Page 1 of 3

Bessie getting done up for next year and getting worse

Posted: 16 Oct 2011, 06:59

by Bessie the camper

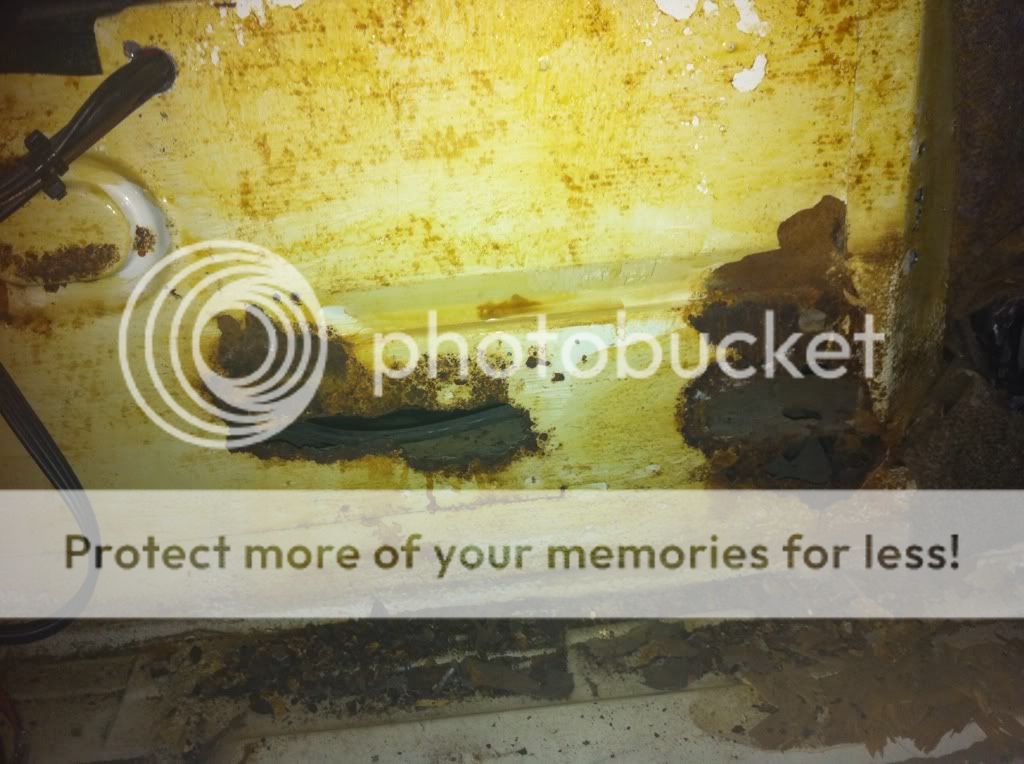

Has decide to do Bessie up fed up of seeing seam rust so here some photos so far

So far so good

Then

Gets worse

I best see if I can remember how to weld been a few years

More up dates as I go along

Re: Bessie get done up for next year

Posted: 16 Oct 2011, 08:12

by Mickyfin

I really need to address my seams too, but with winter on the doorstep, its going to have to be next year now.

Will follow your progress with interest

Re: Bessie getting done up for next year and it gets worse

Posted: 22 Oct 2011, 18:14

by Bessie the camper

Day two of doing van up

First make new garage

Then interior which wasnt that bad to do

All out

Who gues the floor down

Then this

And more

Final one I hope

Re: Bessie getting done up for next year and getting worse

Posted: 22 Oct 2011, 22:05

by Nij

This is why I dread tackling the bodywork on mine.

I used to be able to mig (about 10 years ago), I can arc but I dont think thats viable for bodywork lol but my main issue is having no where to do it.

Re: Bessie getting done up for next year and getting worse

Posted: 23 Oct 2011, 03:49

by Bessie the camper

I'm lucky I've got a big drive and a big gazebo

Re: Bessie getting done up for next year and getting worse

Posted: 23 Oct 2011, 18:24

by meggles

I use an arc for bodywork. Just use an extra rod as a filler rod and it cuts down the amount of holes you blast into the panels. Good luck, hope you get there in the end, autosleeper's are well worth the effort!?

Re: Bessie getting done up for next year and getting worse

Posted: 23 Oct 2011, 18:49

by Bessie the camper

Re: Bessie getting done up for next year and getting worse

Posted: 23 Oct 2011, 18:56

by Nij

meggles wrote:I use an arc for bodywork. Just use an extra rod as a filler rod and it cuts down the amount of holes you blast into the panels.

Sorry can you explain more mate?

Re: Bessie getting done up for next year and getting worse

Posted: 23 Oct 2011, 19:04

by jimpainter

I have seen things about using arc for bodywork. I havent actually seen it done though. But i would imagine it is quite difficult to control though.

Re: Bessie getting done up for next year and getting worse

Posted: 23 Oct 2011, 19:07

by Nij

jimpainter wrote:I have seen things about using arc for bodywork. I havent actually seen it done though. But i would imagine it is quite difficult to control though.

my thinking exactly buddy

Re: Bessie getting done up for next year and getting worse

Posted: 23 Oct 2011, 20:19

by jimpainter

Frost do something in there catalogue for arc welding bodywork and also spot welding with an arc welder. It just seems very industrial if you get my meaning. Arc welding has always seemed like a firce way of welding and suitable for welding thick plate.

Re: Bessie getting done up for next year and getting worse

Posted: 24 Oct 2011, 08:17

by meggles

Mig is better I'm sure but as I don't have a mig I don't have a choice.

Nij, when gas welding you use the flame to "melt" the welding rod into the join in the plates you're welding. I use an arc in the normal way whilst also holding another rod (with flux coating removed) into the "flame" that the rod in the holder makes. If you see what I mean. That way you get more metal into the joint. Just got to make sure you still get enough penetration though. With practice you can do a decent weld. A little more grinding may be required though. It won't work on very thin corroded metal though, but then you should be replacing that anyway in my opinion.

Hope this explains it.

Re: Bessie getting done up for next year and getting worse

Posted: 25 Oct 2011, 17:37

by Bessie the camper

Started the cutting

How do you weld the top section push the new section under old bit and spot weld so no water gets in then filler or do you cut to the top and welded all the way a cross ???

Had to buy new toy too

Re: Bessie getting done up for next year and getting worse

Posted: 26 Oct 2011, 12:34

by jimpainter

I usually take some time, measure,measure and measure again then butt weld. It does take time though. Or you could joggle the panel and then spotweld. The later is the easiest way.

Re: Bessie getting done up for next year and getting worse

Posted: 26 Oct 2011, 16:05

by boatbuilder

Bessie the camper wrote:Started the cutting

How do you weld the top section push the new section under old bit and spot weld so no water gets in then filler or do you cut to the top and welded all the way a cross ??

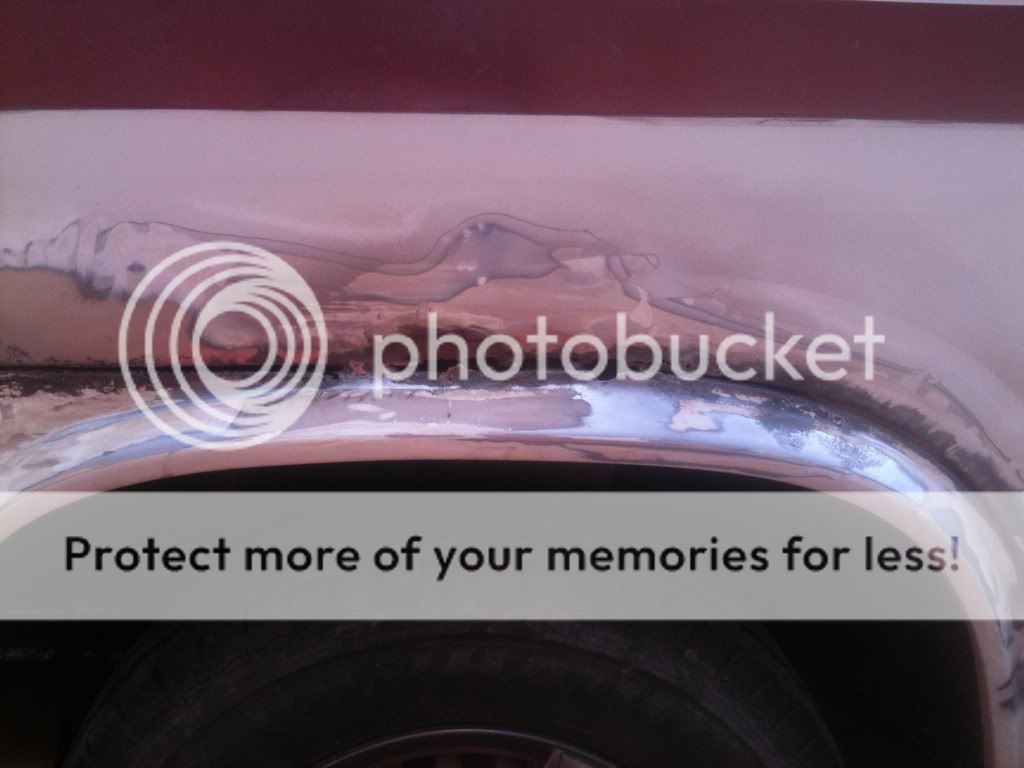

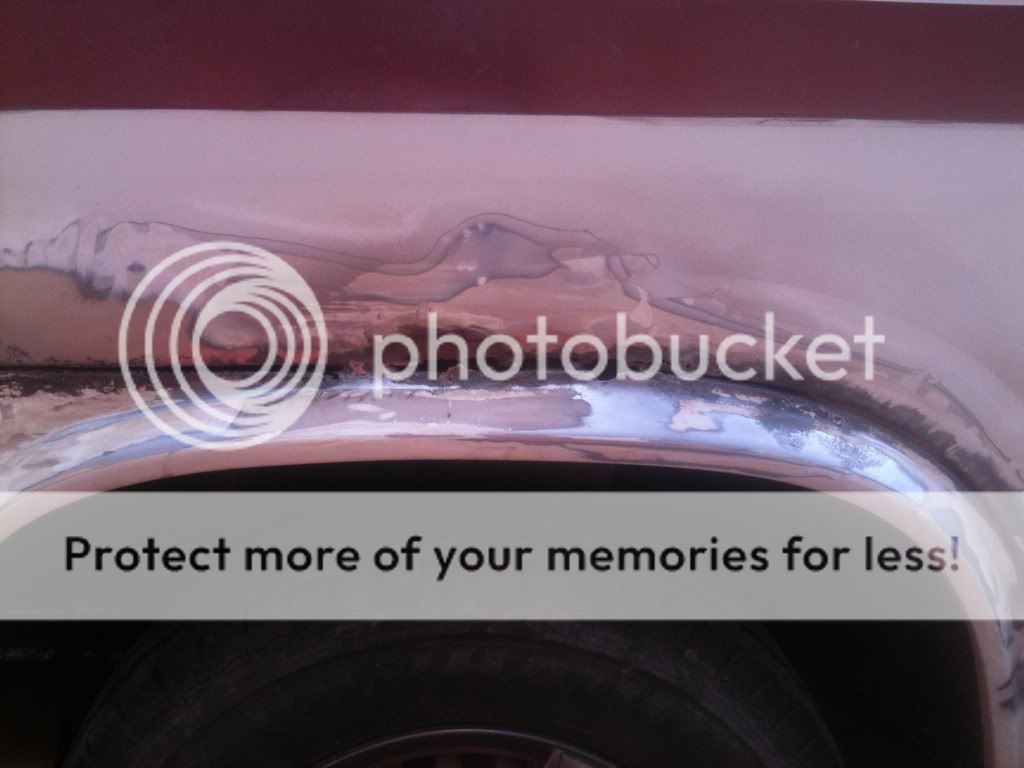

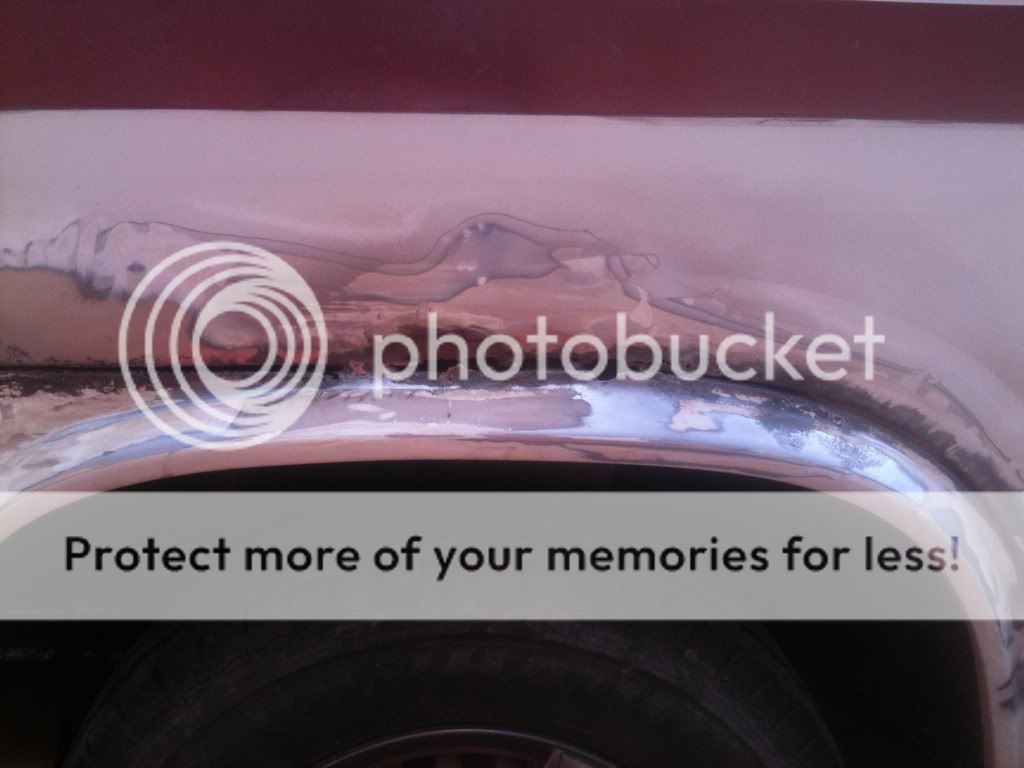

I overlapped mine a bit, with the new panel on top of the old...just overlapped by about 12mm or so, with plenty of weld-through primer in between. Then I puddle welded every couple of inches. Then I just seam sealed the join on the inside and fillered the join on the outside with a 50/50 mix of filler and chopped fibreglass. Then a skim of normal filler on top. Lead loading would be better, but I can't stretch that far at the moment!

s/ac327/bgb75/8c773e19.jpg[/IMG]

s/ac327/bgb75/8c773e19.jpg[/IMG]