Oil Pressure Issues WBX

Moderators: User administrators, Moderators

- ghost123uk

- Registered user

- Posts: 6855

- Joined: 10 Mar 2006, 10:15

- 80-90 Mem No: 2585

- Location: John in Malpas, in the very S. W. part of Cheshire.

- Contact:

Re: Oil Pressure Issues WBX

The suspense is killing - Elite ?

Got a new van, but it's a 165bhp T4 [shock horror] Accurate LPG Station map here

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Oil Pressure Issues WBX

Mojoh wrote: the pressure is controlled from the Pressure relief valve

We discussed this recently.

https://club8090.co.uk/forum/viewtopic.p ... 5#p8084363" onclick="window.open(this.href);return false;

It appears that on an Aircooled this is called a thermostatic valve allows a bypass of oil with temperature

link courtesy of Silverbullet

http://www.volkspage.net/technik/ssp/ssp/SSP_24.PDF" onclick="window.open(this.href);return false;

On a wbx it does not have a thermostatic function it simply vents back to just above the oil pick up pipe when pressure is too high.

The venting pressure is dictated by the spring pressure and preload and my measurements ( on the post above) indicated it would be around 5 bar

That seems to be conveniently about the max I ever see on my oil pressure gauge when cold and revved.

So when hot and oil pressure is likely below 5 bar at the valve ( also high pressure switch is here) this valve may never be activated unles revs are high, as it's after the oil filter even a blocked filter won't activate it.

diagram below courtesy of Bigherb but it's not accurate, the HP switch is where it says main gallery, right next to the pressure relief valve.

The Low pressure switch is not in the main gallery as shown it's off a drilling right next to the camshaft feed, so poor camshaft/bearings or badly fitting tappets will leak flow close to the point the pressure is measured.

It was noted by Kevtherev that when he fitted a gauge to the high pressure switch location it never dropped below about 40psi (2.5 bar) so the pressure by the pump will likely be much higher than the pressure by the camshaft.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

- Aidan

- Trader

- Posts: 7195

- Joined: 11 Oct 2005, 19:21

- 80-90 Mem No: 742

- Location: Llanfyllin, mid Wales : )

Re: Oil Pressure Issues WBX

it's not Elite

Last edited by Aidan on 27 Aug 2015, 06:11, edited 1 time in total.

AIDAN

Re: Oil Pressure Issues WBX

KINGPRAWN wrote:Hey .. Feel your pain here !!!

I spent years with pitifully low op .. I had a recon motor not long after I bought the van so although I was probably 10 years in I refused to believe that the engine needed major work ! I tried everything... And although even after fitting gauges to and replacing pressure switch, relief valve, oil pump and anything else I could think of the only thing that helped was "Mobil 10/60 from halfords expensive but gave me half a bar more, which when idle was virtually zero was a lot across the range !!! I lived with it like that for years and it never sounded anything other that sewing machine quiet and smooth .. But always in the back of your mind is the Big Bang !!! So last year I binned it before it binned me and went TDI ... BEST MONEY I EVER SPENT ... EVER !!!! And got £600 for the old engine and exhaust ( which was stainless and syncro) ..

This is hardly helping the survival of one of the finest engines to come out of VW. We will never ever see another WBX.... history. Whether you understand it or not, it will be saved, reconditioned and tweeked. I'm glad you like your TDi.... the world if full of them!.... Enjoy.

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Oil Pressure Issues WBX

Welcome to 8090 whoever you are

WBX rocks IMO

Still learning every day about them.

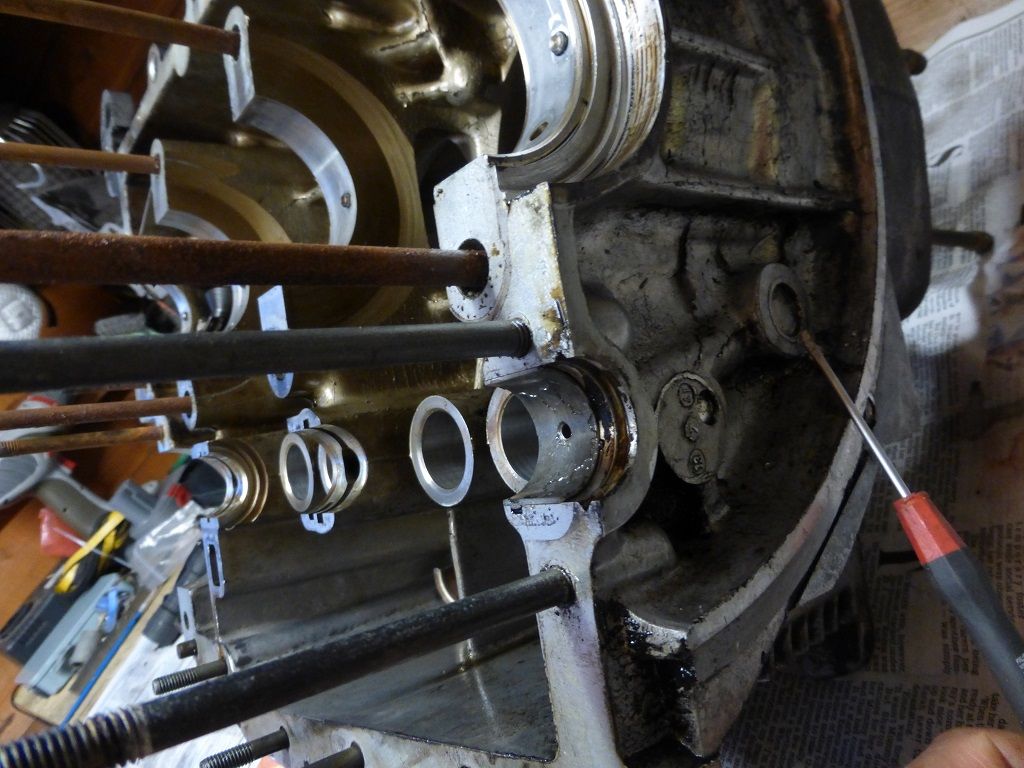

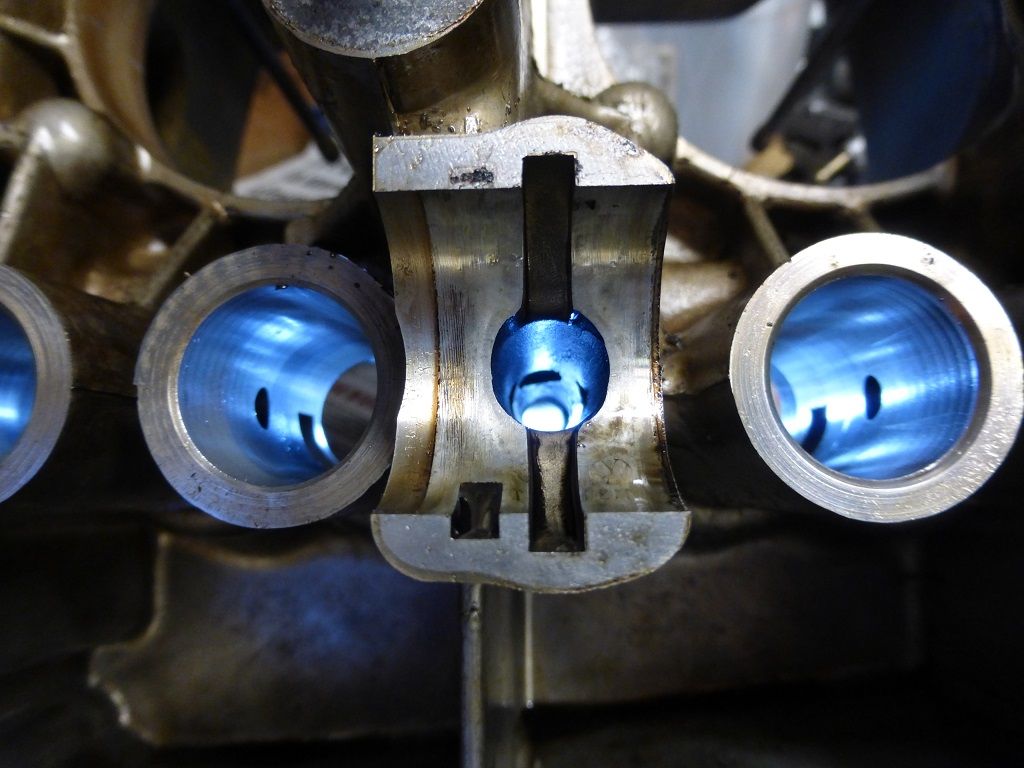

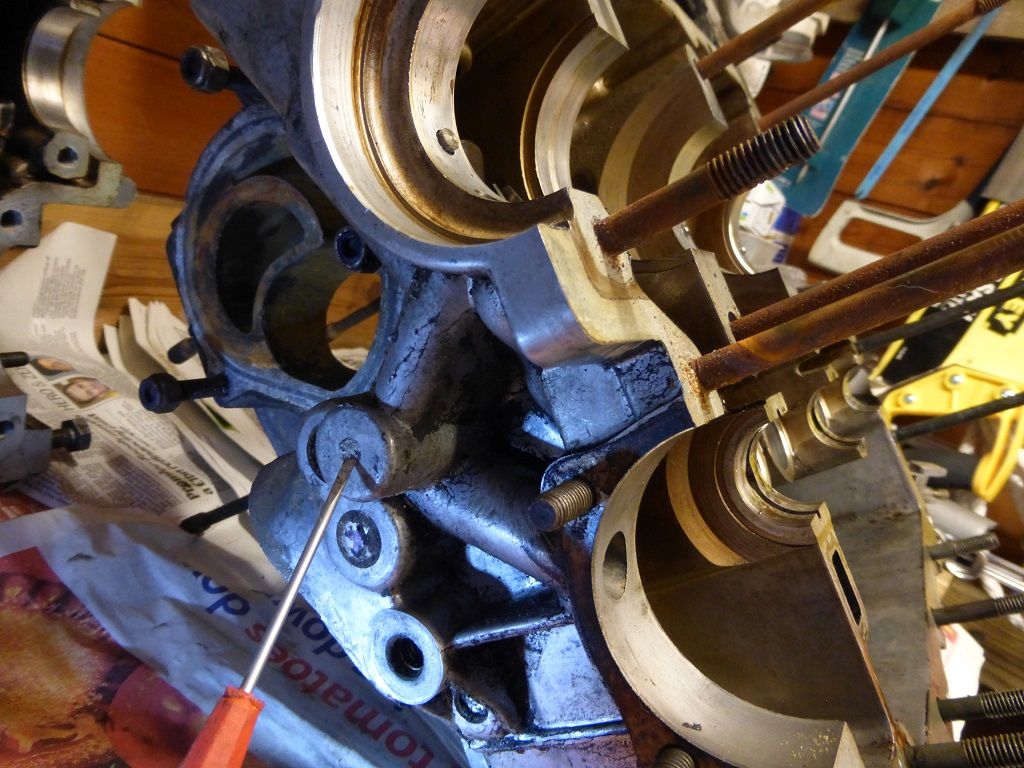

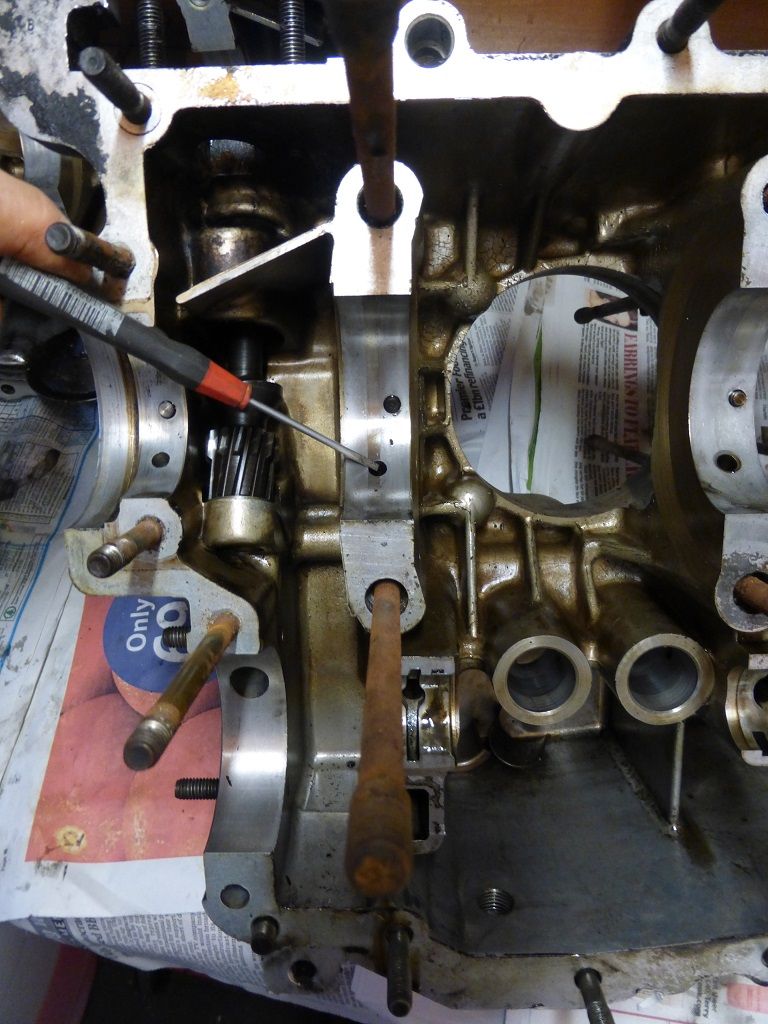

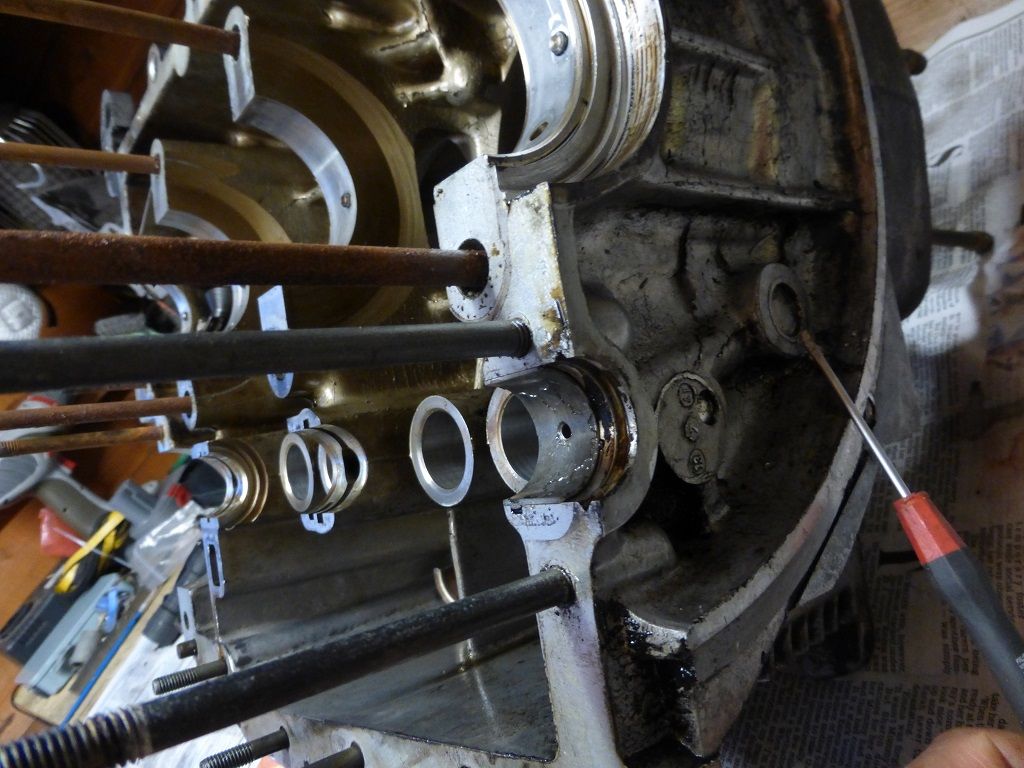

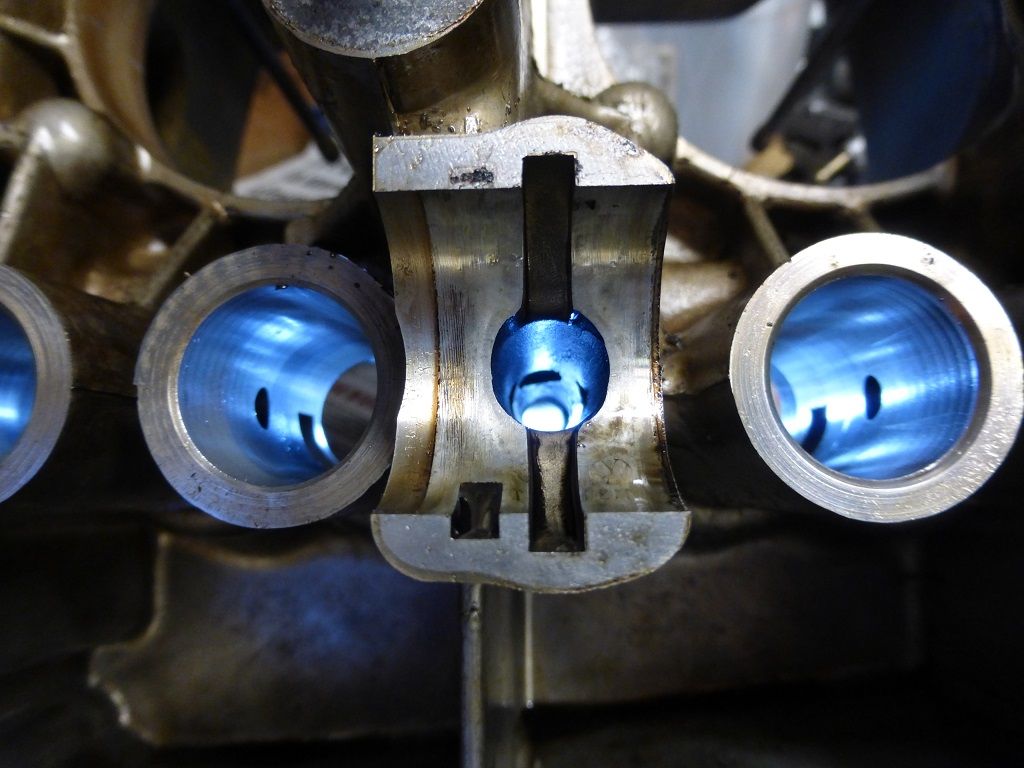

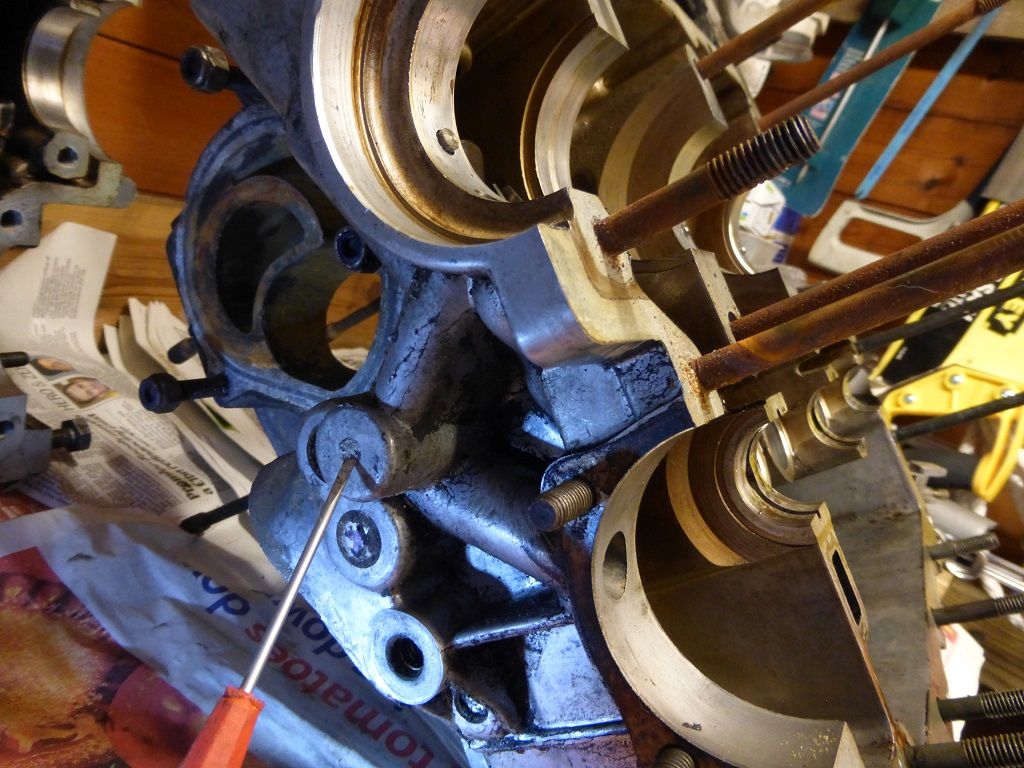

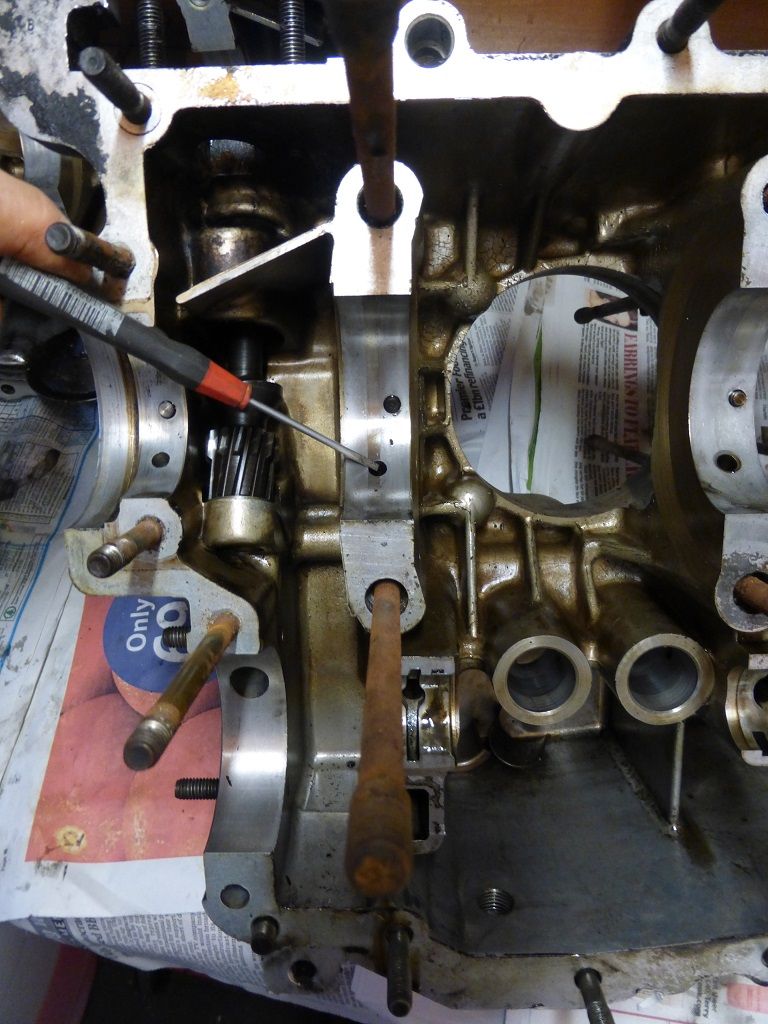

main gallery runs from here to here

this is the low pressure switch location which is drilled to the central camshaft bearing which in turn feeds the other side tappets by feeding around the camshaft bearing.

it can be seen that this drilling is made from the main gallery to the low pressure switch /camshaft drilling from the point indicated in the water jacket which has then been plug welded, the low pressure switch drilling also feeds tappets, these are steel and run in the aluminium crankcase with no lining so once worm will leak oil pressure forever.

another plug welded drilling is this which feeds the front main bearings by also being drilled to the main gallery

Some of these 'drillings' could be removable pins in the casting tool but most are probably too thin and long, more likely drilled.

WBX rocks IMO

Still learning every day about them.

main gallery runs from here to here

this is the low pressure switch location which is drilled to the central camshaft bearing which in turn feeds the other side tappets by feeding around the camshaft bearing.

it can be seen that this drilling is made from the main gallery to the low pressure switch /camshaft drilling from the point indicated in the water jacket which has then been plug welded, the low pressure switch drilling also feeds tappets, these are steel and run in the aluminium crankcase with no lining so once worm will leak oil pressure forever.

another plug welded drilling is this which feeds the front main bearings by also being drilled to the main gallery

Some of these 'drillings' could be removable pins in the casting tool but most are probably too thin and long, more likely drilled.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

Re: Oil Pressure Issues WBX

Some more findings after a day of Oil Pumps out & in again. (not so easy with the engine in situ).

Firstly, we looked at three oil pumps. Here are our findings.

Febi Bilstein. Standard Replacement Pump. The delivery measure of this pump was only 'just' adiquate and gave rise to the sporadik inturuptions of the buzzer from doom when the oil was hot & the engine running at 2,500 rpm.

However, the build quality and gear meshing were good enough and had the buzzer not been working or annoying, I'm sure the engine would be fine. Would be a good fit to the earlier WBX Engines.

Then we looked at the Shardek Pumps. Two types, the standard & the higher delivery units. Both pumps were within very fine tollerences, perfect fitting & delivering faultlessly. The higher delivery unit sure got rid of the buzzer of doom syndrome, so that was a plus.... but (read about gaskets).

Lastly, we got our hands on a Mexican Pump Unisia. (standard delivery). The tollerences were (to us) totally unacceptable (big gaps in the gears and housing), so we rejected the pump without fitting. From the three manufacturers, this one was a definate no.

Then we went on to experiment with gaskets (those between the pump body and the cover plate). Shardek supplied the thinnest of these, but sealing the pump tight proved difficult, especially on the higher delivery unit. The slightly thicker gaskets were easier to seal. There is of course a pay back, the thicker the gasket, the more loss of pressure, but this (in our tests) proved to be very very little indeed. The tollerences in the gears & casing gaps seemed to be more crutial, so it's a bit of give and take. I'd rather go for the thicker gasket (within reason), than poor finish on the gears/case. If you go for the high volume pump, you can easily afford a slightly thicker cover gasket and be assured of 'no leaks'.

Finally, the Pump Cap (plate). We looked at three, one claimed to be VW, but was painted black on both sides, which meant, the paint would end up in the oil????, so we dumped that one.

The other two were basically engineered steel plates. The smoother one looked great, but wasn't so easy to seal.

The second was slightly more engineered in finish and sealed easily. The securing nuts have special rubber sealing rings and in the case of the high delivery units need tightening tighter than is recomended by VW.

An oil pump is the heart of an Engine. When it works, you wouldn't even know it was there and when it doesn't, you'll know!..... hope this helps someone, somewhere.

Mojoh.

Firstly, we looked at three oil pumps. Here are our findings.

Febi Bilstein. Standard Replacement Pump. The delivery measure of this pump was only 'just' adiquate and gave rise to the sporadik inturuptions of the buzzer from doom when the oil was hot & the engine running at 2,500 rpm.

However, the build quality and gear meshing were good enough and had the buzzer not been working or annoying, I'm sure the engine would be fine. Would be a good fit to the earlier WBX Engines.

Then we looked at the Shardek Pumps. Two types, the standard & the higher delivery units. Both pumps were within very fine tollerences, perfect fitting & delivering faultlessly. The higher delivery unit sure got rid of the buzzer of doom syndrome, so that was a plus.... but (read about gaskets).

Lastly, we got our hands on a Mexican Pump Unisia. (standard delivery). The tollerences were (to us) totally unacceptable (big gaps in the gears and housing), so we rejected the pump without fitting. From the three manufacturers, this one was a definate no.

Then we went on to experiment with gaskets (those between the pump body and the cover plate). Shardek supplied the thinnest of these, but sealing the pump tight proved difficult, especially on the higher delivery unit. The slightly thicker gaskets were easier to seal. There is of course a pay back, the thicker the gasket, the more loss of pressure, but this (in our tests) proved to be very very little indeed. The tollerences in the gears & casing gaps seemed to be more crutial, so it's a bit of give and take. I'd rather go for the thicker gasket (within reason), than poor finish on the gears/case. If you go for the high volume pump, you can easily afford a slightly thicker cover gasket and be assured of 'no leaks'.

Finally, the Pump Cap (plate). We looked at three, one claimed to be VW, but was painted black on both sides, which meant, the paint would end up in the oil????, so we dumped that one.

The other two were basically engineered steel plates. The smoother one looked great, but wasn't so easy to seal.

The second was slightly more engineered in finish and sealed easily. The securing nuts have special rubber sealing rings and in the case of the high delivery units need tightening tighter than is recomended by VW.

An oil pump is the heart of an Engine. When it works, you wouldn't even know it was there and when it doesn't, you'll know!..... hope this helps someone, somewhere.

Mojoh.

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Oil Pressure Issues WBX

Painted cover plate can be brought back to steel with fine wet and dry

another pump to consider is this

https://www.vwheritage.com/shop/type25- ... StartRow=1" onclick="window.open(this.href);return false;

another pump to consider is this

https://www.vwheritage.com/shop/type25- ... StartRow=1" onclick="window.open(this.href);return false;

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

Re: Oil Pressure Issues WBX

Indeed, indeed, more options.

And end plates can be polished, nuts over tightened and oil pumps from all corners of the planet fitted.

For now, we are going to fit Shardek Pumps and original gaskets on high delivery units. If anyone comes across what they consider to be a top quality unit, we'd appreciate to hear about it here.

Have a great 80-90 day. Mojoh.

And end plates can be polished, nuts over tightened and oil pumps from all corners of the planet fitted.

For now, we are going to fit Shardek Pumps and original gaskets on high delivery units. If anyone comes across what they consider to be a top quality unit, we'd appreciate to hear about it here.

Have a great 80-90 day. Mojoh.

- ghost123uk

- Registered user

- Posts: 6855

- Joined: 10 Mar 2006, 10:15

- 80-90 Mem No: 2585

- Location: John in Malpas, in the very S. W. part of Cheshire.

- Contact:

Re: Oil Pressure Issues WBX

Indeeditchyfeet wrote:Welcome to 8090 whoever you are

would still love to know though - seems Aidan knows......

And again Paul, your pictures are awesome (that word used appropriately for a change

Got a new van, but it's a 165bhp T4 [shock horror] Accurate LPG Station map here

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Oil Pressure Issues WBX

Mojoh wrote:

Finally, the Pump Cap (plate)....

The other two were basically engineered steel plates.

I hear the Schadek pump with the pressed steel VW plate hits the late WBX carrier ( for late exhaust carriers) so this engineered plate may be interesting, do you have any details? is it just a flat plate?, I assume you fitted it to a late van because you were asking about the oil pressure switch, this was the reason I didn't fit one.

itchyfeet wrote:Painted cover plate can be brought back to steel with fine wet and dry

another pump to consider is this

https://www.vwheritage.com/shop/type25- ... StartRow=1" onclick="window.open(this.href);return false;

Although this says Brasilian I got delivered a Meyle pump when I ordered this which says it's German and I think generally accepted as a quality brand

I made a thin gasket from 0.07mm paper and used a little yellow dirko/head nut sealant to be sure, I also used standard nuts with the yellow sealant and it worked fine with the standard pump.

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

Re: Oil Pressure Issues WBX

Impressive that you 'make' a gasket. You knit jumpers too?. Seriously, this must have taken a long time. At about 50 quid an hour, that isn't going to work but I'm humbled in your goal for accuracy.

As for the oil pump covers, they are all the same as standard and yes, we have an issue with interferrence on the high volume pumps between cover and engine mounting cast plates... (the big lump of alloy that supports the engine).

The interferrence is slight, so we use 3 x 10mm thick flat washers to push the support back a fraction. I've got photo's of all this stuff but haven't worked out how to upload them here.

As for the oil pump covers, they are all the same as standard and yes, we have an issue with interferrence on the high volume pumps between cover and engine mounting cast plates... (the big lump of alloy that supports the engine).

The interferrence is slight, so we use 3 x 10mm thick flat washers to push the support back a fraction. I've got photo's of all this stuff but haven't worked out how to upload them here.

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Oil Pressure Issues WBX

I don't bill myself for my time spent  takes 5 minuites with a scaplel draw around a gasket.

takes 5 minuites with a scaplel draw around a gasket.

if you are passionate about WBX and do enough you could have them made ( and then sell them to us lot)

what's knitting?

photos = photobucket then use [IMG] link

if you are passionate about WBX and do enough you could have them made ( and then sell them to us lot)

what's knitting?

photos = photobucket then use [IMG] link

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

Re: Oil Pressure Issues WBX

OK, thanks for the info on Photo-bucket. I take it it's an app?

I'll check it out.

M

I'll check it out.

M

- itchyfeet

- Registered user

- Posts: 12425

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Oil Pressure Issues WBX

There is an app for phones and tablets yes but phototobucket is a well known photo hosting website no app needed from a pc, upload your pics and you can then post links to them in forums like this so they then appear in the forum but are stored on the photobucket website, there is no photo storage on here.

http://photobucket.com/" onclick="window.open(this.href);return false;

click on any of my photos above and it takes you to my photobucket location

http://photobucket.com/" onclick="window.open(this.href);return false;

click on any of my photos above and it takes you to my photobucket location

1988 DG WBX LPG Tin Top

itchylinks

itchylinks

Re: Oil Pressure Issues WBX

Update on this issue.

We've settled on Shardek high delivery pumps for the later WBX blocks. Using the thinner gaskets for the cover plates. For the earlier wbx blocks, DF and DG we will use the standard delivery units.

As for oil pressure switches, blue for the low pressure bank, grey for the high pressure bank and crossed fingures.

Oil, still recommending mineral oil, 15w-40 ish......

Change it every 3000 miles, filter every 6000, then you can't really go wrong. Keep it well topped up, plus a half litre. The oil pan (so to speak) is larger than you imagine, so no worries there! High is better than low for sure.....

Mj

We've settled on Shardek high delivery pumps for the later WBX blocks. Using the thinner gaskets for the cover plates. For the earlier wbx blocks, DF and DG we will use the standard delivery units.

As for oil pressure switches, blue for the low pressure bank, grey for the high pressure bank and crossed fingures.

Oil, still recommending mineral oil, 15w-40 ish......

Change it every 3000 miles, filter every 6000, then you can't really go wrong. Keep it well topped up, plus a half litre. The oil pan (so to speak) is larger than you imagine, so no worries there! High is better than low for sure.....

Mj