Page 27 of 30

Re: WBXlog

Posted: 23 Jul 2018, 17:48

by itchyfeet

937carrera wrote:I was meaning a taper thread form tap.:

Do they exist, if they do I will buy one but my point is I can't find them?

Re: WBXlog

Posted: 23 Jul 2018, 17:56

by ghost123uk

ghost123uk wrote:Ford oil pressure switches were like that [tapered into straight thread] (X-Flow engines etc). You used to just screw them in pretty tight, with a bit of red Hermatite on the thread.

Ignore me then

Re: WBXlog

Posted: 23 Jul 2018, 18:08

by itchyfeet

ghost123uk wrote:ghost123uk wrote:Ford oil pressure switches were like that [tapered into straight thread] (X-Flow engines etc). You used to just screw them in pretty tight, with a bit of red Hermatite on the thread.

Ignore me then

yeh I heard you John but were they metric taper form?

maybe they were NPT threads which are a taper form, this is about an M10x1 taper form and the tap to match?

Re: WBXlog

Posted: 23 Jul 2018, 18:17

by ghost123uk

Ah no, I just meant the taper thread into parallel hole principle, not the actual thread / device in question

It just reminded me of ages faffing around on a Ford X-Flow once, when fitting a "T" piece to add a OP gauge. Lots of fun with threads a sealing there was

Carry on, ignore me, I'm waffling

Re: WBXlog

Posted: 23 Jul 2018, 18:50

by itchyfeet

ghost123uk wrote:Ah no, I just meant the taper thread into parallel hole principle

Oh I see thanks.

Re: WBXlog

Posted: 23 Jul 2018, 18:52

by itchyfeet

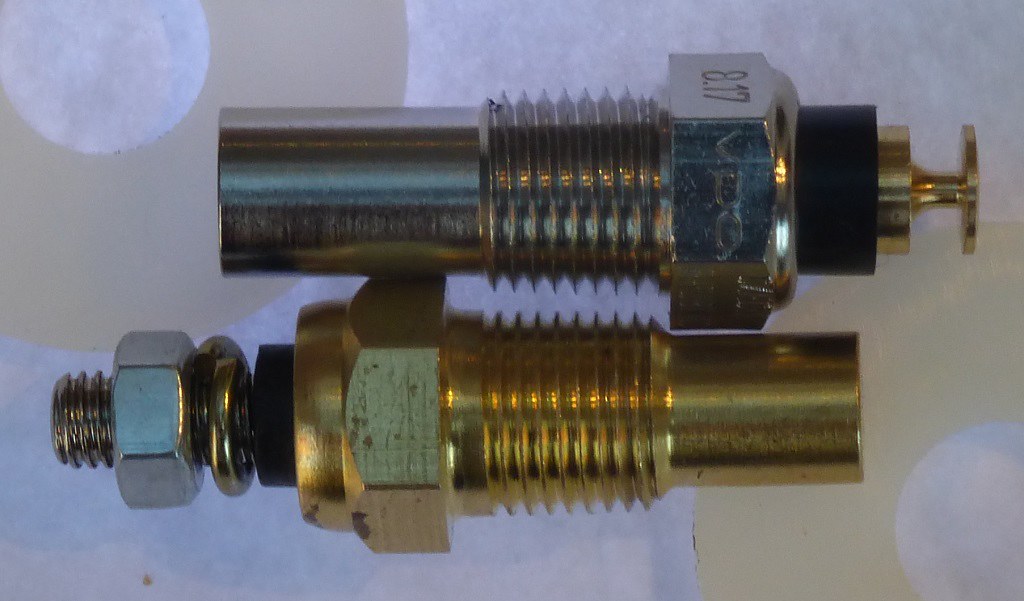

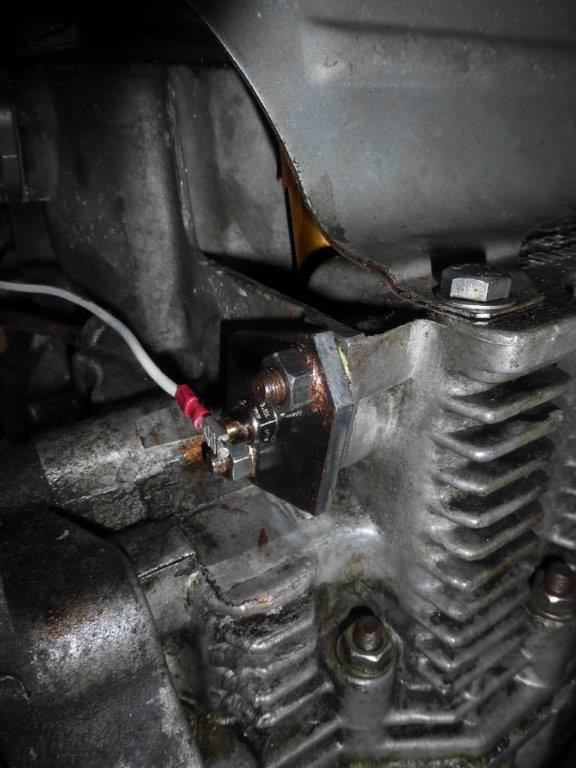

Just compared with a 1/8 NPT sender/sensor to rule that out and the thread is very similar but pitch slightly different, had to zoom in form a distance to be rid of the parallax.

P1100507

P1100507 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 23 Jul 2018, 18:59

by itchyfeet

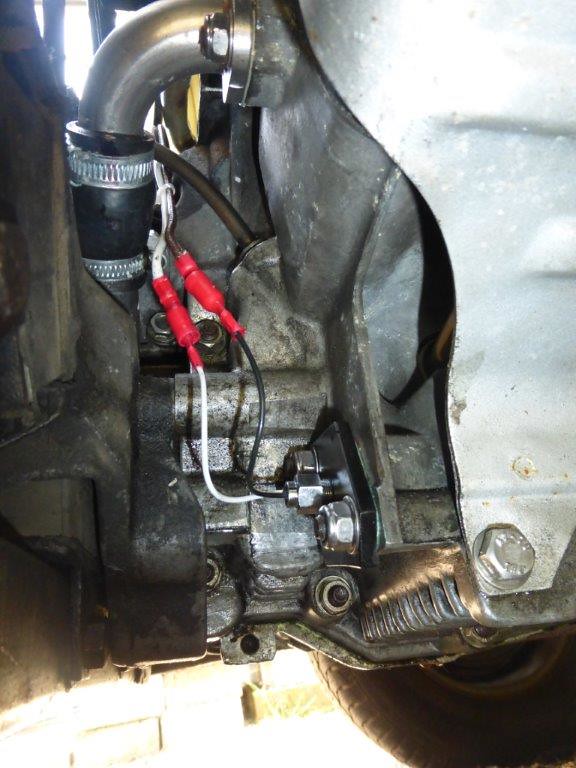

and to prove there is nothing wrong with my M10x1 tapping skills

P1100508

P1100508 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 23 Jul 2018, 19:26

by 937carrera

itchyfeet wrote:937carrera wrote:I was meaning a taper thread form tap.:

Do they exist, if they do I will buy one but my point is I can't find them?

Definitely available in the hydraulic world, but they will be NPT or similar rather than metric.

I went for a google and found this

https://www.practicalmachinist.com/vb/g ... ad-237609/

Looks like you're ok

Re: WBXlog

Posted: 23 Jul 2018, 19:57

by itchyfeet

Thanks I had a skim and missed the bit where it said it was all OK

I know there are NPT threads it's what I have currently with my elcheapo gauge sender/sensor and the current plate tapped with an NPT taper tap

I just didn't expect to see a taper M10x1 from VDO when there is no mention of it anywhere I can find.

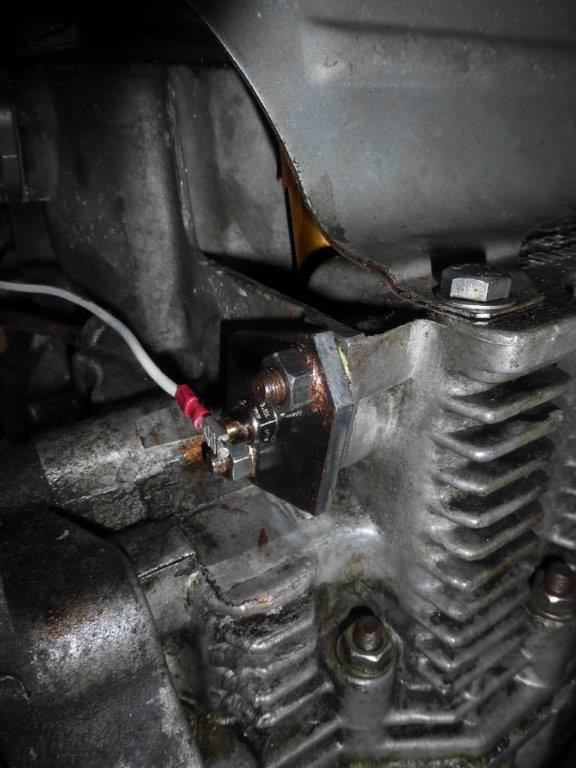

P1100346

P1100346 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 23 Jul 2018, 20:01

by itchyfeet

ohhh here it is from your link DIN158-1

https://www.gewinde-normen.de/en/metric ... n-158.html" onclick="window.open(this.href);return false;

According to DIN 158-1, only the external thread is conical, the internal thread is cylindrical.

Re: WBXlog

Posted: 24 Jul 2018, 08:30

by tobydog

From the Festo website:

The following rules must be adhered to when using a combination of G and R-threads: Male G-threads (cylindrical) can only be screwed into female G-threads. Male R-threads (conical) can be screwed into female G or R-threads.

PS

Tapered female threads are a pain in the %$^& to tap

Re: WBXlog

Posted: 24 Jul 2018, 09:02

by itchyfeet

tobydog wrote:From the Festo website:

The following rules must be adhered to when using a combination of G and R-threads: Male G-threads (cylindrical) can only be screwed into female G-threads. Male R-threads (conical) can be screwed into female G or R-threads.

PS

Tapered female threads are a pain in the %$^& to tap

thanks

yes I know female tapers are hard to.tap

I ruined a few plates when I was using the 1/8 NPT tap

I discovered you need to go really slow barely a shaving before backing off and going again

lots of cutting paste and regular tap cleaning

Re: WBXlog

Posted: 24 Jul 2018, 12:07

by ghost123uk

tobydog wrote:Male R-threads (conical) can be screwed into female G or R-threads.

Told you so

Re: WBXlog

Posted: 24 Jul 2018, 18:23

by itchyfeet

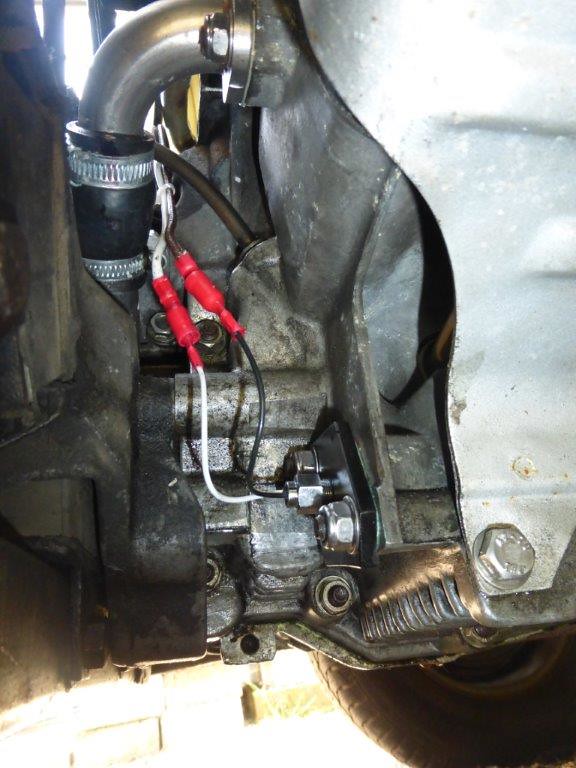

Fitted it tonight and ran it up to fan cutting in and out, there was a bit of a delay from oil temp to gauge rising as before due to thermal lag of the engine case but the reading was far more accurate much quicker.

Within 5 degrees isn't bad and no leaks, a longer test drive would give a better understanding, it maybe that the guge would rise further in time towards real sump oil temperature.

Not sure the M10x1 conical thread would seal as well if you used it again, there was clearly some thread deformation happening as a bit of swarf popped out, maybe I should not have screwed it in so far but I'm not planning to remove it from the plate.

P1100512

P1100512 by

Paul_Barr, on Flickr

P1100517

P1100517 by

Paul_Barr, on Flickr

boiling kettle for reference

P1100520

P1100520 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 25 Jul 2018, 09:17

by bigbadbob76

That looks better Paul.

Following with interest.

P1100346 by Paul_Barr, on Flickr

P1100346 by Paul_Barr, on Flickr P1100512 by Paul_Barr, on Flickr

P1100512 by Paul_Barr, on Flickr P1100517 by Paul_Barr, on Flickr

P1100517 by Paul_Barr, on Flickr P1100520 by Paul_Barr, on Flickr

P1100520 by Paul_Barr, on Flickr