1Y engine conversion

Moderators: User administrators, Moderators

Re: 1Y engine conversion

Quick question if anyone reading this can help. Are all 1Y engines the same? I am looking at getting a 1.9d 1Y from a Seat Ibiza, will this thread apply to my conversion? Thanks, Jon. And good luck Blue67

1982 Diesel hightop. 1Y engine. Still work in progress but running and taking us on holidays.

Re: 1Y engine conversion

Jonnyb416 wrote:Quick question if anyone reading this can help. Are all 1Y engines the same? I am looking at getting a 1.9d 1Y from a Seat Ibiza, will this thread apply to my conversion? Thanks, Jon. And good luck Blue67

This is the engine in my van and I've always found this thread very helpful.

-

blue67

- Registered user

- Posts: 68

- Joined: 26 Jan 2009, 17:02

- 80-90 Mem No: 6646

- Location: Clowne, Chesterfield

- Contact:

Re: 1Y engine conversion

Jonnyb416 wrote:Quick question if anyone reading this can help. Are all 1Y engines the same? I am looking at getting a 1.9d 1Y from a Seat Ibiza, will this thread apply to my conversion? Thanks, Jon. And good luck Blue67

All pretty much the same mate, just fitted to different stuff. Let us know how u get on

-

blue67

- Registered user

- Posts: 68

- Joined: 26 Jan 2009, 17:02

- 80-90 Mem No: 6646

- Location: Clowne, Chesterfield

- Contact:

Re: 1Y engine conversion

Just an update, still not got this running and it is blooming cold outside! and i have turned into a softy

When it warms up a bit I intend on checking all the timing marks again and double checking the cam posion, as i may have timed it TDC on No.4 instead of No.1. Also have been told about unbolting the pump slightly and sliding it one way or another to adjust the fueling, although i dont really wanna do that, as i feel i will be cocking up summat i dont fully understand!

TTFN

When it warms up a bit I intend on checking all the timing marks again and double checking the cam posion, as i may have timed it TDC on No.4 instead of No.1. Also have been told about unbolting the pump slightly and sliding it one way or another to adjust the fueling, although i dont really wanna do that, as i feel i will be cocking up summat i dont fully understand!

TTFN

-

The G

- Registered user

- Posts: 6

- Joined: 15 May 2008, 07:31

- 80-90 Mem No: 5290

- Location: Bridgwater,somerset

Re: 1Y engine conversion

Hi Guys,

I've been running with a 1y lump in by bus for the best part of two years and apart from a few teething problems all is well and well worth the change.

HOWEVER.. When I did the conversion I bought a new starter motor for it because the old one was temperamental, When installing the new one I had to angle the starter by 2mm to get the teeth to mesh properly.. weired until a fellow mechanic suggested that the 1y crank may sit slightly higher than the old engine, but then I asked surly it wouldn't sit on the gearbox splines properly he replied 2mm isn't that much Hmmm. Any way a slight mod (HALF A TWO MM WASHER IN THE TOP THEN TIGHTEN IT HOME TO THE BELL HOUSING) and it works however I'm now thinking maybe the original flywheel that came with the 1Y is slightly larger than the one from the old engine ( CAN ANY ONE CONFIRM THE REASON FOR USING THE OLD CLUCH AND FLYWHEEL) but the the old clutch plates and stuff fit OK (1y never came with a clutch just flywheel). any way I have no problems with it until this afternoon when I tried to start it All i can hear is a very positive clunk of the solenoid engaging but nothing from the motor ????

It's only two years old, bats only 6 months old and fully charged.

Any suggestions

I've been running with a 1y lump in by bus for the best part of two years and apart from a few teething problems all is well and well worth the change.

HOWEVER.. When I did the conversion I bought a new starter motor for it because the old one was temperamental, When installing the new one I had to angle the starter by 2mm to get the teeth to mesh properly.. weired until a fellow mechanic suggested that the 1y crank may sit slightly higher than the old engine, but then I asked surly it wouldn't sit on the gearbox splines properly he replied 2mm isn't that much Hmmm. Any way a slight mod (HALF A TWO MM WASHER IN THE TOP THEN TIGHTEN IT HOME TO THE BELL HOUSING) and it works however I'm now thinking maybe the original flywheel that came with the 1Y is slightly larger than the one from the old engine ( CAN ANY ONE CONFIRM THE REASON FOR USING THE OLD CLUCH AND FLYWHEEL) but the the old clutch plates and stuff fit OK (1y never came with a clutch just flywheel). any way I have no problems with it until this afternoon when I tried to start it All i can hear is a very positive clunk of the solenoid engaging but nothing from the motor ????

It's only two years old, bats only 6 months old and fully charged.

Any suggestions

5290 - Keeping it real

Re: 1Y engine conversion

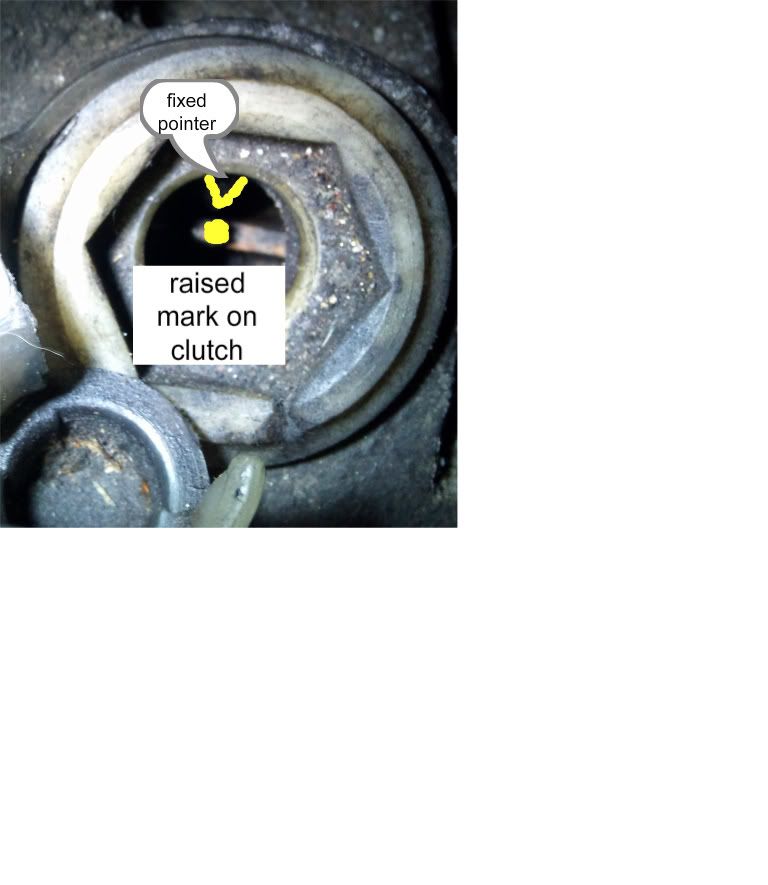

You are supposed to use the clutch and flywheel. The starter motor fits as it should with this setup. Plus you can use the mark on the clutch to set the timing up properly.

I think you have done well having your starter last this long!

Unless of course I have misunderstood?

Ringo

I think you have done well having your starter last this long!

Unless of course I have misunderstood?

Ringo

Now driving a big bad VW LT Florida.

-

blue67

- Registered user

- Posts: 68

- Joined: 26 Jan 2009, 17:02

- 80-90 Mem No: 6646

- Location: Clowne, Chesterfield

- Contact:

Re: 1Y engine conversion

Its warming up a bit now so time to start sorting this mess out!!

I have checke the cam position, the crank position and the fuel pump position and i am happy that it is timed to No1 TDC, the fuel pump hole lines up as does the marker on the fly wheel, it is all perfect, i have installed a replacement fuel pipe from the filter head with a primer bulb and have pumped until fuel emerges from the return fuel line. I have doudle checked the fuel shut off valve and that "clicks" nicely with the ignition switch. And yet some how this lump will not fire!!! all i get is turning over with smoke from the exhaust, then for a few seconds it catches, revs up and dies, with a cloud of smoke.

Now my thoughts are either:

but one thing is for sure i am fast running out of love for my van and need some help please!!

All suggestions and any help to get this dam thing working will be greatly received!

just for reference i have some photos of the timing position, although i forgot to take a photo of the fuel pump position:

I have checke the cam position, the crank position and the fuel pump position and i am happy that it is timed to No1 TDC, the fuel pump hole lines up as does the marker on the fly wheel, it is all perfect, i have installed a replacement fuel pipe from the filter head with a primer bulb and have pumped until fuel emerges from the return fuel line. I have doudle checked the fuel shut off valve and that "clicks" nicely with the ignition switch. And yet some how this lump will not fire!!! all i get is turning over with smoke from the exhaust, then for a few seconds it catches, revs up and dies, with a cloud of smoke.

Now my thoughts are either:

- i have made a fundemental mistake installing this

- i have a duff engine

- there is a problem with the fuel pump

but one thing is for sure i am fast running out of love for my van and need some help please!!

All suggestions and any help to get this dam thing working will be greatly received!

just for reference i have some photos of the timing position, although i forgot to take a photo of the fuel pump position:

-

camper

- Registered user

- Posts: 357

- Joined: 30 Oct 2005, 20:26

- 80-90 Mem No: 1710

- Location: Bookham Surrey

Re: 1Y engine conversion

Looking at the tdc position on the flywheel in the pict dont look convincing .If you fit the the 1.6n/td flywheel &clutch there is a V mark cut for tdc

-

blue67

- Registered user

- Posts: 68

- Joined: 26 Jan 2009, 17:02

- 80-90 Mem No: 6646

- Location: Clowne, Chesterfield

- Contact:

Re: 1Y engine conversion

yeah used the 1.6na fly wheel and clutch, there is a fixed poiner which lines up with a raised mark, i have tried as best i can to photo that. what your saying is that i have timed it up using the wrong mark on the crank?camper wrote:Looking at the tdc position on the flywheel in the pict dont look convincing .If you fit the the 1.6n/td flywheel &clutch there is a V mark cut for tdc

-

camper

- Registered user

- Posts: 357

- Joined: 30 Oct 2005, 20:26

- 80-90 Mem No: 1710

- Location: Bookham Surrey

Re: 1Y engine conversion

I you used a 1.6/td flywheel&clutch turn untill you find a V cut mark then line up to the pointer.

-

peteabbott

- Registered user

- Posts: 332

- Joined: 24 Jan 2008, 17:40

- 80-90 Mem No: 4672

- Location: Ipswich

Re: 1Y engine conversion

To be sure of No.1 TDC remove the injector from No.4 (TDC same time as No.1) as No.4 is easier to remove. You can then insert a piece of soft wire into the hole and Feel TDC as the piston rises and falls. Where is your TDC mark that you are using now ? If it is different then the piece of soft inserted wire does not lie. Still time it on No.1 as you have been. Hope I havn,t confused things but keep at it.you are nearly there. Good luck, summer is coming.

Pete Abbott

-

blue67

- Registered user

- Posts: 68

- Joined: 26 Jan 2009, 17:02

- 80-90 Mem No: 6646

- Location: Clowne, Chesterfield

- Contact:

Re: 1Y engine conversion

there has been a little development with this at last,

i have now found the correct timing marks and set the timing so everything is correct, needs checking tho as the same symptoms exsist exceot the engin runs for a little longer and fires a little easier. still not fixed it tho!!

will need to recheck the timing again......

i have now found the correct timing marks and set the timing so everything is correct, needs checking tho as the same symptoms exsist exceot the engin runs for a little longer and fires a little easier. still not fixed it tho!!

will need to recheck the timing again......

-

blue67

- Registered user

- Posts: 68

- Joined: 26 Jan 2009, 17:02

- 80-90 Mem No: 6646

- Location: Clowne, Chesterfield

- Contact:

Re: 1Y engine conversion

We are all timed up proper and it has been checked by a local garage, who have susggested that the pump is at fault, the engine starts and runs but is unresposive to the throttle, I am unsure if the pump has failed or if it isnt bled properly. Can anyone suggest anything to end this misery? I must be close to getting it running. Please help ..........

-

colinthefox

- Registered user

- Posts: 923

- Joined: 20 Oct 2009, 18:42

- 80-90 Mem No: 16447

- Location: Somerset

- Contact:

Re: 1Y engine conversion

So your engine is running, and will run continuously, but won't respond to the throttle. You have fitted a priming bulb. Do I understand correctly? I have assumed that you have indeed got it all timed correctly now.

If the engine runs continuously, then it has been bled of air, or it wouldn't run at all. Once running, it will clear itself of air quickly providing there are no massive leaks.

As I explained earlier in this thread, the injection pump consists of two pumps really, a lift pump and a high pressure injection pump. The high pressure section appears to be working to an extent, or it wouldn't fire at all. Has the throttle lever been removed at any stage? If so it may not have been replaced correctly. Have the pump adjustments been disturbed?

So why might the lift pump not be working properly?

Could be a large air leak on the suction side, so the lift pump supplies the injection pump with an air/fuel mix.

Could be (as mentioned previously) that the inlet and outlet banjos have been fitted wrong. The return one has an internal restrictor designed to build up some pressure in the pump. If it has been fitted on the supply side you will be restricting the fuel supply.

Could be the lift pump not working well. It has been suggested by others (although I've never come across it) that if the pump had got water in it while removed from the donor then the vanes in the lift pump tend to stick. I suppose you could check this by pumping the priming bulb to assist the lift pump with the engine running.

Final suggestion here is that if the pump had been standing it may be full of gunge. The pump on my tractor was full of gunge when I got it, and would only idle.

If the lift pump isn't functioning correctly, then it's a rebuild at your local diesel specialist I'm afraid.

Most diesels are a little smoky for a few minutes when starting from scratch after downtime. Last time I had one that was very smoky and didn't want to accelerate, I had left a rag in the air inlet. DOH!

No magic solutions here, but I hope there is something that will help.

If the engine runs continuously, then it has been bled of air, or it wouldn't run at all. Once running, it will clear itself of air quickly providing there are no massive leaks.

As I explained earlier in this thread, the injection pump consists of two pumps really, a lift pump and a high pressure injection pump. The high pressure section appears to be working to an extent, or it wouldn't fire at all. Has the throttle lever been removed at any stage? If so it may not have been replaced correctly. Have the pump adjustments been disturbed?

So why might the lift pump not be working properly?

Could be a large air leak on the suction side, so the lift pump supplies the injection pump with an air/fuel mix.

Could be (as mentioned previously) that the inlet and outlet banjos have been fitted wrong. The return one has an internal restrictor designed to build up some pressure in the pump. If it has been fitted on the supply side you will be restricting the fuel supply.

Could be the lift pump not working well. It has been suggested by others (although I've never come across it) that if the pump had got water in it while removed from the donor then the vanes in the lift pump tend to stick. I suppose you could check this by pumping the priming bulb to assist the lift pump with the engine running.

Final suggestion here is that if the pump had been standing it may be full of gunge. The pump on my tractor was full of gunge when I got it, and would only idle.

If the lift pump isn't functioning correctly, then it's a rebuild at your local diesel specialist I'm afraid.

Most diesels are a little smoky for a few minutes when starting from scratch after downtime. Last time I had one that was very smoky and didn't want to accelerate, I had left a rag in the air inlet. DOH!

No magic solutions here, but I hope there is something that will help.

1.9D (AEF) pop-top. Aaaaahhhhh........that's better.

- weldore

- Registered user

- Posts: 5595

- Joined: 17 Aug 2008, 22:36

- 80-90 Mem No: 5833

- Location: North Notts

Re: 1Y engine conversion

I would go with the spindle that the lever sits on needs adjusting

the word 'pissing' is safe

Dave and gail.....1983 Pop Top 1.9n/a diesel (aka Ready Steady Eddie)

Dave and gail.....1983 Pop Top 1.9n/a diesel (aka Ready Steady Eddie)