Page 20 of 30

Re: WBXlog

Posted: 18 Feb 2017, 08:34

by itchyfeet

tobydog wrote:Itchy, the groove should ideally be in the bore so that the o seal doesn't travel past the hole on assembly

Try giving the oil hole entrance a generous rad.

yep but thats not how others have done, I didn't invent this mod just following in footsteps with an information vacuum.

Doing the case means you could only do this mod on a rebuild and it would take a milling machine, modding the pump means anybody can do it.

it goes in OK it's passing the oilways thats the problem a generous rad will eat into the very small flat sealing area but I will add a bit more. I don't think you need a seal for +5 bar you need a seal for maybe - 1 bar ( a guess) at the inlet to stop air sucking in so less seal compression I think is the answer.

Re: WBXlog

Posted: 20 Feb 2017, 18:26

by itchyfeet

cut the o ring groove 1.5mm deep today ( it was 1.4), it was much easier to fit but still damaged the oring

P1080002

P1080002 by

Paul_Barr, on Flickr

So then I realised I'd concentrated on smoothing the back edge of the oil hole in the block and it may well be cutting on the way out, so a bit more work all around.

P1080005

P1080005 by

Paul_Barr, on Flickr

and it now goes in and out without damage, still needs tapping in with a block of wood

P1080003

P1080003 by

Paul_Barr, on Flickr

P1080012

P1080012 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 20 Feb 2017, 20:54

by tobydog

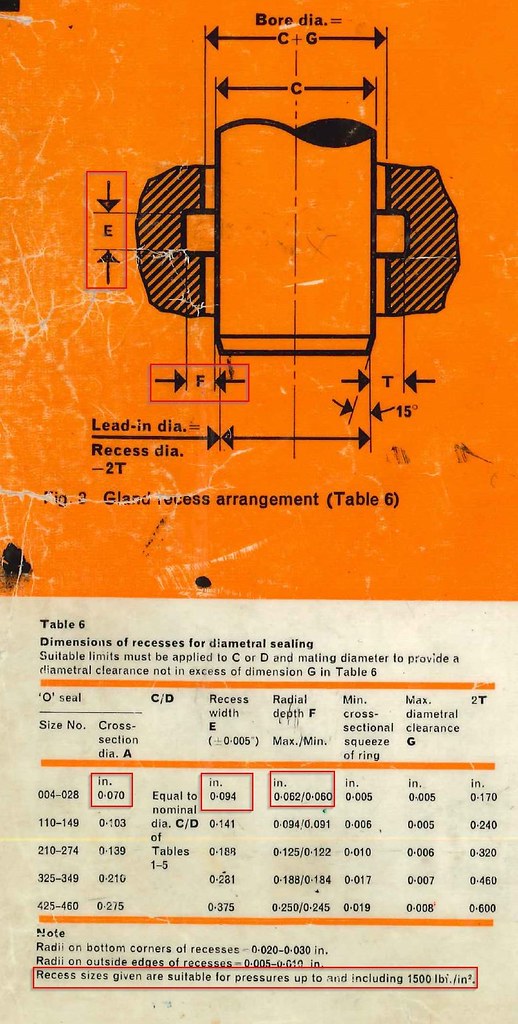

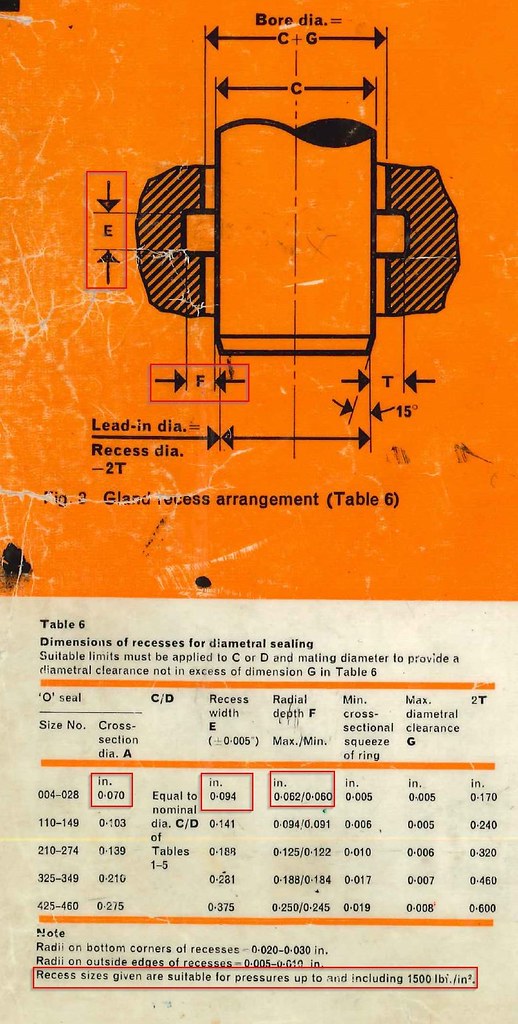

Itchy, BS 036, 0.070" section (imperial series) grooves can be 1.57mm (0.062") deep in the application your using. What's the diameter of the bore?

Found out what your doing the hard way nearly 40 years ago designing injection moulds, when you have 64 bores that need radiusing, boss, toolmaker etc. get the hump.

Re: WBXlog

Posted: 20 Feb 2017, 21:02

by itchyfeet

Thanks, Pump is 70mm diameter and crankcase is not much bigger.

Re: WBXlog

Posted: 20 Feb 2017, 21:24

by tobydog

Should be a BS038 (2.75"), as your doing, you can get away with stretching them on.

Re: WBXlog

Posted: 20 Feb 2017, 21:33

by itchyfeet

tobydog wrote:Should be a BS038 (2.75"), as your doing, you can get away with stretching them on.

2.75 is bigger isn't it ?

Re: WBXlog

Posted: 20 Feb 2017, 22:53

by tobydog

PM

Re: WBXlog

Posted: 27 Feb 2017, 10:45

by itchyfeet

Thanks for the o ring catalogue Mick

finally got around to reading it and it looks like my dims are pretty close to this

says good for 1500psi so I'd think I could open it up a bit more and still be fine for 5 bar

bs_o-seals

bs_o-seals by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 27 Feb 2017, 20:26

by weimarbus

Watching with interest, for what it's worth I have just taken apart an older 'rebuilt' MV with an original VW oil pump and there is no staining or any sign of oil being drawn in between pump and crankcase ie shiny aluminium all around the oil pump intake, maybe aftermarket pumps are not such a close tolerance

Re: WBXlog

Posted: 27 Feb 2017, 20:41

by itchyfeet

^^^I think thats exactly it, pump tolerances used to be better, or at least that's what I read.

Having said that you may not see any marking from air being drawn in.

I have stalled on this for the moment, got to do my wishbone bushes first.

400 miles on the DJ rebuild so far, not used a drop of coolant and very little oil, no tappet noise, great to drive, had it up to 80 at the weekend, very pleased with it

Re: WBXlog

Posted: 27 Feb 2017, 22:47

by 300CE

Glad the DJ is running well Paul, a testament to all that hard work mate

Re: WBXlog

Posted: 04 Mar 2017, 19:41

by itchyfeet

Thanks Justin.

Bought some new 3.5mm vac hose from Brickwerks for the DJ as it was old and tired, went to fit it today and the dizzy moved, forgot to tighten it 400 miles ago

Re: WBXlog

Posted: 05 Mar 2017, 10:29

by 300CE

itchyfeet wrote:Thanks Justin.

Bought some new 3.5mm vac hose from Brickwerks for the DJ as it was old and tired, went to fit it today and the dizzy moved, forgot to tighten it 400 miles ago

Oops! Well if it hasn't been running lumpy at different speeds mate, I'm sure any movement has been minimal.

Re: WBXlog

Posted: 15 Mar 2017, 13:35

by itchyfeet

A comment on the fb WBX page I though was worth sharing and recording here

Marco Mansi wrote:I dont recommend dirko-s for the case halves , but if you have used it and closed it up right away you will be fine, i now use loctite SI 5900 for the case halves, as thats what ive been using on the watercooled Porsche's for 10 years and never had one problem or one leak whatsoever, with the Curl-T after 5 years of daily use it will start to seep oil, it doesn't matter how good the rebuild is or how perfect it runs if it leaks one drop of oil its a terrible engine rebuild according to the Porsche world

The SI 5900 smells and acts just like dirko-s but is just slightly thinner

Just turned 500 miles on the DJ build

Re: WBXlog

Posted: 15 Mar 2017, 16:37

by weimarbus

itchyfeet wrote:A comment on the fb WBX page I though was worth sharing and recording here

Marco Mansi wrote:I dont recommend dirko-s for the case halves , but if you have used it and closed it up right away you will be fine, i now use loctite SI 5900 for the case halves, as thats what ive been using on the watercooled Porsche's for 10 years and never had one problem or one leak whatsoever, with the Curl-T after 5 years of daily use it will start to seep oil, it doesn't matter how good the rebuild is or how perfect it runs if it leaks one drop of oil its a terrible engine rebuild according to the Porsche world

The SI 5900 smells and acts just like dirko-s but is just slightly thinner

Just turned 500 miles on the DJ build

Good news on the DJ, time for an oil change? Just had a package from Germany with some shiney new KS DJ pistons and the pile of new bits is getting bigger in a seemingly indirect relation to the hole in my bank account

Re crankcase sealant, I've always had good results with red Hermitite (now Hylomar)

Try giving the oil hole entrance a generous rad.