Its been a while since there was any movement on this project, partly because of work, partly because of using the syncro for what it was meant for and partly because it was Ali's 50th last weekend!

Anyway I've been getting a bit fed up with what feels like like a lack of progress so thought that I would try and get on with something I know a bit about and build up the heads...

First grind in the valves. I still use the old fashioned way with a valve grinding tool and paste

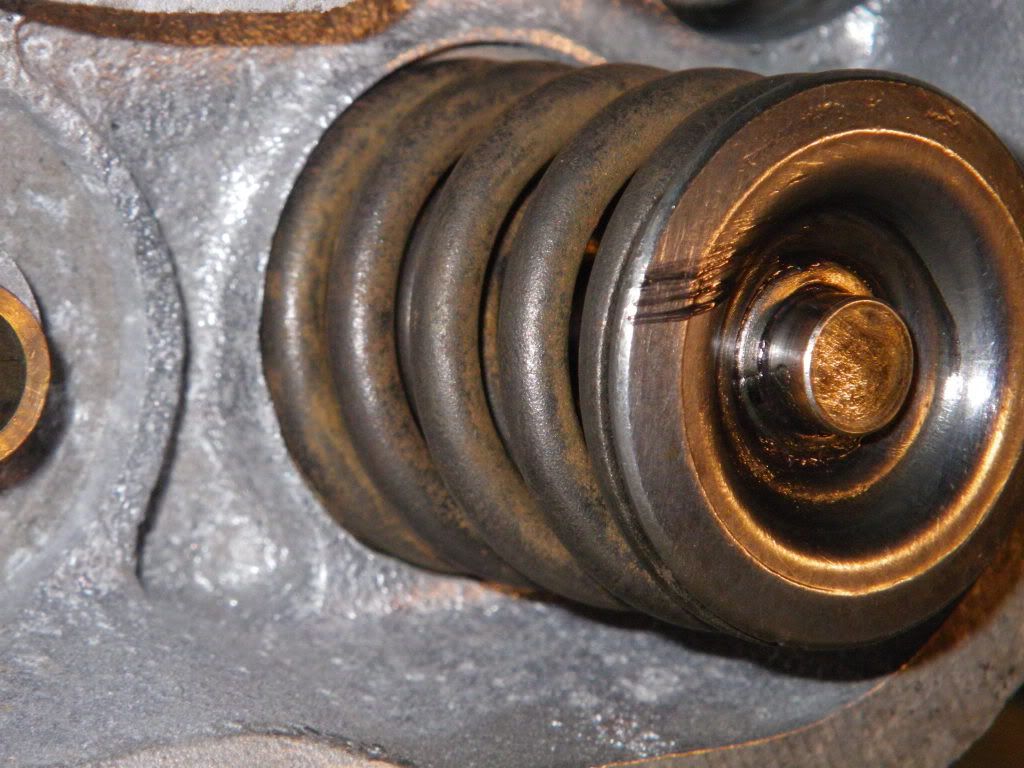

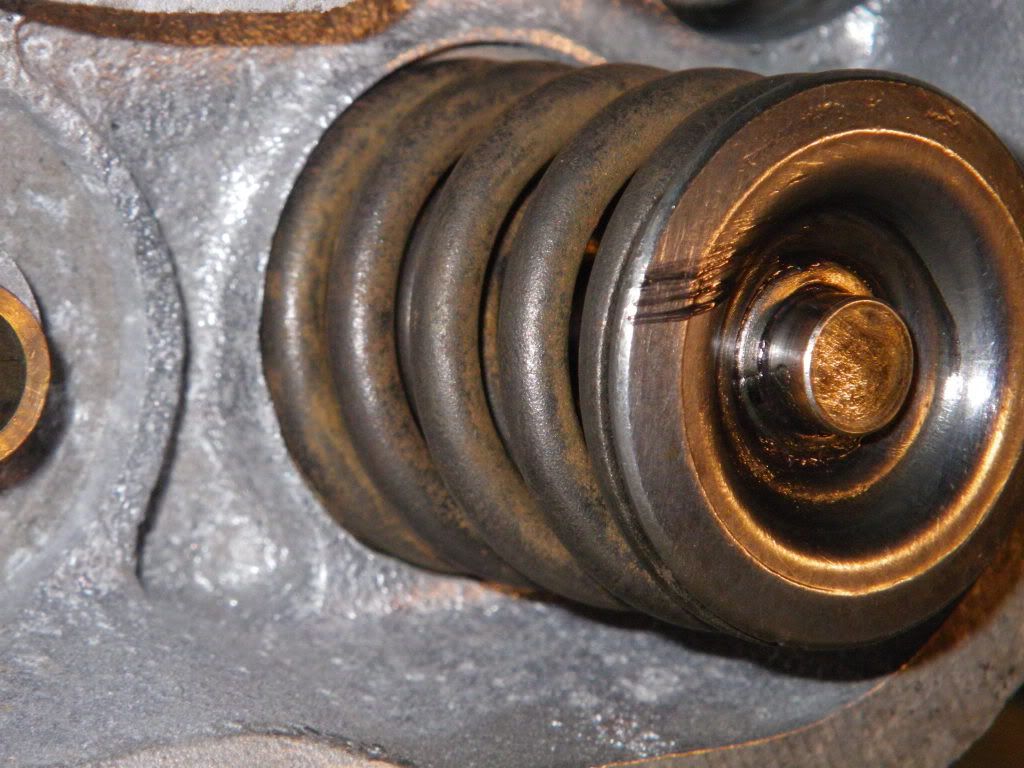

A bit of elbow grease leaves a nice even dull grey sealing surface around each valve and seat

I put a smear of oil on the valve stem so it doesn't wear

Then everything gets washed in Jizer or similar, rinsed off, blown dry with compressed air and then repeated until you could eat your lunch off it.

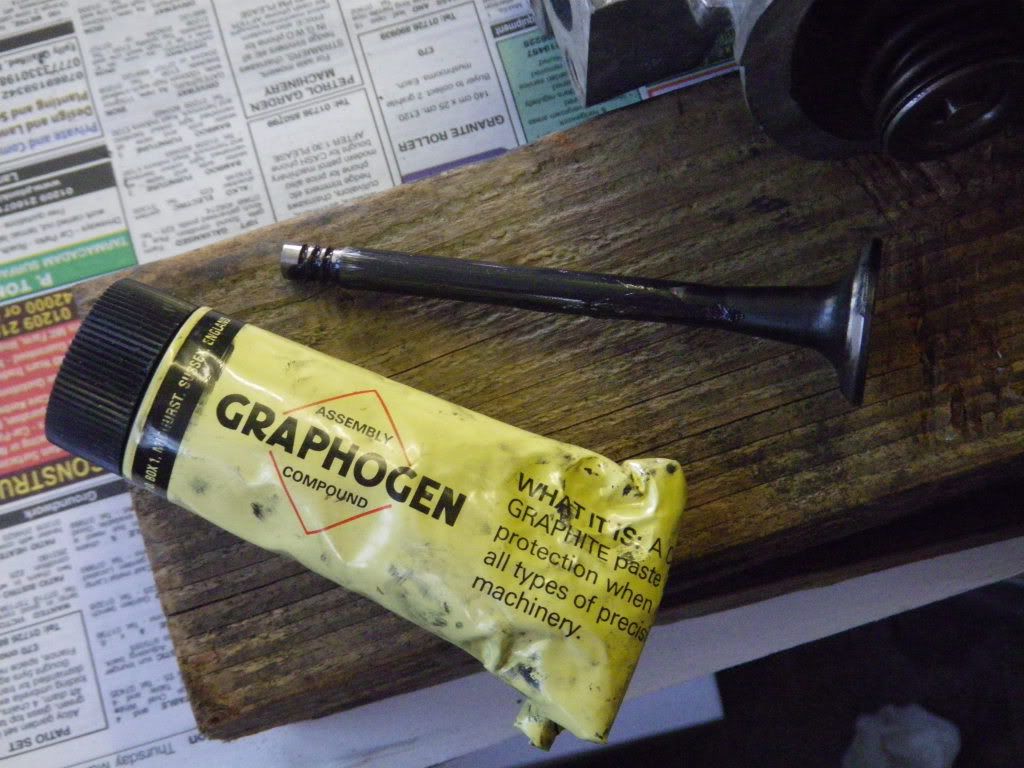

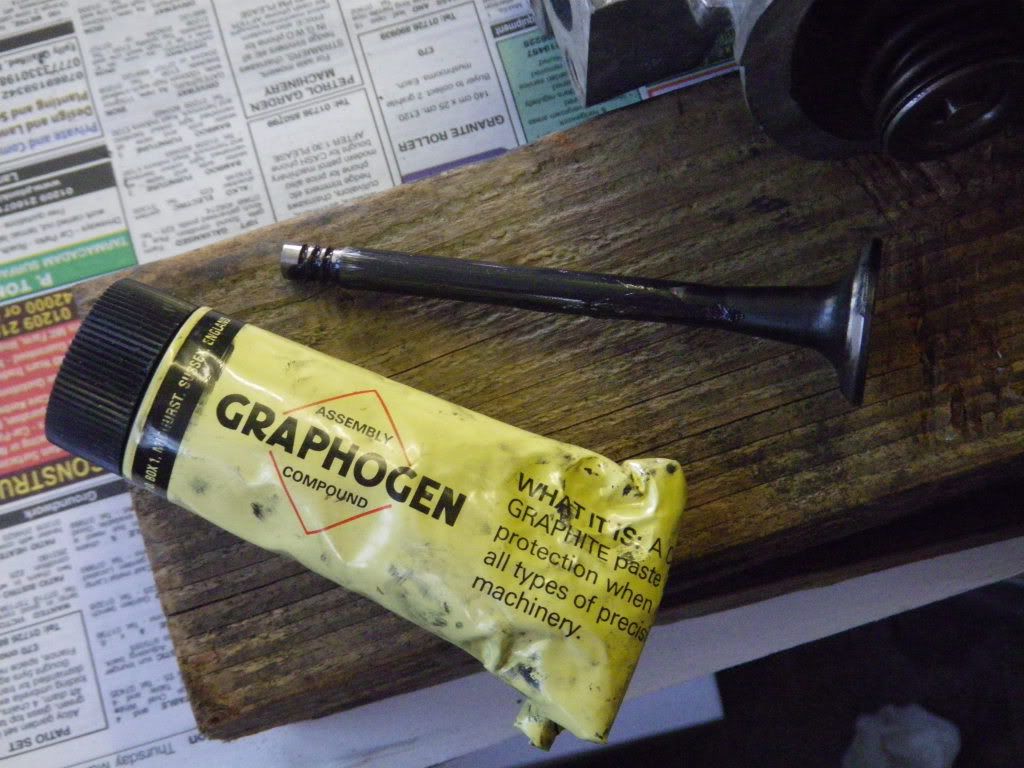

Springs, collets and spring caps all set out and then a smear of Graphogen on the valve stem:

Valve in place

Inner and outer springs on and spring cap:

Then compress the springs:

And the fiddly bit -getting the collets into place. I use a dab of grease and various fine instruments

And eventually get them into place:

Release the spring compressor, clean up and only seven more to go:

And the finished article:

Now seal them up in plastic bags so that no gritty bits can get into them and back to sorting out pistons and liners etc.