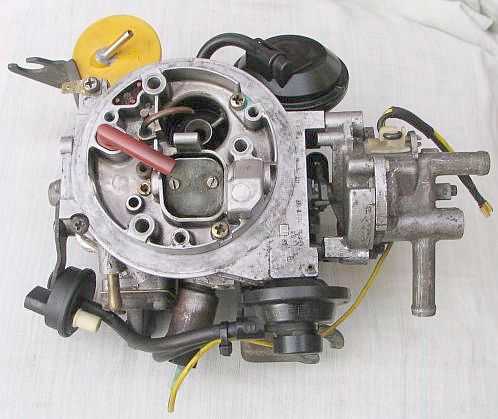

Automatic choke..

This is the Pierburg 2E3′s Achilles heel. It has a choke mechanism that has always been misunderstood but this is the theory;

A choke is meant to actually ‘choke’ or starve the carburetor of air when the engine is cold so that the richer mixture is ignited easier. As the engine warms up a bi-metallic strip uncoils as it senses the increasing engine temperature. This sensing of engine temperature happens with the help of coolant that is ran through part of the carburetor’s choke mechanism. The choke works hand in hand with a mechanism called fast idle cam that if well set, keeps idle speed high and reduces it with increasing engine temperature. There is an additional component that helps heat up the bi-metallic strip using electrical energy from the battery. This usually helps open up the choke faster than the water would. Though in warmer climates it's no use.

The aim is to set the choke (butterfly) gap such that when the engine is at its coldest it leaves a gap along the barrel that is only small enough to accommodate a 3mm drill-bit and the fast idle cam can cause idle speed to rise to 2000 +/- 200 rpm.

Remove the choke body to reveal the bi-metallic strip/spring thingy

Open the throttle and position the fast idle cam screw on the highest step of the cam by turning it

Push the pullrod on the choke pull-down unit the furthest it could go and check the gap left when the bi-metallic strip is turned to the ‘start’ position. Turn the screw that manages the pullrod in or out accordingly until pushing the pullrod furthest in will lead to a 3mm gap between the choke butterfly plate and the barrel, when the bi-metallic strip is turned to its ‘start’ position.

Refit the choke body ensuring that it remains on the ‘start’ position when coldest.The position of the choke body can always be adjusted depending on seasons so that there is always optimum cold start engine speeds

Fast idle should also be adjusted hand in hand with the choke pull-down diaphragm but when the engine is warm and at normal operating temperature.

Position the fast idle cam screw by turning it in or out to the second step of the fast idle cam and check that the fast idle speed is between the specified 2000 +/- 200 rpm for fast idle. Adjust as neccessary

however all this is pointess if you have an air leak on the inlet side of the engine

AGG 2.0L 8V. (Golf GTi MkIII)