What goes wrong inside a T3 gearbox / transmission

Posted: 13 Feb 2015, 18:54

I saw this on Facebook, it's taken from the Samba forum written by Michael Ghia

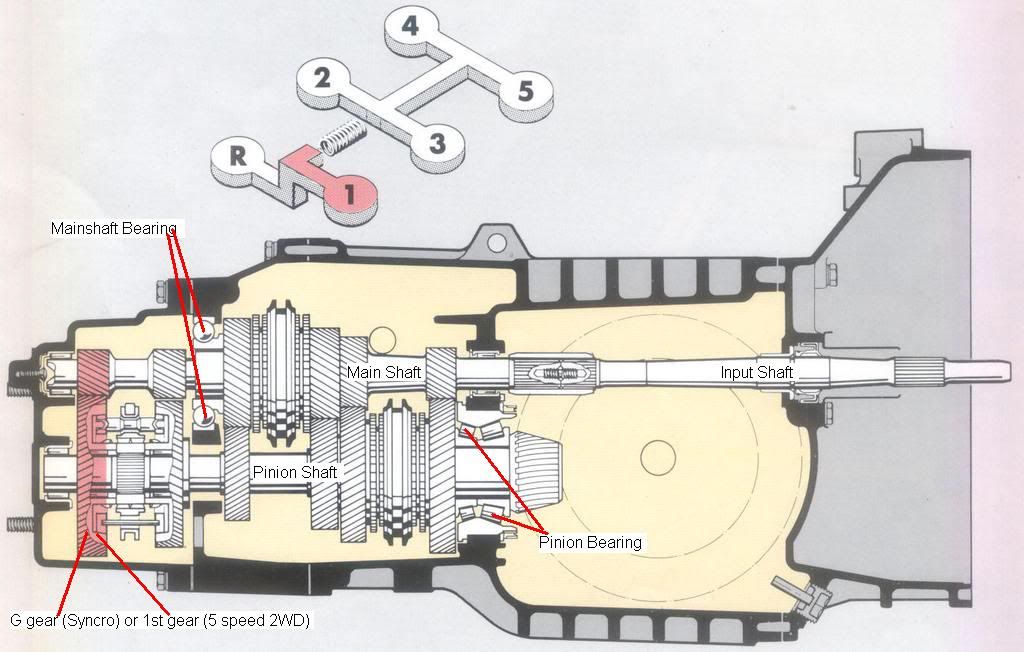

SyncroGhia wrote:A good illustration of what goes wrong inside a Syncro or 2WD gearbox.

This is an illustration of a 5 speed 2WD gearbox but as the Syncro gearbox is basically the same (for the purposes of this post), we can use this to illustrate what happens when pinion or mainshaft bearings wear or move.

When you hear someone saying that "the pinion bearing has failed", it means that it's worn enough for the pinion shaft to be able to move forwards and backwards in the case.

This does a number of things. Firstly, it moves the pinion head away from the crown wheel/ring gear so that the mesh pattern is no longer correct and the load is no longer spread evenly across the majority of the teeth of both the crown/pinion. There is an audible change when the shaft moves from it's furthest point in one direction to it's furthest point in the other direction. Obviously this will be when you are on and off throttle as the load changes respectively. This wears the crown/pinion very quickly through the hardened surface and causes the pitting on the teeth closest to the smallest end of the pinion and then starts taking chunks out of the crown wheel/ring gear!

The second thing is that with the pinion shaft moving forwards in the casing, G gear (in a Syncro) or 1st gear (in a 5 speed 2WD) gets squashed between the Synchro hub (which is fixed to the pinion shaft) and the support bearing in the end casing. The more the pinion shaft moves, the more load goes through to this set of components until the needle roller bearings (which are supporting G or 1st gear) get squashed, the bearing surface on the pinion shaft gets knarled up, G/1st gear gets knarled up and the small bearing in the end of the casing dies. Very messy. Believe it or not, this in itself doesn't create a whole lot of noise so the only way you know something is wrong is from the noise from the crown/pinion being in the wrong position in relation to each other.

In extreme cases (no pun intended), 2nd gear (in a Syncro or 3rd in a 5 speed 2WD) get's squished as well and it becomes impossible to select it without a huge crunch!

If your gearbox is noisy... there's a reason!!

Ok onto the mainshaft.

I've just put the spare gearbox into Limey because it started jumping out of 4th gear (5th gear in a 5 speed 2WD). The reason for this was that the mainshaft bearing was moving in it's casing. This was allowing the whole mainshaft to move forwards in the case.

If you look at the mainshaft bearing, to the right you'll see a gear. Right again from that are 2 sets of smaller teeth and then the selector ring. When you select 4th gear, you pull the selector ring over both of the smaller sets of teeth between the selector ring and 4 gear. If you imagine the mainshaft moving forwards (or to the left for this illustration), the selector ring would stay in it's normal position and effectively move to the right... heading back towards neutral. This puts your selection of the gear only half in/out. If you've ever missed a shift, you'll have 'half' selected the gear and the gearbox throws it back out of gear. This is what my gearbox was doing in Limey.

The cut of the gears cause a load pulling the mainshaft forwards in the case.

The mainshaft bearing is held in place by the next housing and by the bearing being a very snug fit into it's casing. However, if the bearing can move just a little... it slowly hammers a bearing shaped imprint into the next casing. If you have lots more torque than standard (like Limey) then this problem is made worse. If you're towing over 3 tons at 60 mph up a hill flat out with lots more torque... this is made much much worse

You can see the 'hammered' imprint in the R+G housing here.

I hope this helps anyone wondering what goes wrong inside a T3 gearbox.

MG