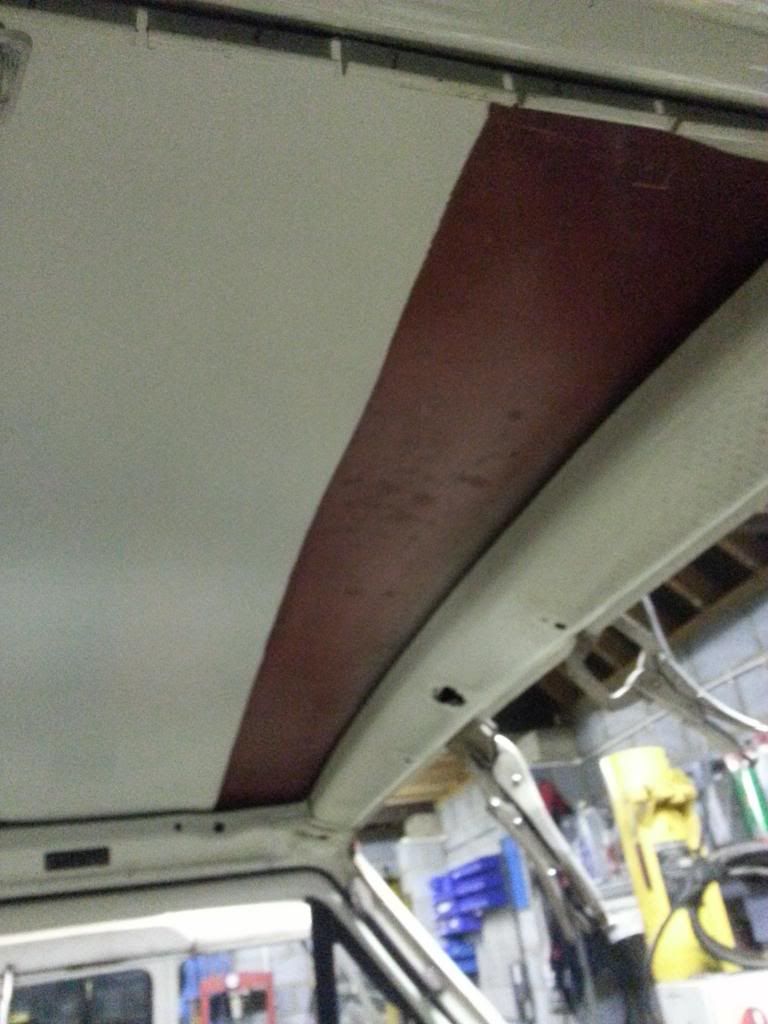

One of the challenges in fixing the roof is maintaining the shape of the "bow" in the roof. Now I know it will never be seen under the high top but I wanted to see how close I could get it. Really needed one of those extending plasterers aids but haven't got one of those so press ganged a transmission jack into use

Then puddle welded starting at the edges and doing 1 in every 3 to try and keep the lines as straight as possible.

Not a bad result, Mig brazed in the corners and tidied up and then finished the windscreen surround.

Then finished off the edges, the braze comes up as looking like rust on the camera for some reason, it looks better in real life :0

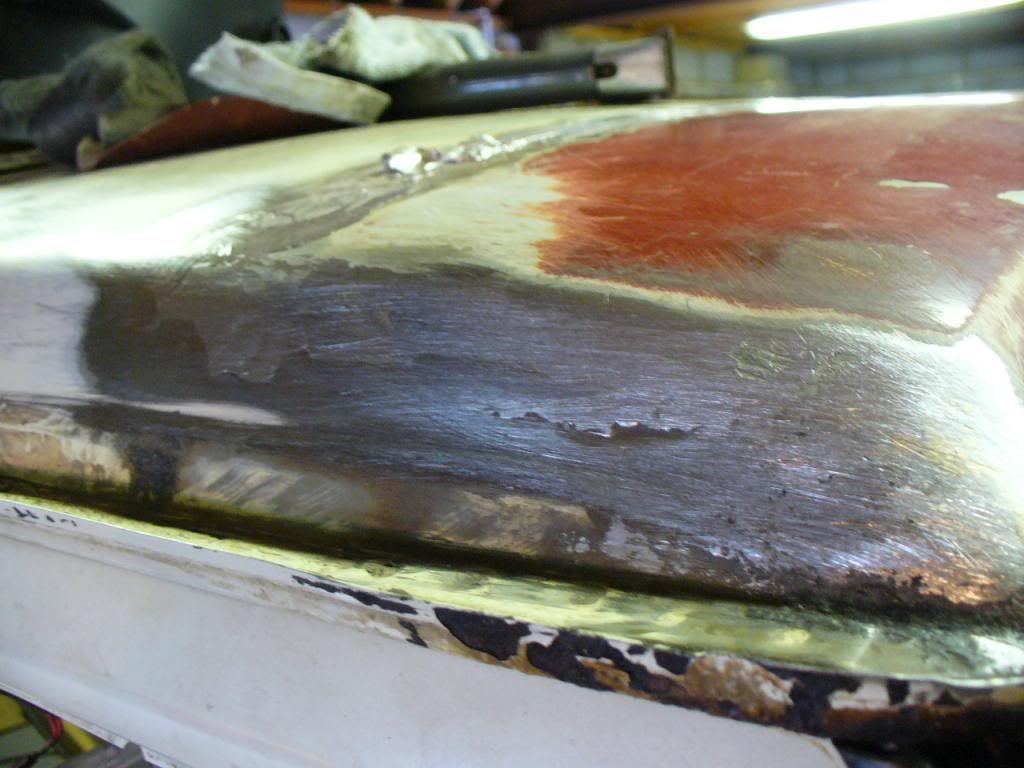

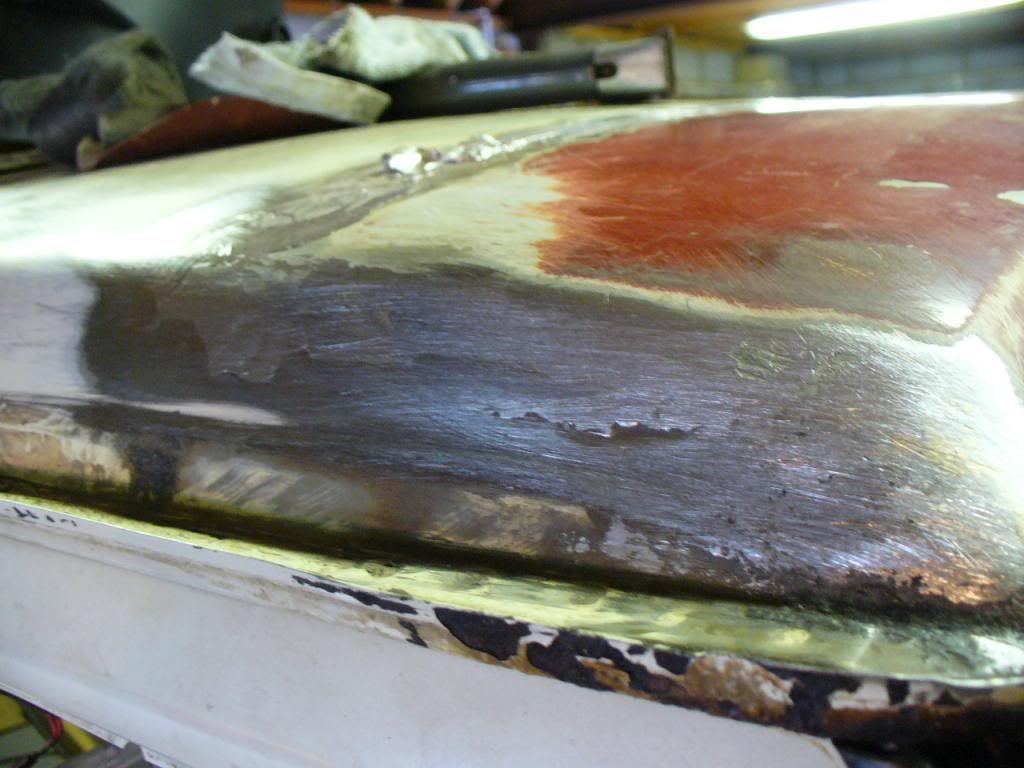

Next job was to lead in (body solder) the edges and the roof join. Again the roof doesn't really need it as it will be under the hightop but I wanted a bit of practice at leading anyway as I had struggled last time.

First attempt was a mess, couldn't bear to take any pics

something wasn't right.

So after many e-mails with Mike and going back to basics I decided to check the lead sticks I had been supplied. This is what one looks like BTW

So, quick lesson is body solder.......body solder sticks are usually 70:30 lead:tin or some use 60:40, so when you buy a "60:40" it is usually 60% lead. This is important as it affects the melting point and workability of the solder. Turns out that Solder Connection when they quote 60:40 mean 60% Tin. When you read there tech materials there "20 years experience of supplying materials for the auto trade" leads them to supply a "60:40" for horizontal panels and a "23:73" i.e. 73% lead for vertical panels. Why do they supply a different mix for vertical panels? Well the high tin content in their 60:40 means you only have a 5 degree window in which the solder becomes "plastic" i.e. workable as opposed to a 20 - 30 degree window with 70:30.

So guess what? When you heat it you can't control to within 5 degrees so you either have solid or liquid and nothing in between, makes it impossible to work with

or at least it does for me - not seen anyone using 60:40 with only 40% lead anywhere else but stand to be corrected?

To check my theory I melted down a couple of sticks and added a few old lead fishing weights to boost the lead content and, hey presto, perfect results.

Slapped some on the offside join

Then filed it down. Still got a couple of low points to fill but looking really nice now - its all a learning experience!

From this......

To this......

Then ran out of gas for the heat gun

Cheers,

MM