Flywheel timing mark confusion

Posted: 20 Aug 2016, 11:49

1.9 diesel normally aspirated engine using the original flywheel and clutch from the 1.6D cs that I took out.

I can't see any marks on the actual flywheel but it does have a raised metal edge bolted on? Not sure if that's part of the clutch housing or not.

Anyway, this does have timing marks on, but I have no idea which is meant to be what. Need to find TDC as I don't think it is lined up properly with the cam shaft.

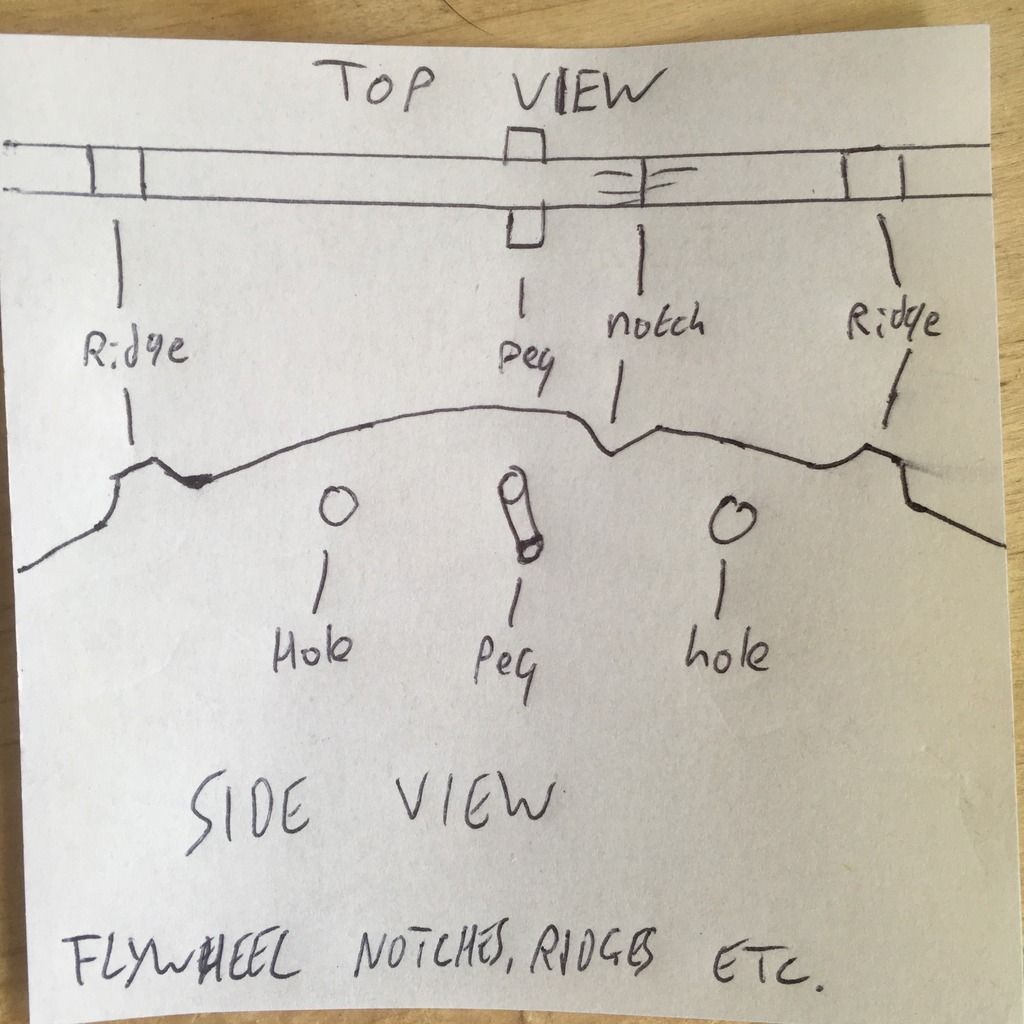

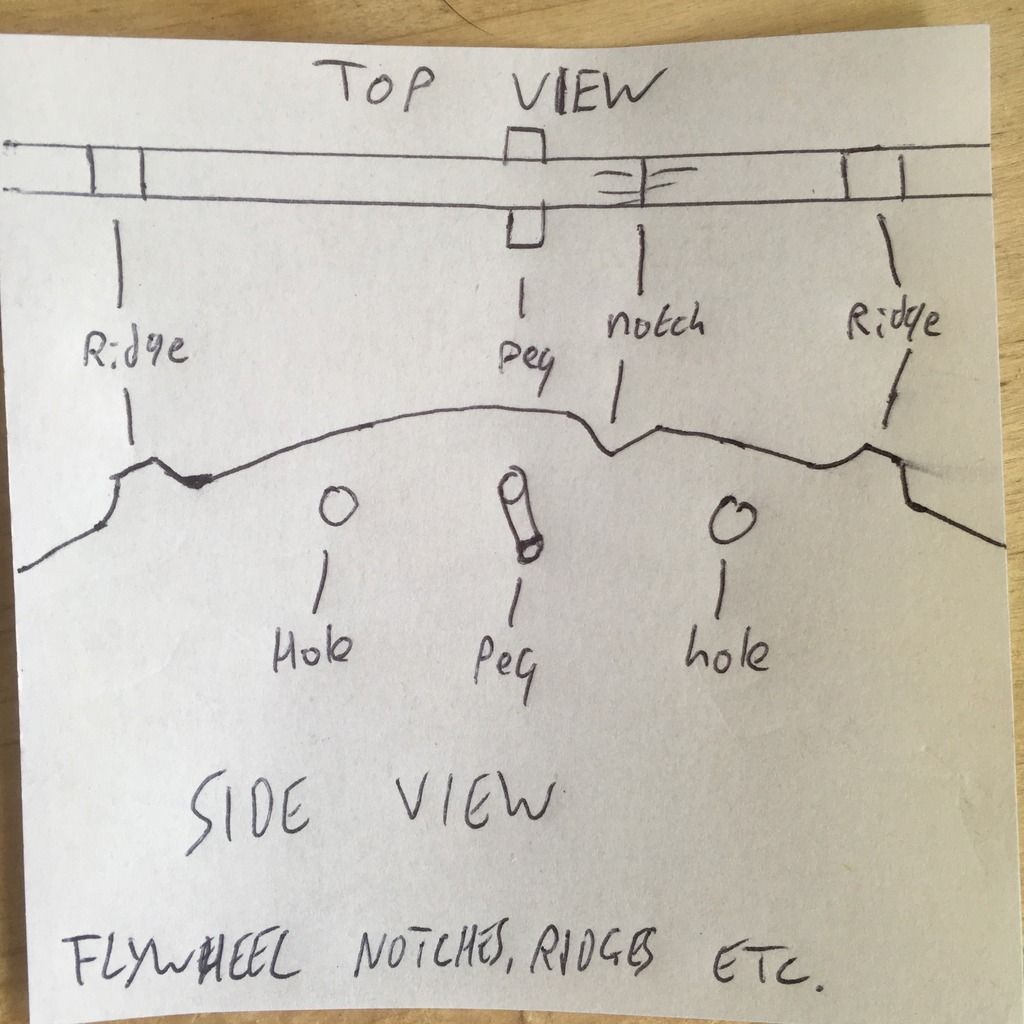

The picture shows a diagram of the rim viewable through the bellhousing inspection hole. I've done a top view and side view.

There are raised lips (for timing tool?), holes, a peg and a notch. I don't know which is meant to be which.

Any help interpreting would be greatly appreciated. Van is currently off the road until this is sorted.

I can't see any marks on the actual flywheel but it does have a raised metal edge bolted on? Not sure if that's part of the clutch housing or not.

Anyway, this does have timing marks on, but I have no idea which is meant to be what. Need to find TDC as I don't think it is lined up properly with the cam shaft.

The picture shows a diagram of the rim viewable through the bellhousing inspection hole. I've done a top view and side view.

There are raised lips (for timing tool?), holes, a peg and a notch. I don't know which is meant to be which.

Any help interpreting would be greatly appreciated. Van is currently off the road until this is sorted.