Page 7 of 30

Re: WBXlog

Posted: 03 Nov 2016, 10:36

by ajsimmo

itchyfeet wrote:He said don't get involved fixing otter peoples vans if they aren't paying

"Have you fixed my van yet?"

Re: WBXlog

Posted: 03 Nov 2016, 10:37

by ajsimmo

Re: WBXlog

Posted: 05 Nov 2016, 14:41

by ajsimmo

No...? Nobody?

I'll get my coat.

Re: WBXlog

Posted: 06 Nov 2016, 16:53

by itchyfeet

Back to the thread

Finished the other engine reseal today so the DJ is back on the hydraulic table

Pistons ready, rings have arrived so crack on with that tomorrow.

https://club8090.co.uk/forum/viewtopic.p ... 3#p8163832" onclick="window.open(this.href);return false;

P1060230

P1060230 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 07 Nov 2016, 08:03

by ajsimmo

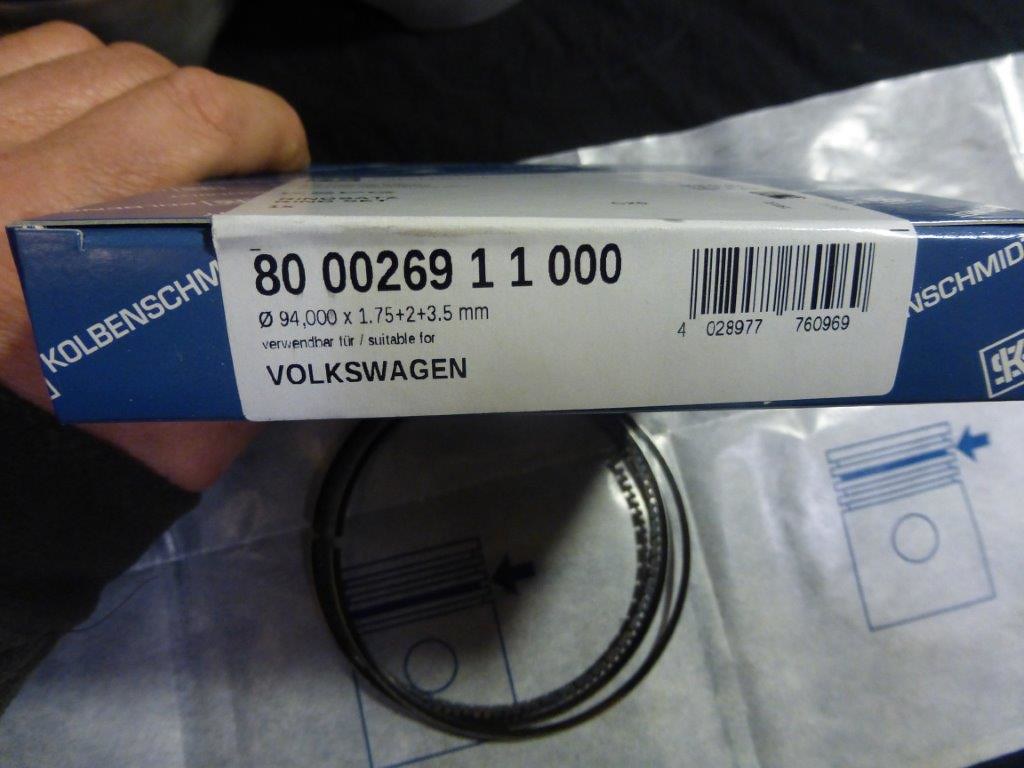

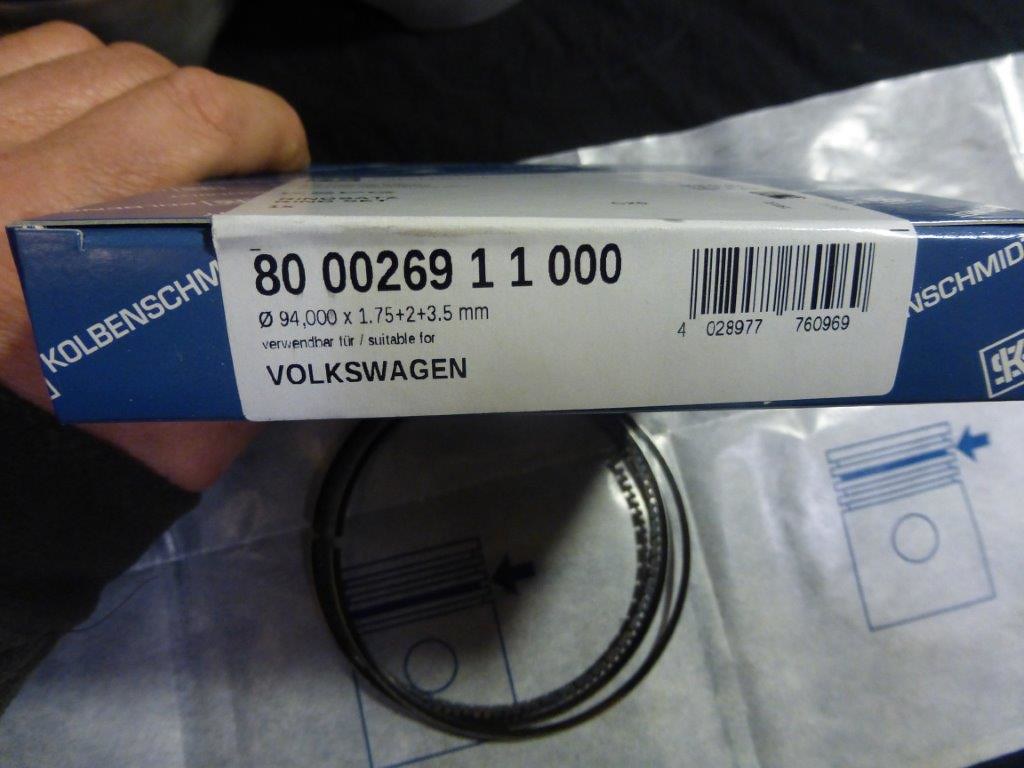

Which ring set have you gone for? I expect BW KS, but just in case...

Just found that the VWH set is not Bosch (as advertised) but Grant's standard set without the chrome top ring. No good to me then! Also they state they fit DJ and MV, yet Grant's listing states different sets with different oil ring - 3.5mm for DJ / 4mm MV (same as DG).

I'll be measuring my piston stash later.

Re: WBXlog

Posted: 07 Nov 2016, 08:50

by itchyfeet

Interesting, thanks for the heads up

I will measure too.

I noticed when removing the old rings the top ring was different from DG heavy spring to it very hard to get off by hand and hard to break too ( wanted a bit to clean grooves out) , had to stretch it way open before it broke.

got these as you suspected

https://www.brickwerks.co.uk/t3-parts/e ... iston.html" onclick="window.open(this.href);return false;

ajsimmo wrote:

I'll be measuring my piston stash later.

I suspect that may take some time

Re: WBXlog

Posted: 07 Nov 2016, 10:21

by ajsimmo

Lol thankfully I didn't have to do them all!

Results are....

Grant's spec sheet is wrong, VWH are right! Nominal 3.5mm groove on MV & DJ, 4.0mm on DG.

Sent from my GT-I9305 using Tapatalk

Re: WBXlog

Posted: 07 Nov 2016, 19:40

by itchyfeet

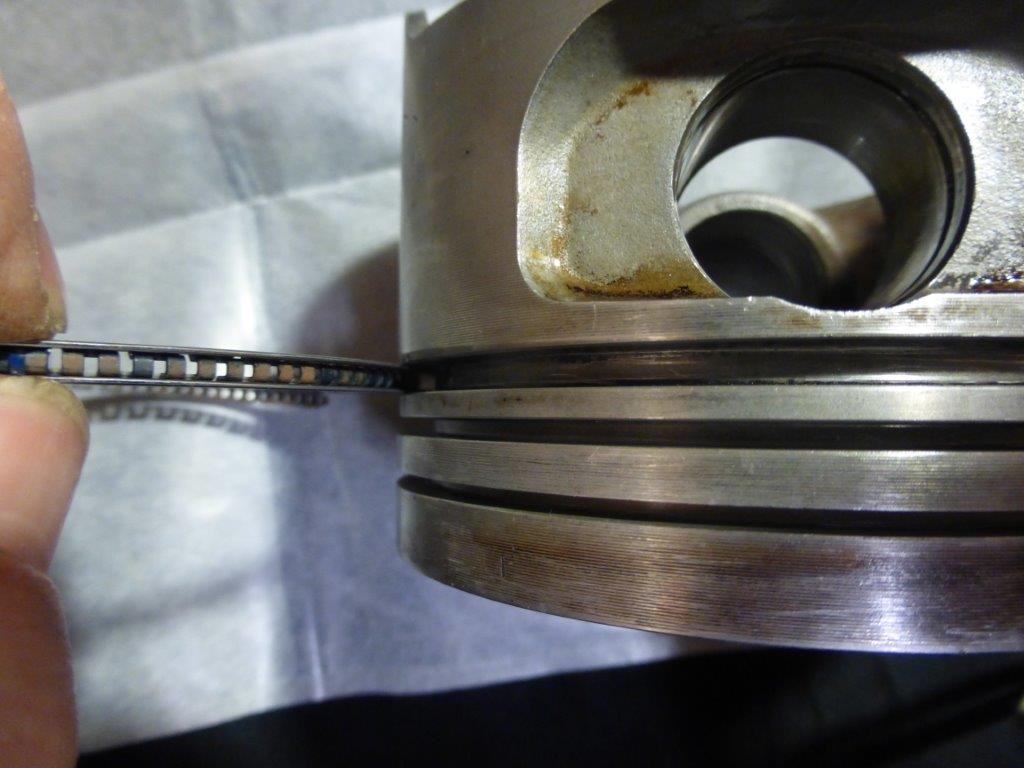

Gudgeons are all very tight in these pistons, looks like they were hammered out, VW had problems with burrs on the pistons so made a reamer tool but most of us don't have them so have to hammer pins out

I used the 24mm reamer to loosen them up, not too much but just enough to be able to get them through by hand.

P1060231

P1060231 by

Paul_Barr, on Flickr

P1060232

P1060232 by

Paul_Barr, on Flickr

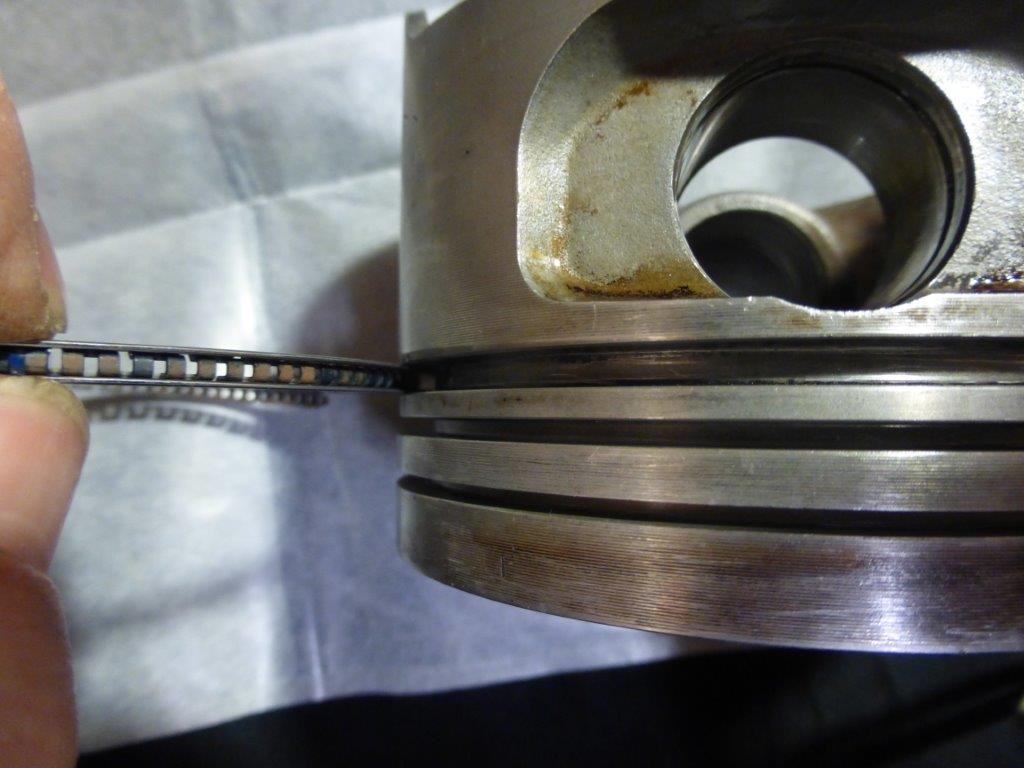

Cleaned out ring grooves with an old broken ring, middle ring grove was particularly dirty.

Cleaned the oil holes with a 2.5mm drill

P1060233

P1060233 by

Paul_Barr, on Flickr

Cleaned any dirt of the outside with 1200 wet and dry then blasted them with carb cleaner to get any swarf and debris off ( don't get it in your eye it hurts

)

P1060235

P1060235 by

Paul_Barr, on Flickr

Matched biggest most worn barrel with biggest least worn piston, max allowed is 0.2mm

1 94.04/93.97 = 0.07mm

2 94.02/93.96 = 0.06mm

3 94.02/93.92 = 0.04mm

4 94.06/93.97 = 0.09mm

P1060236

P1060236 by

Paul_Barr, on Flickr

These are the rings from Brickwerks

P1060252

P1060252 by

Paul_Barr, on Flickr

wasn't expecting the oil control ring to look like this

(old one removed on the left which looks like the DG ones I just fitted but 3.5mm wide)

P1060243

P1060243 by

Paul_Barr, on Flickr

Must fit like this, job for tomorrow.

P1060248

P1060248 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 08 Nov 2016, 07:45

by itchyfeet

itchyfeet wrote: otter peoples vans

Get it now

Re: WBXlog

Posted: 08 Nov 2016, 19:47

by itchyfeet

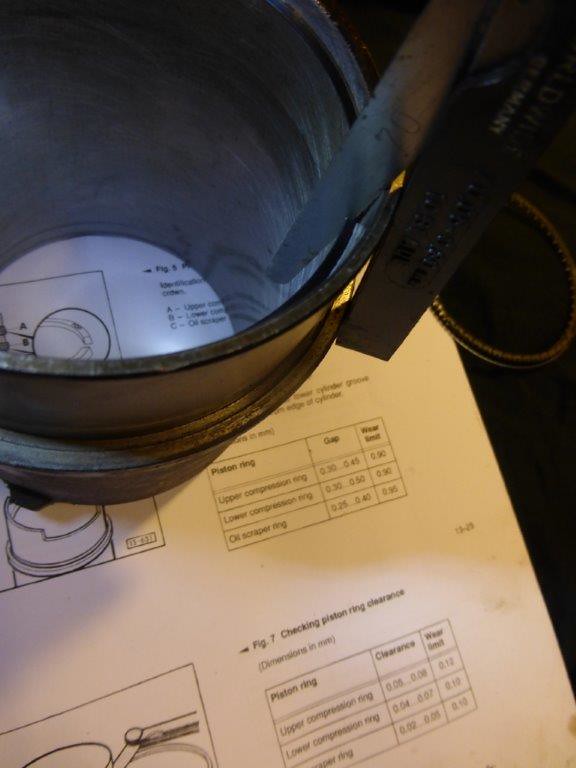

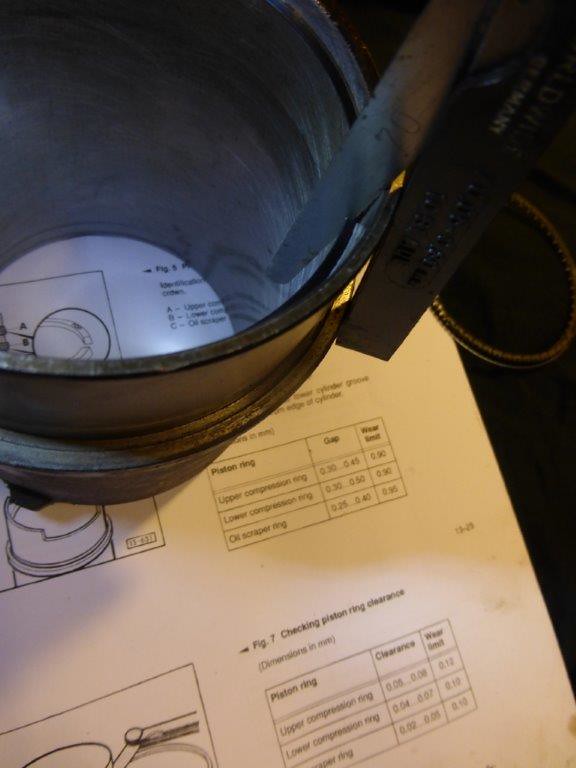

Measured ring gaps tonight ( been here before with the DG pistons), all a bit higher than I'd liked even with the virtually standard size barrel but still within wear limit spec of 0.9 or 0.95mm, these rings must be smaller than the original VW. Oil scraper and middle ring 0.7mm, top ring 0.6mm

P1060254

P1060254 by

Paul_Barr, on Flickr

important to get the pistons and barrels arranged so rings go on the right way up, oil control and top compression gaps always up which means 1&2 are different to 3&4, centre rings always down, arrows always to flywheel.

P1060263

P1060263 by

Paul_Barr, on Flickr

Oil control rings went on easily but I got the idea of staggering them, can't see any good reason not to and would help I assume, can't see then staying aligned anyway

P1060265

P1060265 by

Paul_Barr, on Flickr

No way could I got the top ring on by hand, much stiffer than the DG, had to get the expander tool on it.

P1060266

P1060266 by

Paul_Barr, on Flickr

finally checked ring groove wear, all Ok and within spec.

P1060273

P1060273 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 09 Nov 2016, 08:27

by ajsimmo

itchyfeet wrote:itchyfeet wrote: otter peoples vans

Get it now

Lmao. How long did you stare at it......!?

Re: WBXlog

Posted: 09 Nov 2016, 09:17

by what2do

ajsimmo wrote:itchyfeet wrote:itchyfeet wrote: otter peoples vans

Get it now

Lmao. How long did you stare at it......!?

Doesn't matter what he looks at these days, all he sees is wbx components!

Re: WBXlog

Posted: 09 Nov 2016, 10:18

by itchyfeet

ajsimmo wrote:

Lmao. How long did you stare at it......!?

Kept thinking head seal

Re: WBXlog

Posted: 09 Nov 2016, 10:22

by marlinowner

My advice would be to keep beavering away.

Re: WBXlog

Posted: 09 Nov 2016, 13:12

by itchyfeet

what2do wrote:

Doesn't matter what he looks at these days, all he sees is wbx components!

Waterboxer

P1060230 by Paul_Barr, on Flickr

P1060230 by Paul_Barr, on Flickr P1060231 by Paul_Barr, on Flickr

P1060231 by Paul_Barr, on Flickr P1060232 by Paul_Barr, on Flickr

P1060232 by Paul_Barr, on Flickr P1060233 by Paul_Barr, on Flickr

P1060233 by Paul_Barr, on Flickr P1060235 by Paul_Barr, on Flickr

P1060235 by Paul_Barr, on Flickr P1060236 by Paul_Barr, on Flickr

P1060236 by Paul_Barr, on Flickr P1060252 by Paul_Barr, on Flickr

P1060252 by Paul_Barr, on Flickr P1060243 by Paul_Barr, on Flickr

P1060243 by Paul_Barr, on Flickr P1060248 by Paul_Barr, on Flickr

P1060248 by Paul_Barr, on Flickr P1060254 by Paul_Barr, on Flickr

P1060254 by Paul_Barr, on Flickr P1060263 by Paul_Barr, on Flickr

P1060263 by Paul_Barr, on Flickr P1060265 by Paul_Barr, on Flickr

P1060265 by Paul_Barr, on Flickr P1060266 by Paul_Barr, on Flickr

P1060266 by Paul_Barr, on Flickr P1060273 by Paul_Barr, on Flickr

P1060273 by Paul_Barr, on Flickr