Page 7 of 24

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 10:25

by Ciaraneng

For anyone doing this and reusing push rods I'd recommend an overnight soak in kerosene. The jar in the foreground contains the gunk that came out after an external clean and an overnight soak.

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 10:27

by 937carrera

Some nice clean parts there

On the stud, remove the stud and replace it, remember aluminium expands faster than steel as well so some heat is your friend

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 10:54

by itchyfeet

yes oil travels up push rods from the hydraulic lifter and so I guess they would get full of crap, good tip, never done it myself but I will in future.

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 12:07

by Ciaraneng

Thanks Carrera/Itchy.

Another question: Do new hydraulic lifters/tappets need to be bled or are they done in the factory? I got mine from BW.

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 12:13

by itchyfeet

Ciaraneng wrote:Thanks Carrera/Itchy.

Another question: Do new hydraulic lifters/tappets need to be bled or are they done in the factory? I got mine from BW.

They come dry, or at least with just a film of oil, you have to take them apart one by one, fill with oil, and bleed to get the circlip back in. Store in a bath of oil until you need them.

Then fit and do the valve adjustment, 2 turns normally after touching.

It's all in Haynes but the Brickwerks supplied KS tappets are a slightly different design to those shown in Haynes, same principle though.

Also highly recommended to use assembly lube inside the tappet to help them bed in and use Camshield with ZDDP when you first run the engine.

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 15:16

by Ciaraneng

itchyfeet wrote:Also highly recommended to use assembly lube inside the tappet to help them bed in and use Camshield with ZDDP when you first run the engine.

Thanks Itchy. Sorry, when you say to 'use assembly lube inside the tappet' what do you mean?

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 16:42

by itchyfeet

Something like this, take it all apart, fill the tappet with oil and coat the plunger/piston with assembly lube and insert them, the lube is sticky and it's formulation helps the parts to bed in.

also coat tappets before inserting into bores.

https://www.ebay.co.uk/itm/Race-Engine- ... 3039357071" onclick="window.open(this.href);return false;

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 18:27

by Ciaraneng

Re: Rebuild Thread (Probably)

Posted: 16 Feb 2019, 21:35

by Ciaraneng

Re: Rebuild Thread (Probably)

Posted: 17 Feb 2019, 07:21

by ajsimmo

itchyfeet wrote:

also coat tappets before inserting into bores.

This is good advice, but I now just coat sides with assembly lube, and a dab of camshield zinc paste on the flat end that runs on the cam. Best practice & all that

Sent from my ONEPLUS A3003 using Tapatalk

Re: Rebuild Thread (Probably)

Posted: 17 Feb 2019, 07:29

by ajsimmo

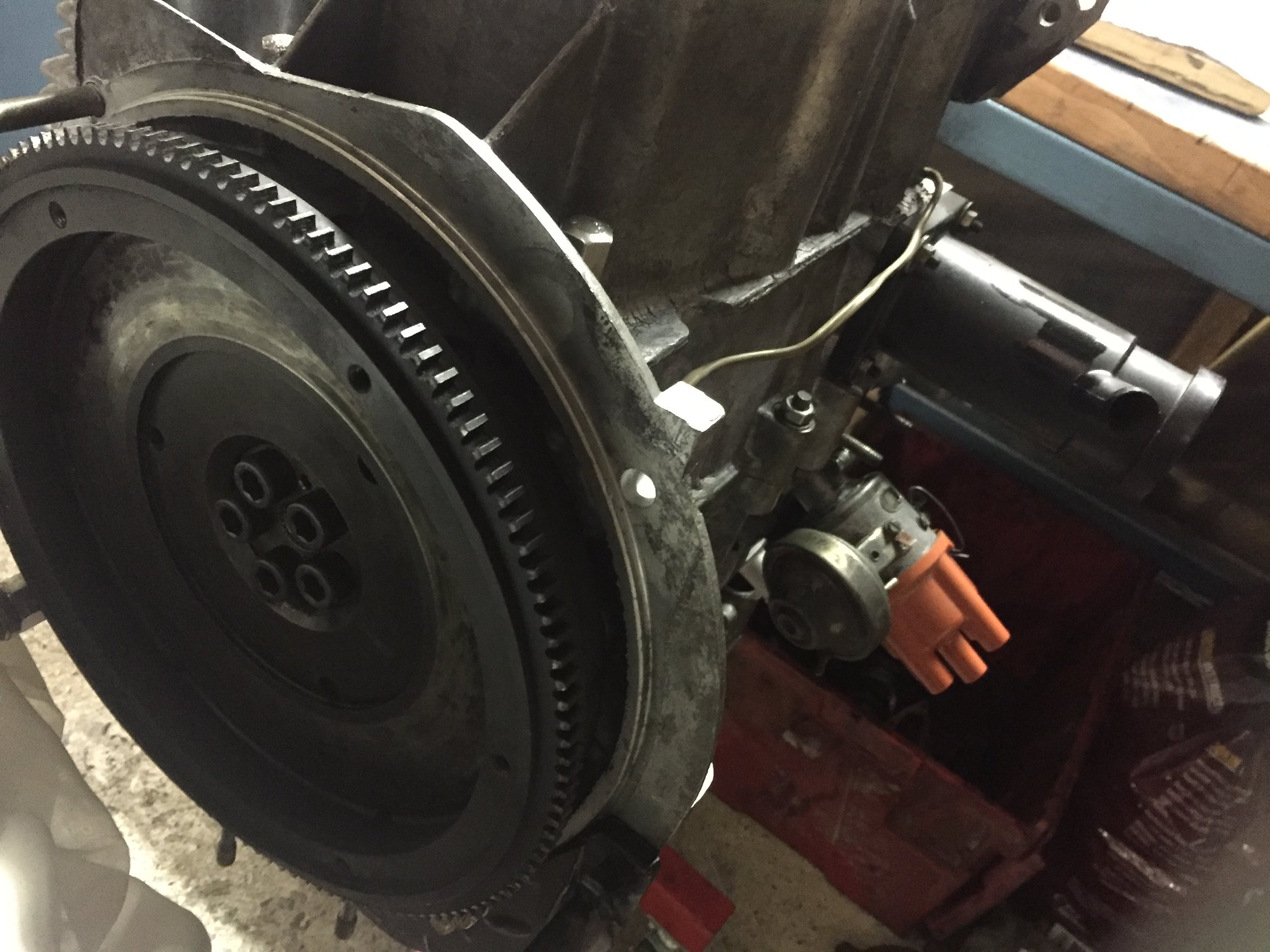

I'd be very concerned about the state of the sealing edge of that case. Dirko will fill small pitting, but this is a bit big to rely on that...

Sent from my ONEPLUS A3003 using Tapatalk

Re: Rebuild Thread (Probably)

Posted: 17 Feb 2019, 11:48

by Ciaraneng

ajsimmo wrote:I'd be very concerned about the state of the sealing edge of that case. Dirko will fill small pitting, but this is a bit big to rely on that..

Thanks Andrew, I have limited options as the case is the best of the two. It's not as deep as it looks in the photos and the rebuilder I used said it was just about OK. I might use some JB weld and sand it back.

Re: Rebuild Thread (Probably)

Posted: 17 Feb 2019, 23:30

by Ciaraneng

Re: Rebuild Thread (Probably)

Posted: 18 Feb 2019, 00:03

by 937carrera

Coming on nicely , it seems as though it's throwing itself back together

Re: Rebuild Thread (Probably)

Posted: 18 Feb 2019, 08:11

by ajsimmo

Nice bead of sealant there on the water jacket seal - not put on with a trowel like some I see! Good work. Were you twitching at the 50Nm stage?

Sent from my ONEPLUS A3003 using Tapatalk