I could have had them made locally

WBX

Moderators: User administrators, Moderators

- Aidan

- Trader

- Posts: 7200

- Joined: 11 Oct 2005, 19:21

- 80-90 Mem No: 742

- Location: Llanfyllin, mid Wales : )

Re: WBX

I just bought 500 off 7mmx1mmx20mm yellow passivated HT machine screws, 11mm hex head, as Wurth no longer do them in 100s, had to come from Germany, actually made in Italy

I could have had them made locally

I could have had them made locally

AIDAN

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: WBX

Interesting, 20mm is still too long though.

I take it you mean tap the Cam SB, do you know how thick it is, looks to me about 6mm

If so you need a 12mm long screw M7x1 and then what to lock it in place? peen the end over? a bit crude.

I wonder if the screw head would touch the oil pump, will look later.

Do you see any reason why it would need to be high tensile?

http://www.superkart.it/engine-spare-pa ... 5-tm-49727" onclick="window.open(this.href);return false;

https://www.kartingshop.nl/en/link/3110 ... x12-5.html" onclick="window.open(this.href);return false;

Needs to be an easier way for people to swap cam gears

I take it you mean tap the Cam SB, do you know how thick it is, looks to me about 6mm

If so you need a 12mm long screw M7x1 and then what to lock it in place? peen the end over? a bit crude.

I wonder if the screw head would touch the oil pump, will look later.

Do you see any reason why it would need to be high tensile?

http://www.superkart.it/engine-spare-pa ... 5-tm-49727" onclick="window.open(this.href);return false;

https://www.kartingshop.nl/en/link/3110 ... x12-5.html" onclick="window.open(this.href);return false;

Needs to be an easier way for people to swap cam gears

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

-

silverbullet

- Trader

- Posts: 17303

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: WBX

Loctite. Chemicals win in this environment. I did look at getting some button-head ones made but it was a cost thing. At 4 per engine it would make them look expensive and/or I would never use them all up!

The tap we already have (modular alloy wheels use M7 x1 Titanium alloy screws)

Sent by Morse code from the bunker

The tap we already have (modular alloy wheels use M7 x1 Titanium alloy screws)

Sent by Morse code from the bunker

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys

-

silverbullet

- Trader

- Posts: 17303

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: WBX

PS most specials tend to come in the highest tensile rating by default

Sent by Morse code from the bunker

Sent by Morse code from the bunker

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: WBX

looks to me like the standard hex heads on the link above ( some sort of go kart clutch bolt) would fit, may have to get some

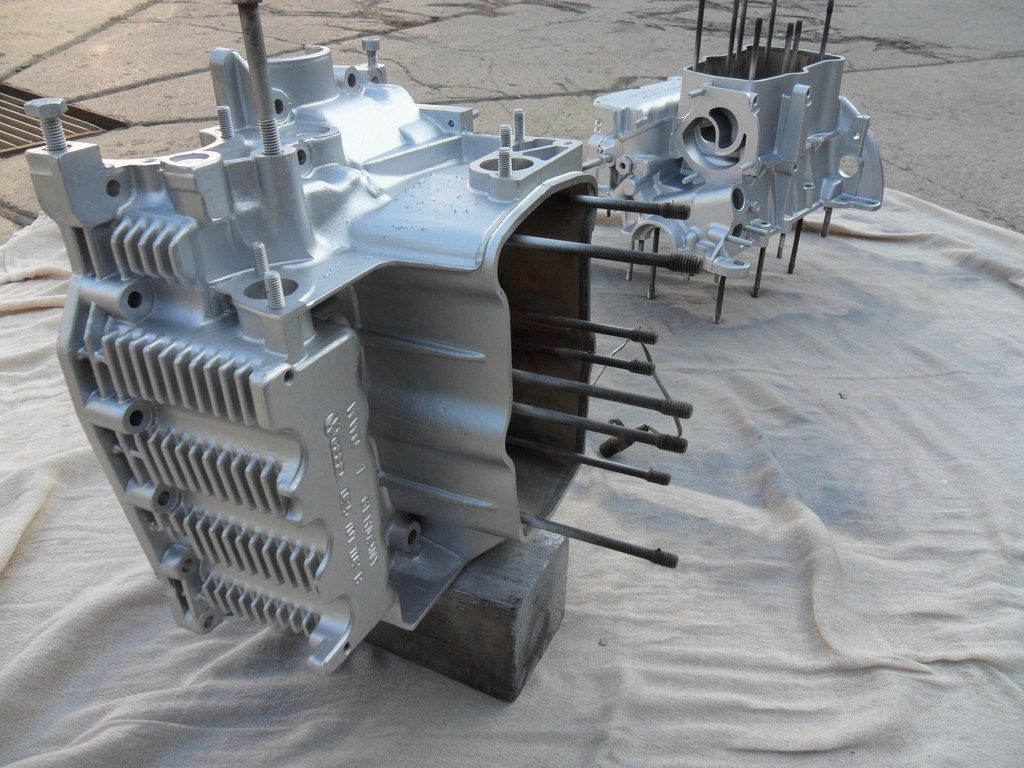

P1040654 by Paul_Barr, on Flickr

P1040654 by Paul_Barr, on Flickr

P1040654 by Paul_Barr, on Flickr

P1040654 by Paul_Barr, on Flickr

Last edited by itchyfeet on 22 Dec 2017, 15:43, edited 1 time in total.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

-

silverbullet

- Trader

- Posts: 17303

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: WBX

Think you will find that a regular cap head will foul the back of the oil pump at the bottom.

Sent by Morse code from the bunker

Sent by Morse code from the bunker

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: WBX

these are not cap heads, look like reduced height hex

http://www.superkart.it/engine-spare-pa ... 5-tm-49727" onclick="window.open(this.href);return false;

http://www.superkart.it/engine-spare-pa ... 5-tm-49727" onclick="window.open(this.href);return false;

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

-

silverbullet

- Trader

- Posts: 17303

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: WBX

Sorry. Didnt follow the link. Might just do it if you can get a socket on them.

Sent by Morse code from the bunker

Sent by Morse code from the bunker

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: WBX

Yeh ^^^^^^^looks great Jason, good pics

Mine got it's heads fitted tonight, always a worry when torqueing the head nuts but all went well

Got to make another thin 0.07mm paper oil pump gasket, the Elring gasket in the kit 0.25mm that's thicker than the aftermarket ones from Brickwerks and VWH at 0.15mm

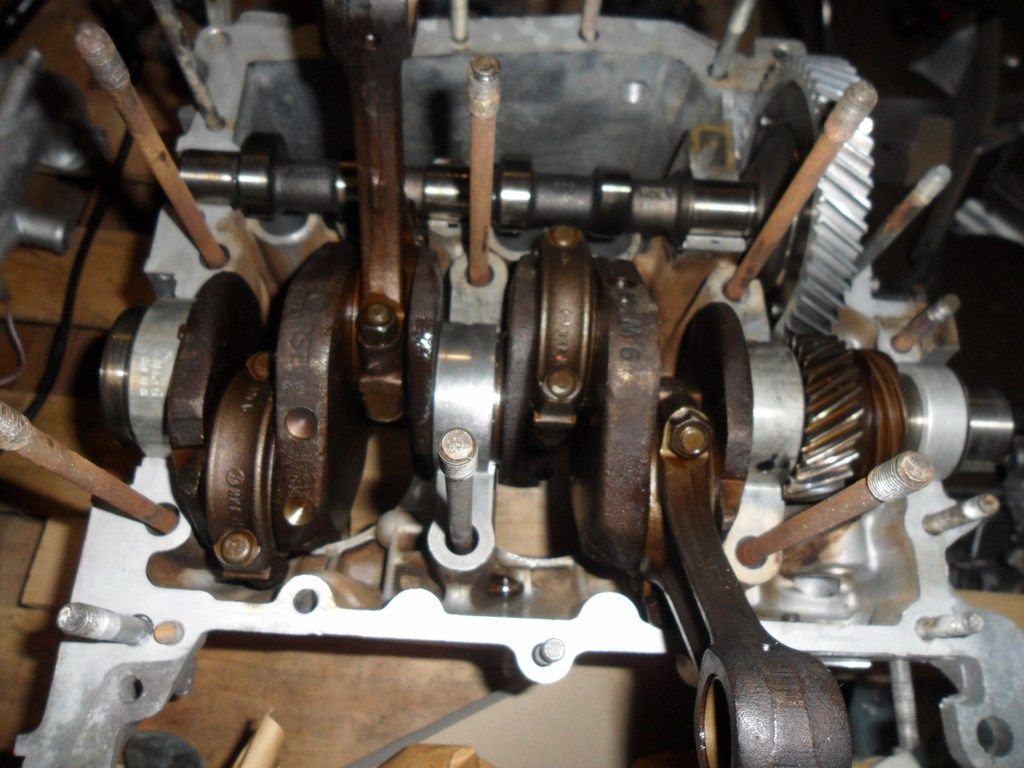

P1040672 by Paul_Barr, on Flickr

P1040672 by Paul_Barr, on Flickr

Mine got it's heads fitted tonight, always a worry when torqueing the head nuts but all went well

Got to make another thin 0.07mm paper oil pump gasket, the Elring gasket in the kit 0.25mm that's thicker than the aftermarket ones from Brickwerks and VWH at 0.15mm

P1040672 by Paul_Barr, on Flickr

P1040672 by Paul_Barr, on Flickr

Last edited by itchyfeet on 22 Dec 2017, 15:44, edited 1 time in total.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

-

Jawin89

- Registered user

- Posts: 190

- Joined: 01 Feb 2014, 09:04

- 80-90 Mem No: 13200

- Location: Gloucestershire

Re: WBX

I know what you mean about the head nuts, worrying times.

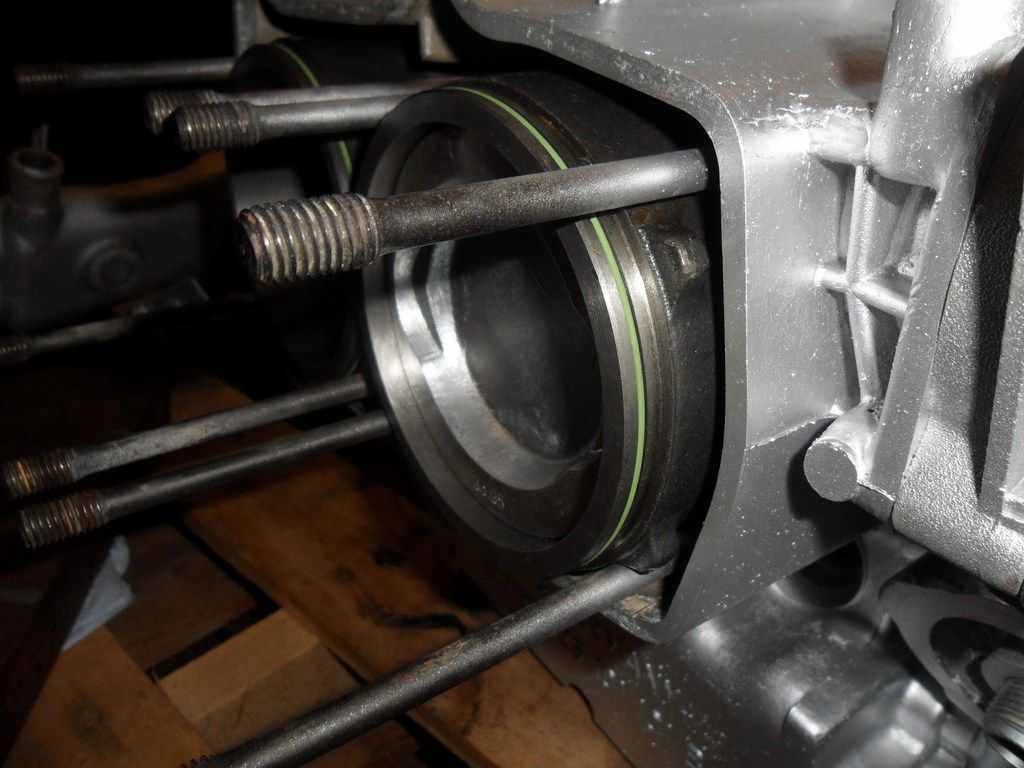

I used a very thin bead of Reinzosil sealant on the oil pump cover to make sure it sealed correctly. It was applied very carefully with a thin piece of wire as not to spread and foul the pump itself. Controversial I know but that was the solution I came up with.

I used a very thin bead of Reinzosil sealant on the oil pump cover to make sure it sealed correctly. It was applied very carefully with a thin piece of wire as not to spread and foul the pump itself. Controversial I know but that was the solution I came up with.

1989 1.9 WBX pop top

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: WBX

Jawin89 wrote:I know what you mean about the head nuts, worrying times.

I used a very thin bead of Reinzosil sealant on the oil pump cover to make sure it sealed correctly. It was applied very carefully with a thin piece of wire as not to spread and foul the pump itself. Controversial I know but that was the solution I came up with.

I thought about that too but using the yellow sealant for head nuts, be interesting to see how you get on with that, the pump can push 5 bar cold before the relief valve goes.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: WBX

I can't help thinking you loose as much pressure from the gap between pump and engine case on the outlet.

I used a smear of the yellow head nut sealant last time.

I used a smear of the yellow head nut sealant last time.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks