Page 4 of 11

Re: Tight viscous coupling

Posted: 13 Jan 2011, 22:22

by v-lux

Nice PDF!

This is the bit that really sets the VC apart from other systems for me:

The speed difference dependent torque

transfer redistributes driveline torque to the

wheel or axle with the better traction

Re: Tight viscous coupling

Posted: 13 Jan 2011, 22:52

by jed the spread

Jed

Re: Tight viscous coupling

Posted: 14 Jan 2011, 09:01

by silverbullet

That pdf says it all. An end to the mythology and clearly explained. Well found Clive

Now about that fill percentage...

Re: Tight viscous coupling

Posted: 14 Jan 2011, 09:20

by syncrosimon

So hump mode is achieved by the fluids thermal expansion causing the axially movable inner plates to be pushed into the outer plates, the friction causing drive.

Nice find Clive, wonder if GKN will be doing refurbed VC's any time soon.

Re: Tight viscous coupling

Posted: 14 Jan 2011, 09:59

by silverbullet

So that finally clears up the business of worn and distorted plates. They are definitely a wearing part and aren't just a flat perforated/slotted disc but have surface relief features too...

It's been a long while to find this out, has a patent expired so they can finally spill the beans, I wonder?

Re: Tight viscous coupling

Posted: 14 Jan 2011, 11:26

by HarryMann

It's been a long while to find this out, has a patent expired so they can finally spill the beans, I wonder?

Have actually been saying this for as long as I've had the SAE papers by various researchers, at least four or five years ago. And also trying to dispel this

invented myth below...

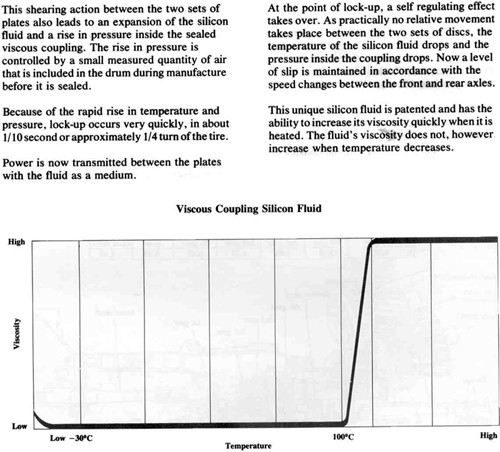

Shall have to ask Steve to remove that from Syncro.org or re-label the y-axis, because it manifestly is

not viscosity

But don't assume that Rolt or FFD knew the actual mechanism, Prof . Wolfgang Peschke* 1986 and then others, figured out the major design parameters and subsequently a pretty good mathematical model of operation and specifically hump mode reversion was produced by the early 90's.

Or that a patent needs to fully describe a modus operandi, it doesn't, it could be unknown but still 'written around'

It certainly is not straightforward.

*SAE Technical Paper 860386,

A Viscous Coupling in the Drive Train of An All-Wheel-Drive Vehicle,

1986, Wolfgang Peschke - Volkswagenwerk AG:

Re: Tight viscous coupling

Posted: 14 Jan 2011, 12:11

by silverbullet

Myths and legends, magycke and wychecrafte, here be monsters etc

A few people with a vested interest to keep it under wraps, more who have convinced themselves (wrongly) that it works in a given way, the rest muttering "that's going to be expensive to fix..." and accept that you can't always understand everything, even though you want to.

The y-axis is more like transmitted torque (or rate of change thereof), if anything?

Re: Tight viscous coupling

Posted: 14 Jan 2011, 13:10

by syncropaddy

syncrosimon wrote:So hump mode is achieved by the fluids thermal expansion causing the axially movable inner plates to be pushed into the outer plates, the friction causing drive.

I knew that! This explains more fully the phenomena of the 'lock up' sometimes experienced after a long motorway drive when you pull into services and you get scuffing when you turn the steering wheel. The silicone has heated up and the unit has gone into hump mode. This only happens in some VC units which would suggest that the fluid fill parameters were not met. So how hot does the silicone have to get before hump mode happens? What happens if this temperature continues to rise? Is the scuffing phenomena experienced when cold caused by the friction in the silicone because the temperature too low?

Re: Tight viscous coupling

Posted: 14 Jan 2011, 15:37

by HarryMann

No Andrew, it can't lock in hump mode really, and of course the beauty is the natural feedback system, as soon as it locks, it cools, and comes out of lock, so the mechanism is one of rapid cycling, holding the device at a nominal torque to lock sufficiently - almost self-regulating.

Hump temps, from 150C up to 220C depending on air-void, viscosity and plate design. Max pressures up to 100 bar.

Hump-mode is known in the literature as STA (Self-induced Torque Amplification) - what else would you call it after all

The last and best paper I have found is circa 2004, by S. K. Mohan of New Venture Gear Inc. (who co-authored an earlier paper in 1992, No. 920611, which failed to produce a complete description, prediction & model of the STA process)

This proposes a complete mathematical model covering the complete mechanism for most plate designs (slotted & perforated) and STA onset prediction

SAE Technical Paper Series 2004-01-0867 - A Comprehensive Theory of Viscous Coupling Operation - Sankkar K. Mohan

(reprinted from : Transmission & Driveline Symposium 2004 (SP-1817)

Re: Tight viscous coupling

Posted: 14 Jan 2011, 15:40

by HarryMann

Now its got me thinking, if anyone has experimented with using pure Nitrogen or others for the void gas, to prolong life, removing the oxygen form the equation as with modern tyre filling?

It's probably such a small quantity its insignificant...

probably

Re: Tight viscous coupling

Posted: 14 Jan 2011, 21:23

by MoonlightCustoms

to go back to the first question why use a decoupler if a working vc doesnt start to put power to the front till the rear slips if theres no slip on the motor way theres no drive to the front. Also how does a decoupler save wear to the front, the drive shafts and diff etc are still turned by the front wheels are they not.

Or have i missed to point?

Re: Tight viscous coupling

Posted: 14 Jan 2011, 22:40

by syncrosimon

The decoupler makes the Syncro a more complete and enjoyable vehicle to drive. It also makes it easier to service and gives you the option of having a more aggressive VC which performs better off road. There is no way that I would consider 3500 mile trips without one. My experience of owning a 2 1/2 year old Syncro is that the VC tightens up on the motorway when you just don't need it working.

It's a personal choice thing, I use my syncro 95% on the road, and just don't use the 4x4. The front driveshafts on mine have done 45,000 miles and I have never removed them, partly due to the fact that there is no strain going through them, they are just gently polishing themselves.

People seem very bitter about the decoupler, which is a bit of a mystery. I am personally sure that VW left the wiring in place in the syncro on all models upto 1992 as an insurance against having to retro fit it in case the VC had unexpected long term issues. It turns out that it is a wear item like a clutch, and having a decoupler would mean that the VC is no longer a wear item, and would last almost indefinitely. Why wear something out when you are not even using it, it just does not make mechanical sense.

Re: Tight viscous coupling

Posted: 14 Jan 2011, 23:17

by ..lee..

Suppose it doesn't help it's surrounded by super hot oil. I wonder how much effect that has on the vc. If your Tyres are correct then vc slip on the motorways should be minimal. So, it the oil heating up effecting the vc's. I'd guess yes.

Re: Tight viscous coupling

Posted: 14 Jan 2011, 23:43

by syncropaddy

MoonlightCustoms wrote:to go back to the first question why use a decoupler if a working vc doesnt start to put power to the front till the rear slips if theres no slip on the motor way theres no drive to the front. Also how does a decoupler save wear to the front, the drive shafts and diff etc are still turned by the front wheels are they not.

Or have i missed to point?

You are correct in what you say and no you havent missed the point. People who have bought de couplers will always tell you how great they are because they have just spent a load of money on a 'gadget' so they dont want to look like a numpty and tell you it makes no difference. People will tell you things like

"I use my syncro 95% on the road, and just don't use the 4x4. The front driveshafts on mine have done 45,000 miles and I have never removed them, partly due to the fact that there is no strain going through them" when they have a de coupler - well I dont have a de coupler and I can say that I use my syncro 95% on the road, and just don't use the 4x4 either cuz I have a VC. The front driveshafts on mine have done 285,000kms and I have never removed them, partly due to the fact that there is no strain going through them because I have a VC that works! The VC is a wear item like most stuff on cars and thats how manufacturers make money by selling new ones!

syncrosimon wrote:I am personally sure that VW left the wiring in place in the syncro on all models up to 1992 as an insurance against having to retro fit it in case the VC had unexpected long term issues.

WHAT???? Why would they have to retro fit two bits of wire? Its cheaper to leave two bits of wire on the loom than take it out - any production engineer will tell you that. Modifications on parts that are homologated cost too much money

Re: Tight viscous coupling

Posted: 14 Jan 2011, 23:57

by HarryMann

to go back to the first question why use a decoupler if a working vc doesnt start to put power to the front till the rear slips if theres no slip on the motor way theres no drive to the front.

There is always some small torque transmitted forwards due to the device's static frictional torque, measurements of 25~50 Nm have been made. Then the rears may also be slipping fractionally, maybe 1 or 2% in a straight line at speed, especially on wet road.

What's maybe not appreciated fully is the speed of action and self-regulating nature. It really shouldn't be getting near over-heating and locking on a Motorway.

Much of what Simon says is true I'm sure.

I don't think the diff oil is necessarily overheating the VC itself, but maybe there is a problem with the radiator airflow and overall diff temperature. It wouldn't be too hard to fit some sort of oil circulation and cooling device, or modify the airflow somewhat.

Don't forget that diff oil (at the right nominal temperature) is also a cooling and equilibrating medium, bringing the VC case back down to oil temp more rapidly than air itself would.