Page 1 of 11

Oops!!

Posted: 22 May 2013, 19:46

by sarran1955

Re: Oops!!

Posted: 22 May 2013, 19:57

by horizontal kipper

Oh dear not another one

jinx over on vzi has lots of type 4 motor spares he may have a good CU case if your stuck.

Re: Oops!!

Posted: 25 May 2013, 18:03

by sarran1955

Hello,

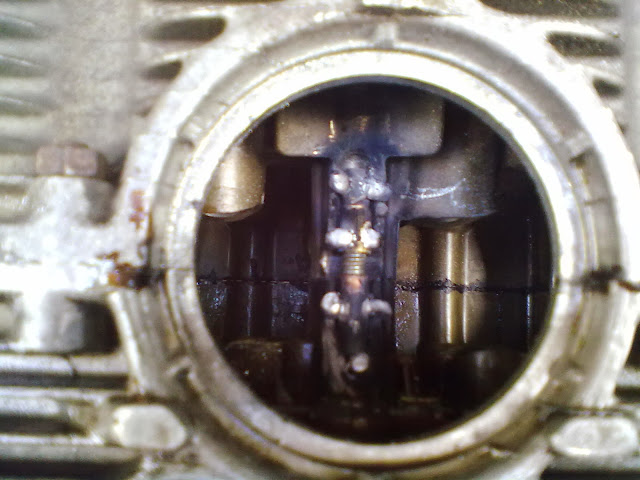

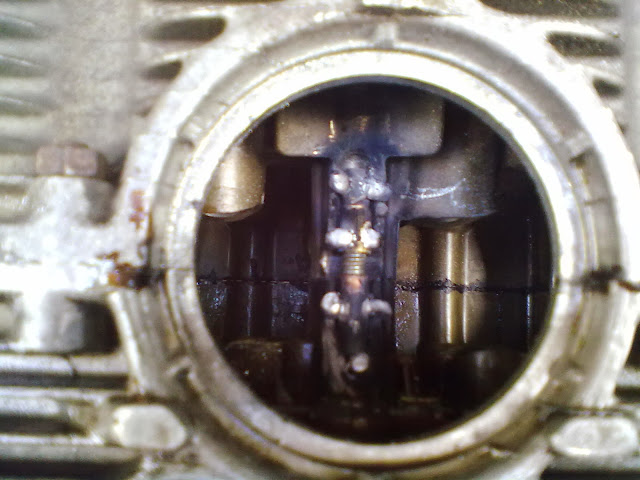

Well, I split the case today, and as you can see there is serious damage to both sides:

The sump plate bolt had been progressively over tightened, presumably to stop oil leaking around the sump plate..

Eventually the cross bolt gives way....

and there is oil all over the place

This is the RHS, with the bolt hole all the way through, .... peeled like a banana...

This is the 'blind' side.....

So much force was used on the case that the cross bolt ended up like this:

However, all, IMHO, is not yet lost....

If I get made a heat sink copper bar to sit in the cam bearing housings, and a sleeve for the bolt housing..

then I reckon welding surgery is on.....

Hopefully the patient will survive!!

Cordialement...

Re: Oops!!

Posted: 25 May 2013, 18:29

by 300CE

Keep us informed on how you get on Sarran! Always good to see how these kind of problems are resolved

Re: Oops!!

Posted: 25 May 2013, 19:17

by smnbyt

As it happens I'm sure I have a CU case in my loft I shall look tomorrow if you wish??

Simon

Re: Oops!!

Posted: 25 May 2013, 20:10

by sarran1955

Hello,

Please do.....

We will do photos and thumbail test..

Cordialement..

Re: Oops!!

Posted: 25 May 2013, 20:15

by smnbyt

No probs, I shall have a rumage tomorrow

Simon

Re: Oops!!

Posted: 25 May 2013, 21:47

by Plasticman

i sense a tig moment approaching,zzzzzzzzzzzzzzzzzzz crackle zzzzzzzzzzz

mm

Re: Oops!!

Posted: 26 May 2013, 14:53

by smnbyt

Right, I've found it. If you let me have your email address I can send some pictures of it

Simon

Re: Oops!!

Posted: 26 May 2013, 17:24

by sarran1955

smnbyt wrote:Right, I've found it. If you let me have your email address I can send some pictures of it

Simon

Hello,

You have PM

Cordialement,

Re: Oops!!

Posted: 26 May 2013, 17:29

by AdrianC

metalmick8y wrote:i sense a tig moment approaching,zzzzzzzzzzzzzzzzzzz crackle zzzzzzzzzzz

There's two people I can think of on 80-90 who could glue that back together... Mickey & John. Walk in the park!

Re: Oops!!

Posted: 26 May 2013, 18:42

by sarran1955

Hello,

Thank you for all the interest..

Bearing in mind the proximity of the cracked parts to the line of the cam bearings..

I'm getting a copper bar machined to be clamped in the housings to act as a heat sink..

and a sleeve to go into the bolt hole.

However.. as I want to put in as little heat as possible, considering the angle of attack and that I will have to build up some long beads.

I will go for MIG welding, using Argon/Helium mix, and a magnesium/ silicone rich aluminium welding wire...

I will grind back to sound metal using a diamond air tool to avoid contamination...

All this has to be ordered in the week...

from the UK..... because it is so much cheaper...

Cordialement,

Re: Oops!!

Posted: 26 May 2013, 20:32

by tobydog

Laser welding's good for getting down holes, though expensive.

http://www.carrswelding.co.uk/classic_p ... icles.html" onclick="window.open(this.href);return false;

Re: Oops!!

Posted: 28 May 2013, 17:57

by sarran1955

Hello,

Thanks for the link.......(drool Icon)..

Compare the heat inputs on the table below..

http://www.carrswelding.co.uk/why_laser_welding.html" onclick="window.open(this.href);return false;

This is why I would use a 'foundation' of tig, then build up in MIG.

The decision on whether to weld or go second hand will be price determined this week..

Keep you posted..

Cordialement,

Re: Oops!!

Posted: 02 Jun 2013, 17:44

by sarran1955

Hello,

Well I've had a busy sunday....

So here is the case that has been prepped to take the 'splints'

Here are the made up inserts with aligning bolt

The inserts are tack welded in

Then a good penetrating run down either side..

All the excess is ground off and prepared for the second pass with this air tool

Then 'building up' with more metal..

Clean again and look for' pinholes and shorts'

Check that the bolt moves freely in the new thread..

Here is the case split apart again with the weld being smoothed to take out any stresses..

The case now nipped up and the oil strainer and bottom plate in place... torqued up..

and going to be left a couple of days....

Now to start work on the cylinder heads....

Cordialement,