P1060390 by

Paul_Barr, on Flickr

using two M10 tap sizes, first runs through easy the second is a bit harder, never going to get in there with a tap wrench so used a battery drill on slow, and kept going forwards and backwards, used grease.

P1060395

P1060395 by

Paul_Barr, on Flickr

P1060396

P1060396 by

Paul_Barr, on Flickr

Checked the studding threaded through easily

P1060399

P1060399 by

Paul_Barr, on Flickr

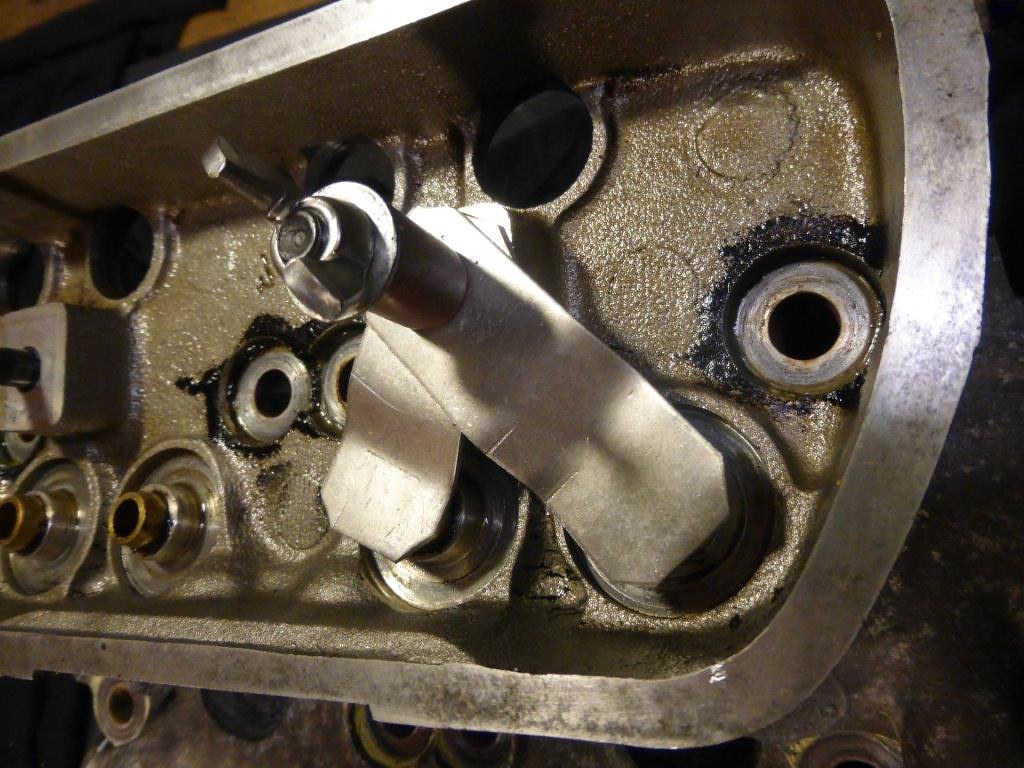

spacer tube and washer two nuts locked off on the end, a hardened bolt would be better I think

P1060400

P1060400 by

Paul_Barr, on Flickr

wind it out

P1060401

P1060401 by

Paul_Barr, on Flickr

P1060403

P1060403 by

Paul_Barr, on Flickr

clean holes out removed as much swarf as possible with a rag first then washed it all down with paraffin

P1060404

P1060404 by

Paul_Barr, on Flickr

P1060405

P1060405 by

Paul_Barr, on Flickr

P1060406

P1060406 by

Paul_Barr, on Flickr

P1060288 by Paul_Barr, on Flickr

P1060288 by Paul_Barr, on Flickr P1060291 by Paul_Barr, on Flickr

P1060291 by Paul_Barr, on Flickr P1060292 by Paul_Barr, on Flickr

P1060292 by Paul_Barr, on Flickr P1060293 by Paul_Barr, on Flickr

P1060293 by Paul_Barr, on Flickr P1060294 by Paul_Barr, on Flickr

P1060294 by Paul_Barr, on Flickr P1060295 by Paul_Barr, on Flickr

P1060295 by Paul_Barr, on Flickr P1060296 by Paul_Barr, on Flickr

P1060296 by Paul_Barr, on Flickr P1060298 by Paul_Barr, on Flickr

P1060298 by Paul_Barr, on Flickr