Thanks for the pointers on case sealing - it is now sealed up.

The build back up wasn't too painful in the end, become a pro at getting the circlips in and out (not sure its a transferable skill for my CV!)

Next step was to get the flywheel on, which meant getting the engine in the van out (I only have the one flywheel, as one I bought had a flex plate for an auto on it). This is mentioned in the WIKI, but without a photo, so here is a photo of propping the gearbox on a bit of wood whilst dropping the engine - very secure, very stable and frees up jacks/axle stands for other things. I can also confirm it leaves the box at the right angle for easy re installation:

Note the wood isn’t supported by the axle stands, although it looks like it is in this shot.

Engine out and sat in the corner:

Now fitting the flywheel was a pain – the engine stand got in the way, so I rigged up a homemade ‘crane’:

Not that elegant, but it gave me the space to get the flywheel on and set the end float.

Now as I don’t have a dial gauge a bit of inventiveness was required to set the end float, so assembled this:

All done up tight so nice and solid, wind in bolt so its close, measure, then lever flywheel and measure again, end float is the difference. Simples!

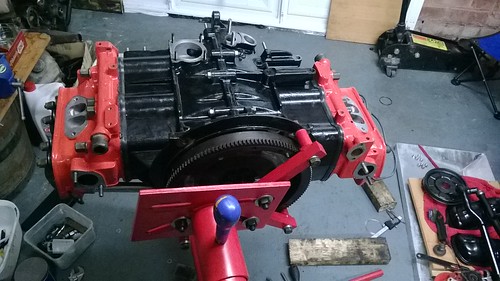

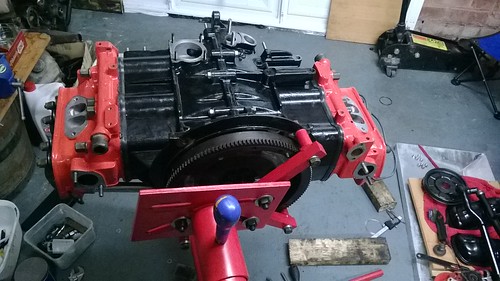

Shim, seal, o-ring, little felt pad and spigot bearing in and flywheel done up, back on engine stand:

Only now the engine won’t turn over, as the flywheel rests on the engine stand however I arrange the supports. What a pain, as it means I can’t set the dizzy drive up or sort out the hydraulic tappet preloads. So, now I know what the shims need to be I’ll have to take the flywheel back off, and refit at the end! One step forward, one step back at the moment....

On the up side the new dizzy arrived (went for a vw heritage one, although it looks surprisingly like the ebay one that VWKat popped up – I was hoping it would be better for the money!?) Makes me realise quite how knackered the old one was!!

Cheers,

Alex