I was going to O ring it but I just have not got around to it so I took the plunge and fitted it as is.

1st job was to weld up my pump puller that I broke

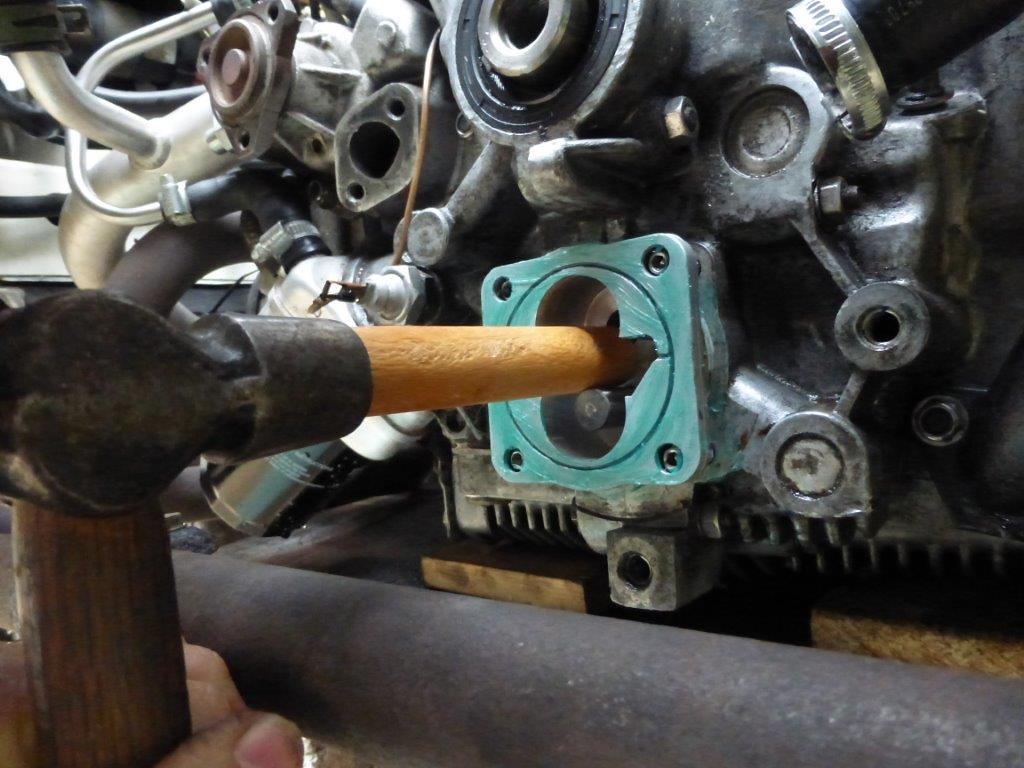

P1100138 by Paul_Barr, on Flickr

P1100138 by Paul_Barr, on Flickrsilencer off, tin shroud off, support engine, engine bar off, engine cradel off, crank pulley off, water pipes off....

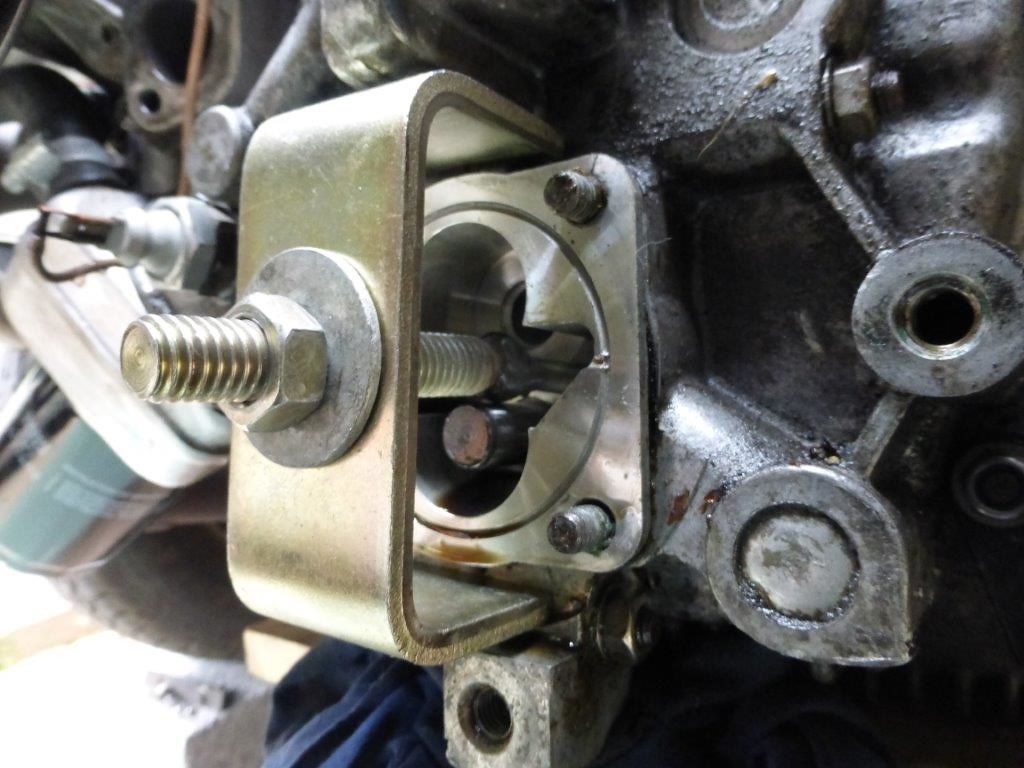

P1100139 by Paul_Barr, on Flickr

P1100139 by Paul_Barr, on Flickrnew pump is deeper so need to grind the cover plate down to about 8mm on the vertical sides, then check it fits on a spare case

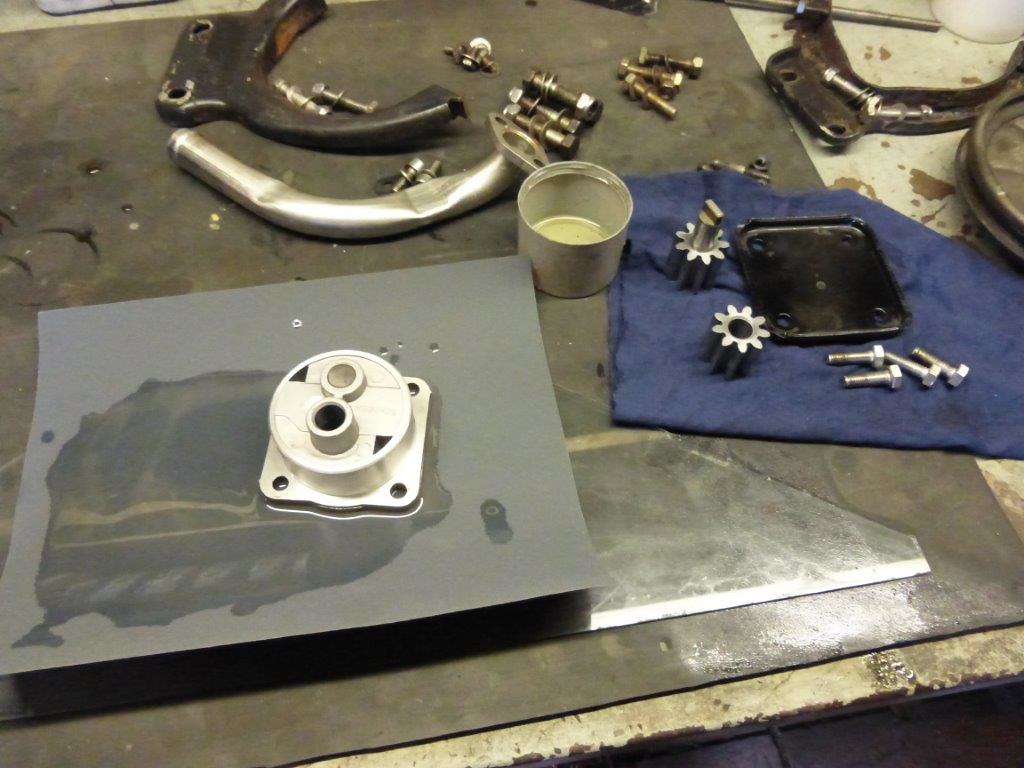

P1100141 by Paul_Barr, on Flickr

P1100141 by Paul_Barr, on Flickrstuds are long enough to pull them out 5mm

P1100143 by Paul_Barr, on Flickr

P1100143 by Paul_Barr, on Flickra bit of fettling the pump to get almost zero end float

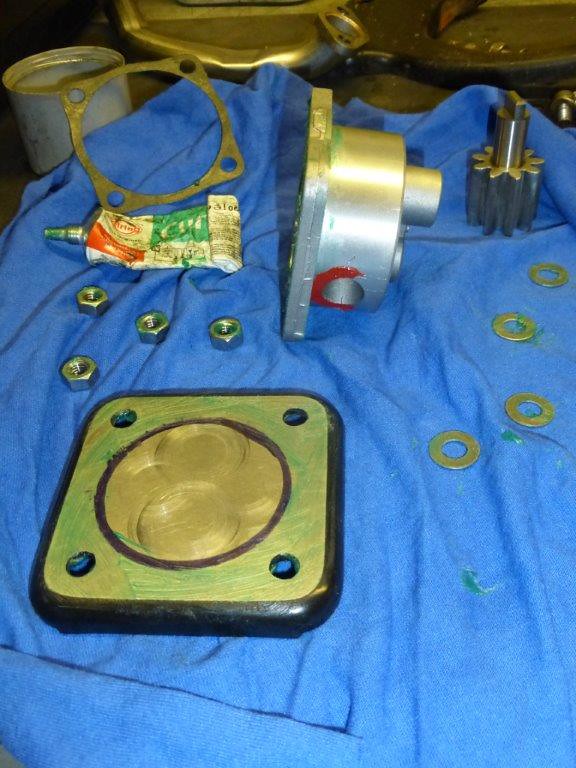

P1100144 by Paul_Barr, on Flickr

P1100144 by Paul_Barr, on FlickrCuril T in place of a gasket and some Dirko HT around the inlet and outlet in horseshoe shapes so the sealant does not end up in the oilway, the Dirko was done yesterday and left 24 hours to set.

P1100146 by Paul_Barr, on Flickr

P1100146 by Paul_Barr, on Flickr P1100147 by Paul_Barr, on Flickr

P1100147 by Paul_Barr, on Flickr P1100148 by Paul_Barr, on Flickr

P1100148 by Paul_Barr, on Flickr P1100151 by Paul_Barr, on Flickr

P1100151 by Paul_Barr, on Flickrwater pump has play so ideal time to swap it

P1100154 by Paul_Barr, on Flickr

P1100154 by Paul_Barr, on Flickrall back took longer than expected because I just had to paint stuff

P1100160 by Paul_Barr, on Flickr

P1100160 by Paul_Barr, on Flickrplease with the results. this was 2.5bar

P1100162 30mm pump by Paul_Barr, on Flickr

P1100162 30mm pump by Paul_Barr, on Flickrthis was 1.5 bar

P1100168 30mm pump by Paul_Barr, on Flickr

P1100168 30mm pump by Paul_Barr, on Flickr