Page 1 of 3

Low compression.

Posted: 16 Nov 2016, 19:53

by bigbadbob76

Ok, so i recently bought my '86 dg engined camper, I hadn't planned on another project as my garage is full but hey-ho, i did it, more fool me. haha.

She's smoking worse than I do, nice blue oil smoke and following drivers gag on the fumes so I did a compression test to see how bad it is.

results-

W.O.T, cold. (ok, I know it should be at working teperature as the choke is closed when cold etc but that's immaterial with these results).

cyl dry wet

1 118 125 psi

2 120 127 psi

3

75 125 psi

4 125 127 psi

Test repeated the following night with same results within a psi or two.

Looks like all are low but cyl 3 has major issues.

I checked my guage against a calibrated one at work and it's reading a couple of psi or so low but close enough.

Plugs are a nice tan colour after a decent run and a bit sooty after just idling.

No oil or bubbles in the coolant. no mayonaise in the oil, slight weep from both head rubber seals.

Oil leak from the crankshaft oil seal.

Looks like the lump will be coming out over the winter.

I've done engine rebuilds before, one on a flat twin 2cv6 and one on an inline four suzuki bike. so flat four will be my first water cooled but shouldn't be beyond me especially following some of the engine rebuilds on here. So thanks for the info guys, gives me confidence to get stuck in there.

If anyone has experiance of one cylinder being significantly lower than the rest and what the cause was I'd be glad to hear your experiances.

If i'm lucky it's a stuck ring, if I'm unlucky it's a broken ring that's scored the bore.

Fingers crossed I don't snap and head studs.

Re: Low compression.

Posted: 16 Nov 2016, 21:14

by itchyfeet

Because they are loose barrels it's not the end of the the world if the barrel is ruined.

Head studs should be treated with care when releasing, if they are corroded badly then nothing will help but if the nuts are just rusted on heat will free them up before releasing.

could be rings or valve guides or both, please let us know how you get on, rebuild threads are very welcome

Re: Low compression.

Posted: 16 Nov 2016, 21:55

by bigbadbob76

Thanks Itchyfeet.

Will post more once I drop the lump out, it'll probably be more of a refresh than a ground up re-build.

I'm following a few re-build threads on here so know what i'm letting myself in for. as you say, new barrells and pistons wouldn't be the end of the world.

And valve guides are replacable with care.

I've seen a few pics of studs corroded thin near the top, are these removable using a stud extractor near the bottom or is it a lost cause by that stage?

cheers.

BBB.

Re: Low compression.

Posted: 17 Nov 2016, 06:14

by itchyfeet

I'm sure studs are removable but it may take some considerable skill to do it.

What2do removed a stud from the engine currently in my van, it was snapped at the case by a previous owner.

He had to weld a nut onto remove it ( welded inside of nut) and by all accounts if took many hours of trying before it finally came out.

Re: Low compression.

Posted: 17 Nov 2016, 09:21

by what2do

A stud broken level with the surface poses no greater difficulty than a stud that breaks with threads exposed. Don't let a flush break deter you from getting it removed. They do come out, some a lot easier than others. Anyway, yours may not break. Are you feeling lucky?

Re: Low compression.

Posted: 17 Nov 2016, 09:23

by itchyfeet

I have two engine cases to practise on when you find me a suitable welder.

When you did mine I was reluctant to remove the crankcase nut that was so close, I think that would have made it easier.

Re: Low compression.

Posted: 17 Nov 2016, 11:58

by bigbadbob76

Cheers guys. That's reassuring.

I'll see what happens when I get the heads off, basically this engine needs to come out and be sorted anyway so there's no harm in trying. nice to know there's ways and means to get a stud out if it does snap flush, I like the idea of welding down through the nut as long as I can get enough weld penetration into the stud without damaging the block.

Assuming they don't snap and are not corroded too much is it best practice to replace them or leave them alone?

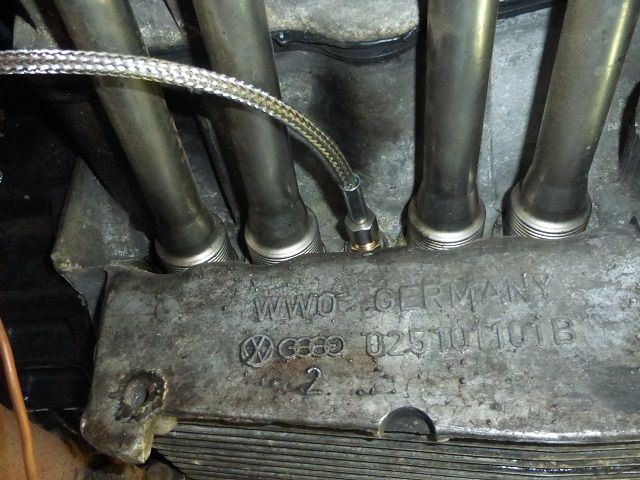

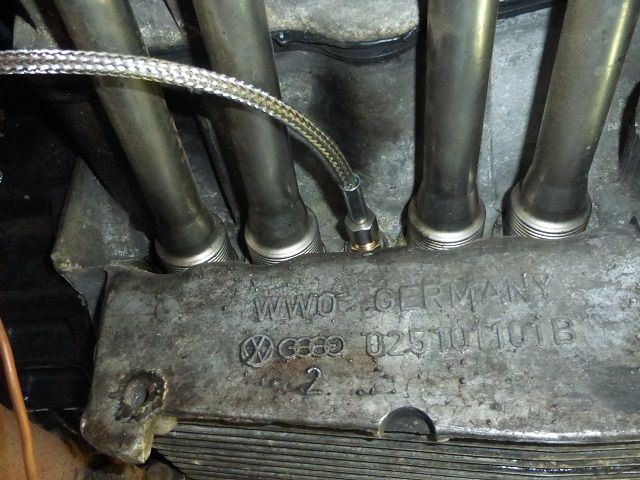

I've read on here that "studs are less likely to break on later engines" what counts as a later engine? is this just an age or mileage thing or were the studs different on "later engines"?

Re: Low compression.

Posted: 17 Nov 2016, 12:41

by itchyfeet

late engine has B suffix on case, extra oil pressure switch, bigger M10 bolt by flywheel and differences inside that you can't see from outside.

Yes studs are less likely to corrode on late, different steel formula I'm told, no don't change unless they are bad, I have left small pitting before.

seen this have you?

https://club8090.co.uk/forum/viewtopic.php?f=37&t=156223" onclick="window.open(this.href);return false;

This is the stud What2do removed the broken bit, there was no major corrosion, what had happened I think is the nut had rusted to the stud and was not heated before removal 50Nm is not huge for an M10 so broken studs are IMO largely because of rusted on nuts.

Re: Low compression.

Posted: 17 Nov 2016, 14:09

by bigbadbob76

Thanks for the "heads up" Paul, and for the link and pics.

I'll check for the B suffix and heat the nuts to be sure before trying to remove them and also feel for "spingyness".

I'll post pics of the offending studs once I get in there and get advise whether they're ok.

Glad I found this forum, good to know the risks or not before I start.

Good job by What2do to get that stud out. What kind of welder was used? I have a choice of 100A mig or a dodgy old stick.

As I say, fingers crossed mine are fine but best to know worst case.

Re: Low compression.

Posted: 17 Nov 2016, 14:31

by kevtherev

I've never had a snapped stud.

I have always heated the nuts up to cherry red and undone them easily.

Re: Low compression.

Posted: 17 Nov 2016, 15:00

by bigbadbob76

Sounds good Kev.

not sure if I can get to cherry red with a disposable can torch, could weld a blob on top I guess.

Re: Low compression.

Posted: 17 Nov 2016, 20:06

by kevtherev

bigbadbob76 wrote:Sounds good Kev.

not sure if I can get to cherry red with a disposable can torch,

No you need an oxy acetylene setup.

I have used one at a local garage, once the engines out, and everything's off, it's more transportable.

Re: Low compression.

Posted: 17 Nov 2016, 20:13

by itchyfeet

kevtherev wrote:

once the engines out, and everything's off, it's more transportable.

yep, if it fits in a VW polo with the rear seats up it fits in almost any car.

2 man lift in , slide it down a plank to remove

Re: Low compression.

Posted: 17 Nov 2016, 21:20

by bigbadbob76

I'm sure I can find someone with oxy-propane to get em good and hot.

If it goes in a polo it'll be fine in the ranger.

Got plenty of planks to slide it on.

Re: Low compression.

Posted: 26 Nov 2016, 16:16

by bigbadbob76

Having replaced my starter bush, I did another compression test as my starter was labouring before.

Also did it hot this time.

Compression on the cylinder that was seriously low last time has come up to meet the others.

All are still low at 115-125psi.

Can I read anything from this?

Engine is coming out anyway as it smokes and leaks oil and water from both ends but I was just curious about the bad cylinder being better when hot and/or cranking faster, but the others being the same.

When I did a wet check last time it made a big differance so maybe a recently run worn cylinder has oil in the bores?

Comments welcome.