1.6td to Volvo b230a...

Moderators: User administrators, Moderators

- axeman

- Registered user

- Posts: 1256

- Joined: 07 Feb 2009, 19:50

- 80-90 Mem No: 6410

- Location: Smeeth kent country side

Re: 1.6td to Volvo b230a...

it's a bit crude for my liking but this guy has moded his engine hatch. in his velle.

http://vwkd.co.uk/bb/viewtopic.php?t=35 ... ight=volvo" onclick="window.open(this.href);return false;

any how i how is every thing going tom any more progress?

neil

http://vwkd.co.uk/bb/viewtopic.php?t=35 ... ight=volvo" onclick="window.open(this.href);return false;

any how i how is every thing going tom any more progress?

neil

Back in the game with an uncut 2wd panel van

-

jed the spread

- Trader

- Posts: 9020

- Joined: 09 Oct 2005, 17:31

- 80-90 Mem No: 1967

- Location: Sutton in'it Syncronaut: 123

- Contact:

Re: 1.6td to Volvo b230a...

EEK!!!!! just as I thought  Thats got to be 6" sticking out of the top..... Doesnt really fit in does it.

Thats got to be 6" sticking out of the top..... Doesnt really fit in does it.

jed

jed

-

silverbullet

- Trader

- Posts: 17294

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: 1.6td to Volvo b230a...

It's all gone a bit quiet from the OP on this one...

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

Hello everyone

Things have slowed up a bit. I am waiting for funds to be released then I can start work again. I didn't want to swamp the post with resto talk.

I have carried out a little resto work underneath the van where the fuel tank, engine and gearbox sit. Couple of coats of hammerite done, just a coat of waxoil to go.

I am in the process of taking the drive shafts off. I am planning on changing the CV joints for 4 fat boys from Baxters. I have bought a number of parts including clutch, braided clutch line and repair kit.

Got to get more bits and I still havn't sorted my CARB. I have been given a number to try hopefully I can get it sorted.

Coolant pipes and connections plus final design and manufacture of s/s pipes.

Clutch cable..speedy cables has many options..have to contact them.

Bolts for flywheel and clutch.

Lubricants

Exhaust system.

Fuel lines for new tank plus breather hoses/pipes etc

Need to work out wiring and conections..what I can and can't use etc. Water and Oil temp/pressure

Vacuum connection pipe for the brakes.

Engine mounts and supports still to buy.

I have with the help of a Volvo dealer compiled a list parts including Oil crank seals rear and front...I have decided to change them and the engine is stripped (again) waiting for the replacements..when I can afford them. (Not doing the cam shaft seal..bolt was a bit tight for me). I am going to buy two blanking plugs for the EGR connections.

I have borrowed a tool from work to take the rear crankcase spigot bearing out. Should be interesting getting it out.

Plenty to do and I have work again on Sat...I will keep you posted when things develop further....

Thanks for looking and the support...

Tom

Oh..I almost forgot...not particularly worried about the engine height and where it sits...leave that topic for another day I think..

Things have slowed up a bit. I am waiting for funds to be released then I can start work again. I didn't want to swamp the post with resto talk.

I have carried out a little resto work underneath the van where the fuel tank, engine and gearbox sit. Couple of coats of hammerite done, just a coat of waxoil to go.

I am in the process of taking the drive shafts off. I am planning on changing the CV joints for 4 fat boys from Baxters. I have bought a number of parts including clutch, braided clutch line and repair kit.

Got to get more bits and I still havn't sorted my CARB. I have been given a number to try hopefully I can get it sorted.

Coolant pipes and connections plus final design and manufacture of s/s pipes.

Clutch cable..speedy cables has many options..have to contact them.

Bolts for flywheel and clutch.

Lubricants

Exhaust system.

Fuel lines for new tank plus breather hoses/pipes etc

Need to work out wiring and conections..what I can and can't use etc. Water and Oil temp/pressure

Vacuum connection pipe for the brakes.

Engine mounts and supports still to buy.

I have with the help of a Volvo dealer compiled a list parts including Oil crank seals rear and front...I have decided to change them and the engine is stripped (again) waiting for the replacements..when I can afford them. (Not doing the cam shaft seal..bolt was a bit tight for me). I am going to buy two blanking plugs for the EGR connections.

I have borrowed a tool from work to take the rear crankcase spigot bearing out. Should be interesting getting it out.

Plenty to do and I have work again on Sat...I will keep you posted when things develop further....

Thanks for looking and the support...

Tom

Oh..I almost forgot...not particularly worried about the engine height and where it sits...leave that topic for another day I think..

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

Hello everyone..

Been doing a few little jobs while waiting for my much needed funds to be released. Once they are available the project out to gather pace.

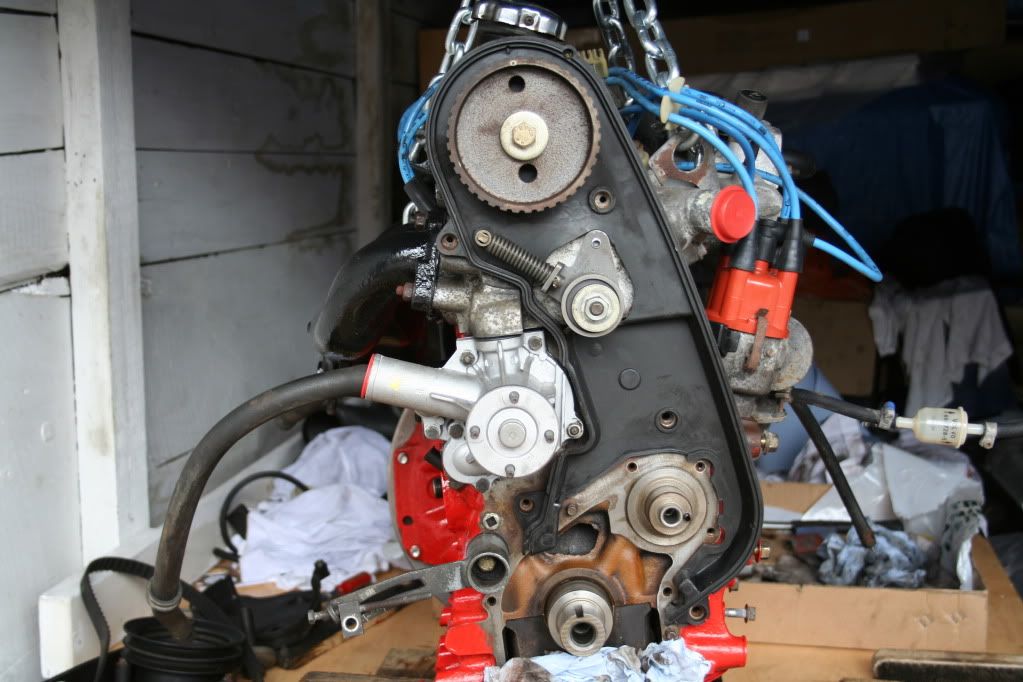

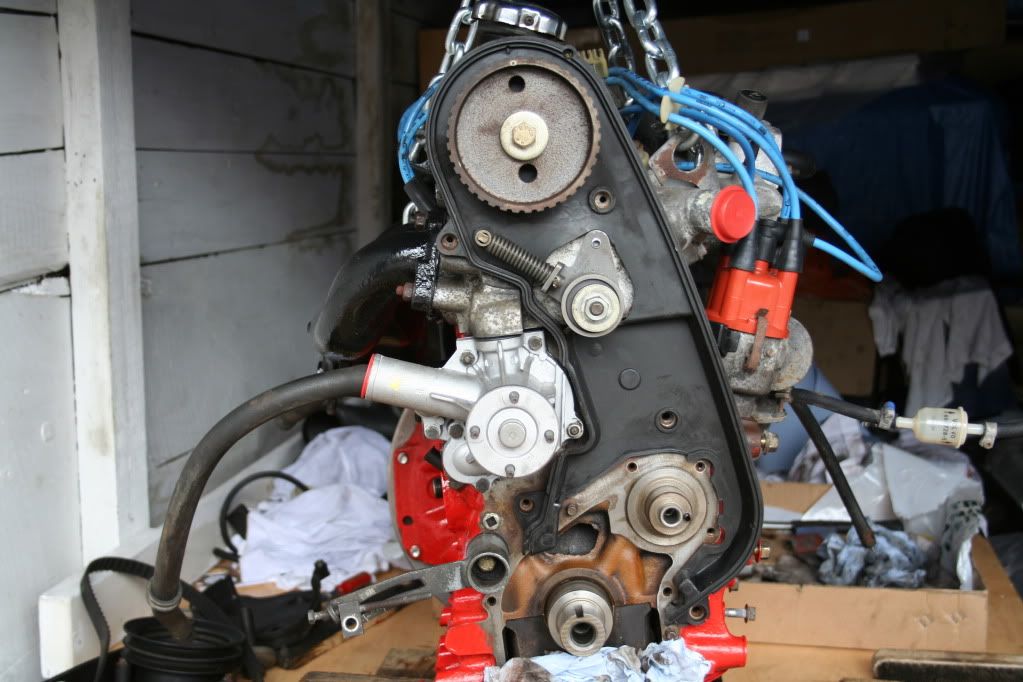

After reading Neil's reply I prepared the engine ready for new oil seals. Stripping back the engine again was probably a good idea. I didn't feel happy about ignoring the dirty oil seal hidden behind the intermediate sprocket. Here are some flicks of the front and rear of the engine.

A closer peek

The offending seal that bugged me

Ready and waiting for new....

A flick of the rear seal removed

scraps and flange seal faces

I then worked on removing the spigot bearing. I borrowed a tool from work...handy piece of kit too..

Exposed the inner racing and got to work..I set up the puller and screwed on the sliding hammer...out it came...

A new one was then fitted..job done.

I took my flywheel to work and had 4 holes drilled and filled with weld. I had the holes drilled such that the starter ring gear was exposed..enable the weld to bite both surfaces.

The measurements are equal..one question asked was the risk of the flywheel being unballanced because of both heat exposer and filled spot "loads". On the other hand it has been siad because of the flywheels thickness it out not to be affected. If there is any rotational distortion I will more than likely feel it on changing/depressing the clutch..I am going to take a chance on how it is...The chap that did it for me only drilled 4mm into the face. Looks solid and I would like to thank Ian (Silverbullet) for that advice. Take a look at the weld points....

Here is a flick of some goodies I bought from Brickwerks..I ran out of funds at this point...a tidy sum all together.. the new fuel tank was part of the buy, another splendid purchase..

228mm clutch kit..just fitting bolts to get..need to source them plus the size needed. Still havn't worked out the size of bolts needed for the fly wheel..M10's..just the right length and strength...I don't know if you can remember Neil..

New braided clutch pipe and repair kit..plus a few connectors to help me renew mot of the clutch line. I am presuming the swivel end on the braided line is fitted to the clutch slave cylinder. Took about 3 weeks to come from Brickwerks..I received two window stickers and a note apologising for the delay...

Bought new cv boots x4 and 4 chunky Porsche cv joints...The plan here was to prepare the rear drive for a torque engine and towing.

I got to work on the drive shafts and it was an interesting job...never done it before..I am glad that I have renewed them..the ones I took off had served their purpose and looked liked they where ready for replacement.

Out with the old and in with the new....nice.. well chuffed..

well chuffed..

Thats it for the time being....I have a few calls to make about things I need as I mentioned on my last post. I am still waiting on Speedy cables..I have asked about the choke cable..yet to hear...I need to catch up with Neil, seems a life time since we had a chat..I shall start my list. Off work now till Sunday....Two more banks of work and I have another 18 days...hopefully I will be fully ready and prepared for a good push on the project...

Thanks for looking..

Tom

Been doing a few little jobs while waiting for my much needed funds to be released. Once they are available the project out to gather pace.

After reading Neil's reply I prepared the engine ready for new oil seals. Stripping back the engine again was probably a good idea. I didn't feel happy about ignoring the dirty oil seal hidden behind the intermediate sprocket. Here are some flicks of the front and rear of the engine.

A closer peek

The offending seal that bugged me

Ready and waiting for new....

A flick of the rear seal removed

scraps and flange seal faces

I then worked on removing the spigot bearing. I borrowed a tool from work...handy piece of kit too..

Exposed the inner racing and got to work..I set up the puller and screwed on the sliding hammer...out it came...

A new one was then fitted..job done.

I took my flywheel to work and had 4 holes drilled and filled with weld. I had the holes drilled such that the starter ring gear was exposed..enable the weld to bite both surfaces.

The measurements are equal..one question asked was the risk of the flywheel being unballanced because of both heat exposer and filled spot "loads". On the other hand it has been siad because of the flywheels thickness it out not to be affected. If there is any rotational distortion I will more than likely feel it on changing/depressing the clutch..I am going to take a chance on how it is...The chap that did it for me only drilled 4mm into the face. Looks solid and I would like to thank Ian (Silverbullet) for that advice. Take a look at the weld points....

Here is a flick of some goodies I bought from Brickwerks..I ran out of funds at this point...a tidy sum all together.. the new fuel tank was part of the buy, another splendid purchase..

228mm clutch kit..just fitting bolts to get..need to source them plus the size needed. Still havn't worked out the size of bolts needed for the fly wheel..M10's..just the right length and strength...I don't know if you can remember Neil..

New braided clutch pipe and repair kit..plus a few connectors to help me renew mot of the clutch line. I am presuming the swivel end on the braided line is fitted to the clutch slave cylinder. Took about 3 weeks to come from Brickwerks..I received two window stickers and a note apologising for the delay...

Bought new cv boots x4 and 4 chunky Porsche cv joints...The plan here was to prepare the rear drive for a torque engine and towing.

I got to work on the drive shafts and it was an interesting job...never done it before..I am glad that I have renewed them..the ones I took off had served their purpose and looked liked they where ready for replacement.

Out with the old and in with the new....nice..

Thats it for the time being....I have a few calls to make about things I need as I mentioned on my last post. I am still waiting on Speedy cables..I have asked about the choke cable..yet to hear...I need to catch up with Neil, seems a life time since we had a chat..I shall start my list. Off work now till Sunday....Two more banks of work and I have another 18 days...hopefully I will be fully ready and prepared for a good push on the project...

Thanks for looking..

Tom

-

silverbullet

- Trader

- Posts: 17294

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: 1.6td to Volvo b230a...

I don't remember thatcarpmaster wrote:I took my flywheel to work and had 4 holes drilled and filled with weld. I had the holes drilled such that the starter ring gear was exposed..enable the weld to bite both surfaces.

The measurements are equal..one question asked was the risk of the flywheel being unballanced because of both heat exposer and filled spot "loads". On the other hand it has been siad because of the flywheels thickness it out not to be affected. If there is any rotational distortion I will more than likely feel it on changing/depressing the clutch..I am going to take a chance on how it is...The chap that did it for me only drilled 4mm into the face. Looks solid and I would like to thank Ian (Silverbullet) for that advice.

But that means getting the flywheel balanced on the crankshaft being used, along with the front pulley and clutch cover, to do the job properly.

Last edited by silverbullet on 04 Jul 2011, 21:42, edited 1 time in total.

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

I don't remember thatsilverbullet wrote:[quote="carpmaster]I took my flywheel to work and had 4 holes drilled and filled with weld. I had the holes drilled such that the starter ring gear was exposed..enable the weld to bite both surfaces.

The measurements are equal..one question asked was the risk of the flywheel being unballanced because of both heat exposer and filled spot "loads". On the other hand it has been siad because of the flywheels thickness it out not to be affected. If there is any rotational distortion I will more than likely feel it on changing/depressing the clutch..I am going to take a chance on how it is...The chap that did it for me only drilled 4mm into the face. Looks solid and I would like to thank Ian (Silverbullet) for that advice.

But that means getting the flywheel balanced on the crankshaft being used, along with the front pulley and clutch cover, to do the job properly.[/quote][/quote]

Sorry Ian, I owe you an apology..I got my wires mixed you didn't discuss it with me. I was pretty tired when I posted..I wanted to thank you for something completly different.

I will give you a buzz about the engine supports...

Tom

-

silverbullet

- Trader

- Posts: 17294

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: 1.6td to Volvo b230a...

No worries! Just checking. Wouldn't want to get mis-quoted, not with my patchy reputation

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

Hello again..

Thanks for looking at my post..

I have been pottering around with the engine over the last few days. I received the parts I needed to finish off and got to work on the crank seals. I am also spending time buying pieces still needed to finish the job. The shopping list is getting smaller there are just a few parts left to get. Here are a few photos ..

..

A flick of the seals and gaskets. I had to buy a new rear crank sealing flange. The old one had hair line fractures in it..better to play safe. I spotted a crank breather on ebay and snapped it up for a fair price. I will soak the old one in petrol to clean it off(Thanks Neil) and have it as a "quick service" replacement spare.

You will also notice a carb in the flick..I landed on my feet with this, I have been looking for nearly two months trying to source a spare. Why! you might ask...I want to learn everything about how a carb works and at the same time overhaul it. The one I bought is exactly the same make as my current one. I gave it a clean and its come up lovely. What I didn't do was open it up and mess around. I plan to use as is and work on the other in my spare time.

The header tank from a mrk4 golf is also shown. I have yet to buy the coolant pipes and associated parts.

Here are a few photos ..

..

The front seals before and after

The back end..before, showing a new spigot bearing

Finished look with new seal & sealing flange...Thanks Neil for the part numbers for the gasket and seal.

Thanks for looking at my post..

I have been pottering around with the engine over the last few days. I received the parts I needed to finish off and got to work on the crank seals. I am also spending time buying pieces still needed to finish the job. The shopping list is getting smaller there are just a few parts left to get. Here are a few photos

A flick of the seals and gaskets. I had to buy a new rear crank sealing flange. The old one had hair line fractures in it..better to play safe. I spotted a crank breather on ebay and snapped it up for a fair price. I will soak the old one in petrol to clean it off(Thanks Neil) and have it as a "quick service" replacement spare.

You will also notice a carb in the flick..I landed on my feet with this, I have been looking for nearly two months trying to source a spare. Why! you might ask...I want to learn everything about how a carb works and at the same time overhaul it. The one I bought is exactly the same make as my current one. I gave it a clean and its come up lovely. What I didn't do was open it up and mess around. I plan to use as is and work on the other in my spare time.

The header tank from a mrk4 golf is also shown. I have yet to buy the coolant pipes and associated parts.

Here are a few photos

The front seals before and after

The back end..before, showing a new spigot bearing

Finished look with new seal & sealing flange...Thanks Neil for the part numbers for the gasket and seal.

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

I then got to work on the Cam cover...changed the gasket and top up cap seal. Cleaned the cover, gave it a quick blow over with spray paint. Another job off the list.

I removed the fuel pump. I am replacing with new

The new fuel pump

I took time out from the engine and concentrated on associated bits that needed working on...painting time...

The new fuel tank got a coat

Followed by the the tank straps and engine bar. before..

After

I removed the fuel pump. I am replacing with new

The new fuel pump

I took time out from the engine and concentrated on associated bits that needed working on...painting time...

The new fuel tank got a coat

Followed by the the tank straps and engine bar. before..

After

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

I moved onto the front gearbox mount and quickly made the decision I was replacing for new..the rubber mount itself is quite perished. Vw heritage and justcampers sell them for around £120-130. I will need a new selector lever...the metal munchers have taken a what appears to be a bite sized chunk out of the top end. A rubber ring/sleeve was used to cover the offending article. I had fun and games trying to free it from the shift rod. I clamped the rod down and knocked the pin out. I heated up the shifter and off it came. Now I was able to inspect the shift rod bushing, support plates and bellows..

The knackered mount..

Work mate and G clamps came in really handy..

Metal muncher was ere!!

Ready for investigation

I need two bellows both have rips in them and the support plates need a once over, quite a collection of rust in and around the collars/openings. I will be looking at protecting them areas before I re install. The rear bush needs a clean..no evidence of cracks, I will probably use again..offer up a little grease before I refit it. I am not planning on overhauling the other end of the shift rod.

Over the last few days I have been thinking about the ignition system. I need to establish whether I have a distributor with contact breaker or a breakerless electronic ignition. I read the manuals and I believe I have a TZ-28H Distributer. It is very similar to the TSZ-2 Distributor. Now I know this I I can find out if the blue ignition coil I bought I am not clear on this..Do coils come with "inbuilt ballast resistors". I have read that all A engines from 79 on have a ballast resistor which is wired in series with the ignition coil. I need to find out if my coil will work for me. What I have learned is I need a control unit. I have got one..I need to ask the chap I got it from if it will suit the distributor I have.

A pick of my distributor. I need to clean the inside out. my next job...

Back soon...Thanks for looking ..

Tom

The knackered mount..

Work mate and G clamps came in really handy..

Metal muncher was ere!!

Ready for investigation

I need two bellows both have rips in them and the support plates need a once over, quite a collection of rust in and around the collars/openings. I will be looking at protecting them areas before I re install. The rear bush needs a clean..no evidence of cracks, I will probably use again..offer up a little grease before I refit it. I am not planning on overhauling the other end of the shift rod.

Over the last few days I have been thinking about the ignition system. I need to establish whether I have a distributor with contact breaker or a breakerless electronic ignition. I read the manuals and I believe I have a TZ-28H Distributer. It is very similar to the TSZ-2 Distributor. Now I know this I I can find out if the blue ignition coil I bought I am not clear on this..Do coils come with "inbuilt ballast resistors". I have read that all A engines from 79 on have a ballast resistor which is wired in series with the ignition coil. I need to find out if my coil will work for me. What I have learned is I need a control unit. I have got one..I need to ask the chap I got it from if it will suit the distributor I have.

A pick of my distributor. I need to clean the inside out. my next job...

Back soon...Thanks for looking ..

Tom

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

Hello...

Another busy day pottering around..

I refurbed all the bits I showed earlier, cleaned off the fuel expansion tanks and gave the fuel tank an extra coat of paint..just waxoil treatment left to do..especially on the top of the tank (ridged part). I have to repair (temp fix) an expansion valve. I cannot get one in the uk at the mo..There is a source in Germany just got to find the link..always the same when researching for stuff....sooo much info..here is a few more flicks...

A flick of all the bits I needed to sort out prior to sticking on the engine..

Fuel tank bits including the expansion tanks. I have some new low pressure braided fuel line and will be changing old for new..

A quick look at the valve that snapped when ripping out the old fuel tank...I plan to use an adhesive to mate the snapped pieces..a piece of tubing fed through to give a little support.

I received the new front gearbox mount and mounted it on the freshly painted back plate...looks lush compared to the old one..I also invested in an clutch alignment tool..thanks Aidan

I then got to work on cutting a piece of tinware to block of the half moon shape on the engine..this is to protect the fly wheel..nothing special..but a very important addition.

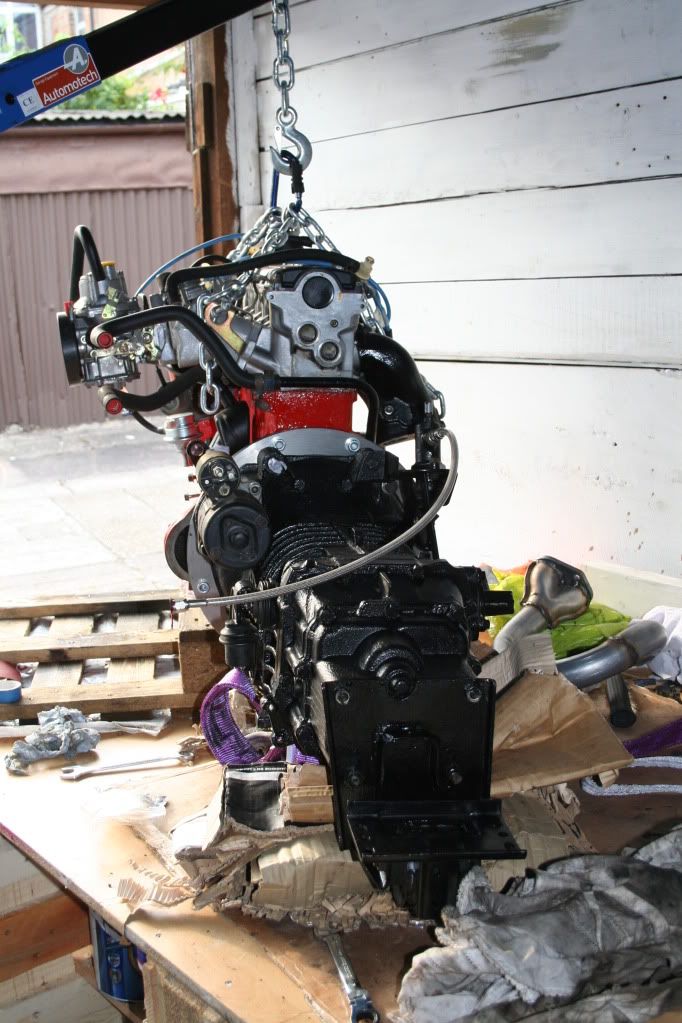

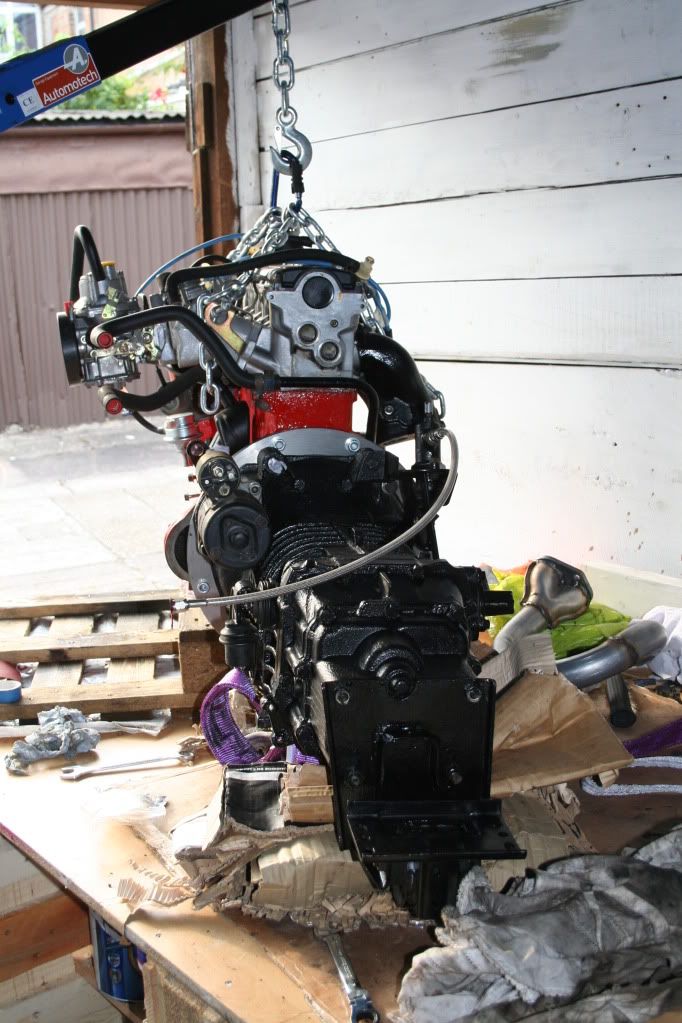

Then moved onto the flywheel, clutch and mating of the gearbox...

First the flywheel

A quick look at the clutch coming together..

Clutch disc..nicely lined up with the help of the tool..

Cover assembly

A tricky job lining the gearbox up..looking around for something that would help me bring it upto the level I needed...bricks wood and plenty of cardboard did the job..

Another view

Fitted the starter, clutch slave, bracket..here are a couple of flicks

Done for the day...just a couple of bits to get and I will be ready to start sticking it in the van...

Thanks for looking..

Tom...

Another busy day pottering around..

I refurbed all the bits I showed earlier, cleaned off the fuel expansion tanks and gave the fuel tank an extra coat of paint..just waxoil treatment left to do..especially on the top of the tank (ridged part). I have to repair (temp fix) an expansion valve. I cannot get one in the uk at the mo..There is a source in Germany just got to find the link..always the same when researching for stuff....sooo much info..here is a few more flicks...

A flick of all the bits I needed to sort out prior to sticking on the engine..

Fuel tank bits including the expansion tanks. I have some new low pressure braided fuel line and will be changing old for new..

A quick look at the valve that snapped when ripping out the old fuel tank...I plan to use an adhesive to mate the snapped pieces..a piece of tubing fed through to give a little support.

I received the new front gearbox mount and mounted it on the freshly painted back plate...looks lush compared to the old one..I also invested in an clutch alignment tool..thanks Aidan

I then got to work on cutting a piece of tinware to block of the half moon shape on the engine..this is to protect the fly wheel..nothing special..but a very important addition.

Then moved onto the flywheel, clutch and mating of the gearbox...

First the flywheel

A quick look at the clutch coming together..

Clutch disc..nicely lined up with the help of the tool..

Cover assembly

A tricky job lining the gearbox up..looking around for something that would help me bring it upto the level I needed...bricks wood and plenty of cardboard did the job..

Another view

Fitted the starter, clutch slave, bracket..here are a couple of flicks

Done for the day...just a couple of bits to get and I will be ready to start sticking it in the van...

Thanks for looking..

Tom...

- axeman

- Registered user

- Posts: 1256

- Joined: 07 Feb 2009, 19:50

- 80-90 Mem No: 6410

- Location: Smeeth kent country side

Re: 1.6td to Volvo b230a...

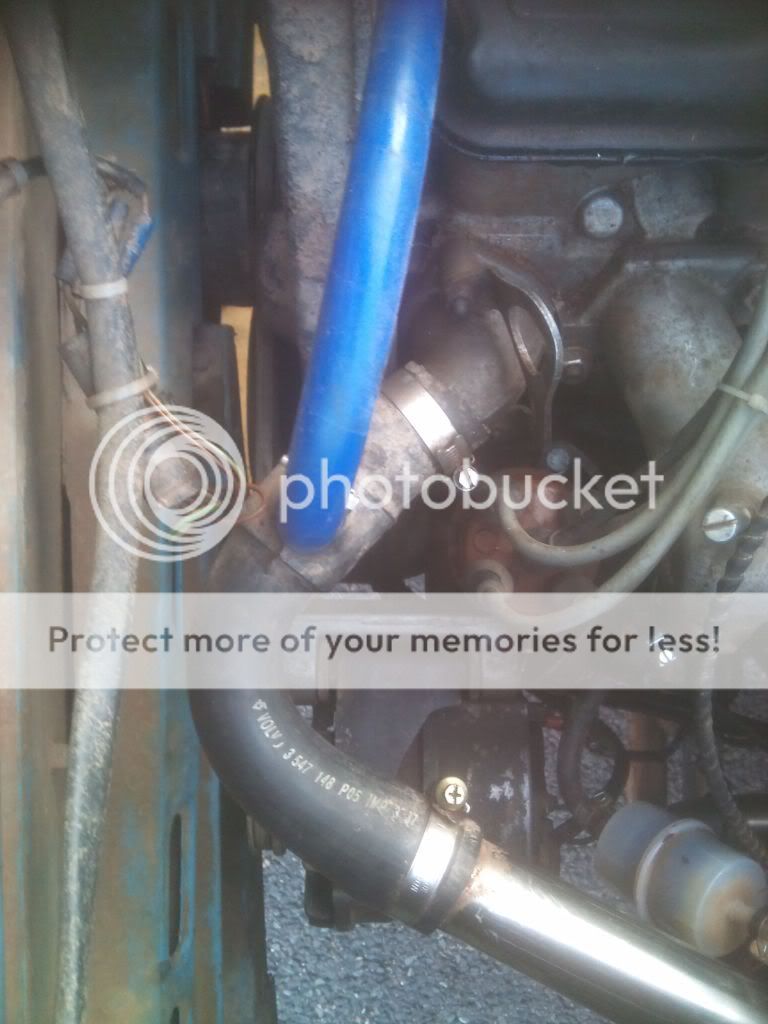

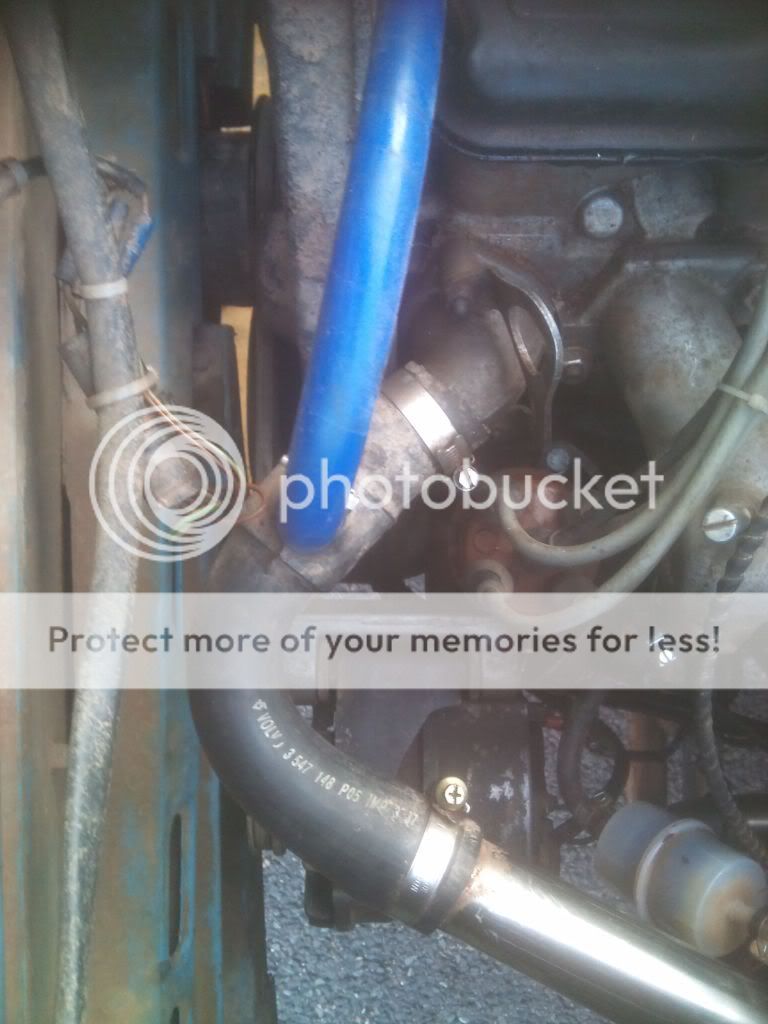

here you go tom

header tank filling the cooling system with a 16mm hose

expansion hose from the top of the tank to the hose which is past (in front) of the stat, from memory it is a 6mm hose. simple as that.

the hose from the turbo volvo i was talking about with the reducing T for the expansion hose

neil

header tank filling the cooling system with a 16mm hose

expansion hose from the top of the tank to the hose which is past (in front) of the stat, from memory it is a 6mm hose. simple as that.

the hose from the turbo volvo i was talking about with the reducing T for the expansion hose

neil

Back in the game with an uncut 2wd panel van

-

carpmaster

- Registered user

- Posts: 149

- Joined: 06 Sep 2010, 18:35

- 80-90 Mem No: 7658

- Location: Taunton Somerset

Re: 1.6td to Volvo b230a...

Thanks Neil

I am not in work until tomoz night..going to contact my Volvo friendly dealer and ask about the t piece..handy that you have shown the part number.

I have got my eye on a silencer for sale on ebay and I have been looking for a filter setup..no luck as of yet.

Going to order my rubber mounts tomoz from dye (wales) and ask about ignition amplifyer..Check with GSF about the coil I bought make sure it is one I need.

Hopfully hear from Ian soon about the engine supports..

I will keep you posted...

thanks again Neil

Tom

I am not in work until tomoz night..going to contact my Volvo friendly dealer and ask about the t piece..handy that you have shown the part number.

I have got my eye on a silencer for sale on ebay and I have been looking for a filter setup..no luck as of yet.

Going to order my rubber mounts tomoz from dye (wales) and ask about ignition amplifyer..Check with GSF about the coil I bought make sure it is one I need.

Hopfully hear from Ian soon about the engine supports..

I will keep you posted...

thanks again Neil

Tom

-

silverbullet

- Trader

- Posts: 17294

- Joined: 08 Jun 2009, 09:51

- 80-90 Mem No: 6908

- Location: Surrey Syncronaut #156

- Contact:

Re: 1.6td to Volvo b230a...

I suppose you'll be needing these then:

Whoops! I do of course mean these:

Whoops! I do of course mean these:

1985 Oettinger 3.2 Caravelle RHD syncro twin slider. SA Microbus bumpers, duplex winch system, ARC 7X15 period alloys