Page 19 of 30

Re: WBXlog

Posted: 22 Jan 2017, 21:02

by itchyfeet

Just standard acrylic spray paint over vactan for rust.

None of it gets too hot.

Re: WBXlog

Posted: 22 Jan 2017, 21:33

by dumbo

cheers mate

Re: WBXlog

Posted: 09 Feb 2017, 18:48

by itchyfeet

Just a progress report, engine is going great, did 200 miles around A and B roads which means about 55 mph max probably about 3000 rpm max maybe a bit more when I forgot to change gear

Then after asking some advice on fb I was told time to give it some beans so last weekend I did about another 80 miles doing just that, took it down the M27 for a bit slowing to 60 then hard acceleration to 70 and repeat, there are some steep hills so did one full chat, had it past 70 up the hill, lots of A and B roads too done without a care for fuel consumption

Re: WBXlog

Posted: 09 Feb 2017, 20:45

by sarran1955

Hello,

There ya go....

You put 20/50 mineral diesel oil at the next change..

and be happy with at least 1.4 bar on hot tickover..

if it don't clatter..don't fix it..

Don't forget to retorque the heads cold soon..

Cordialement,

Re: WBXlog

Posted: 09 Feb 2017, 21:03

by itchyfeet

sarran1955 wrote:

Don't forget to retorque the heads cold soon..

Never heard of retorquing WBX heads, you could do the nuts one at a time but you would need to remove, clean and reseal them with yellow sealant or hymolar as they form the water jacket seal.

Talking of oil pressure I'd like to learn empirically what helps on the oil pump before going 2050, options are o rings, 30mm pump as well as paper gasket or no gasket.

Have you started the 'new project' or are you still off skiing, sorry I mean sick with that thumb

Re: WBXlog

Posted: 09 Feb 2017, 22:44

by ajsimmo

sarran1955 wrote:

You put 20/50 mineral diesel oil at the next change..

Don't forget to retorque the heads cold soon..

I'm guessing the wink means these are tongue in cheek...maybe air-cooled humour (which, perhaps, I have yet to master)?

But just in case, engine oils formulated for diesels is a bit too detergent for this job IMHO, and you're right about re-torquing as it would break the sealant, so each nut would need removing, cleaning and new sealant applied. An exercise in futility (and carries a degree of risk!).

Re: WBXlog

Posted: 10 Feb 2017, 15:41

by itchyfeet

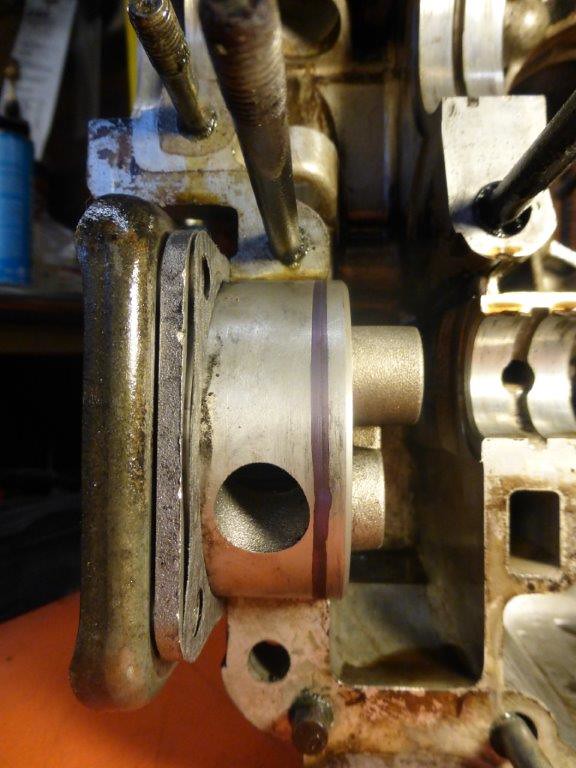

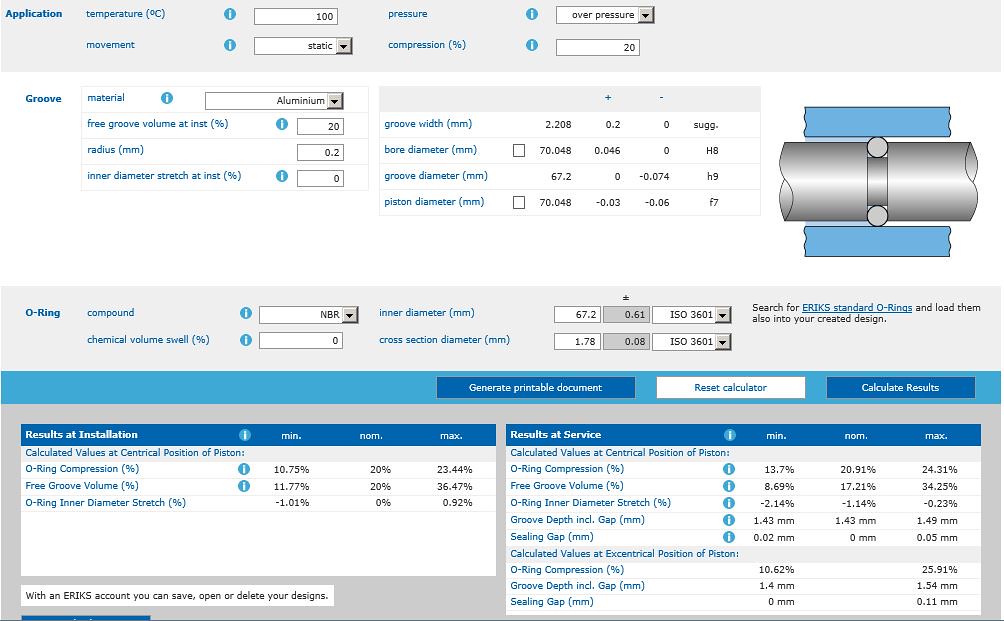

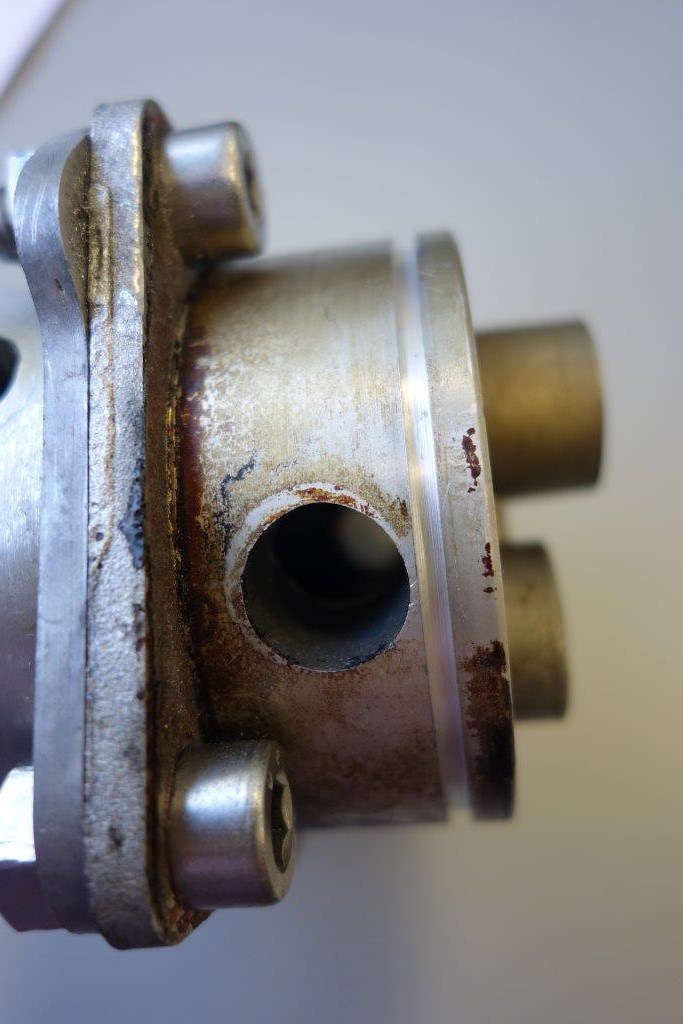

I want to try the o ringed oil pump mod but details are sketchy on exact dims and rings.

The mod is to fit at least one oring so that when the pump is pushed into the case it is sealed around the bore.

The difference on bore to pump diameter means the input and output of the pump can leak.

From what I gather some air can be sucked in from sump as the path of least resistance, easier than sucking oil from the sump via the oil strainer and pipe, this airates the oil and as we know with brakes air in the system lowers pressure, you can also loose pressure from the pump output back to sump.

the o ring would need to be very roughly where marker pen line is but there is very little land so it must precise.

P1060967

P1060967 by

Paul_Barr, on Flickr

The oil pump cover gasket is another issue, all gaskets ars above the 0.1mm allowed endfloat, we can only guess what VW had in mind, my opinion is the end float measurement is independent of gasket, so 0.1mm is alloed then add gasket ( 0.16 ish for a VW gasket) so effectively meaning you get 0.26mm float total when fitted which is a nice round one thou. We know thinner gaskets are better and the latest thinking is leave them out and use curil T.

So back to the o rings, one minimum and leave the pump to case gasket in place but you could do two and omit pump to case gasket, I'm not bothered about that at this stage.

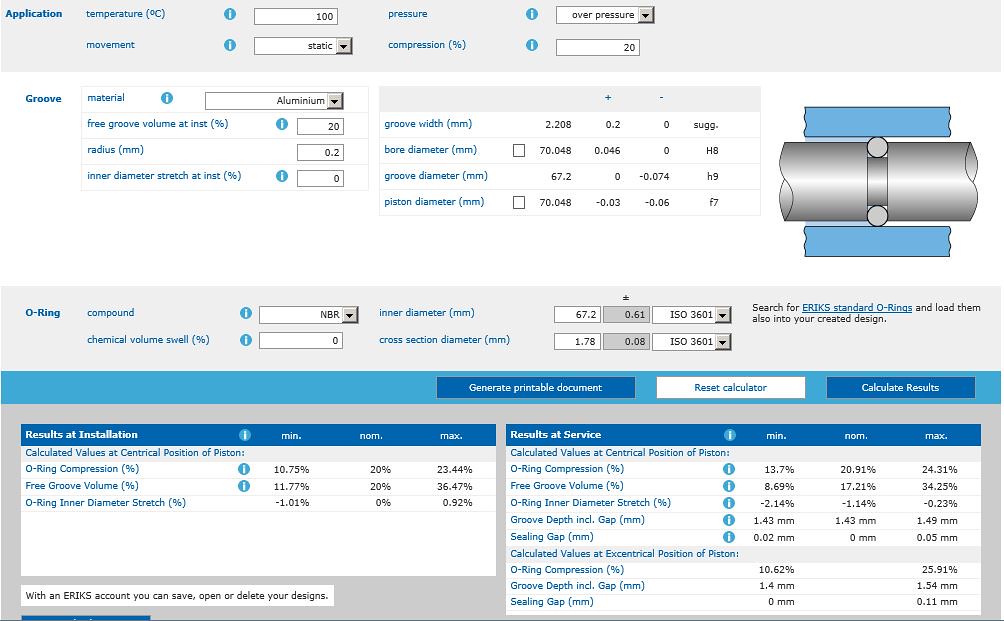

I have done some work on this and I think the solution is 66.4 IDx1.78 dia o ring and stretch it a bit, you would need Viton good for 200 deg C available for pennies here

https://www.polymax.co.uk/o-rings/rubbe ... s050-viton" onclick="window.open(this.href);return false;

Using Eriks Calculator you are looking at a groove 2.2mm wide and 1.4mm deep ( or ID 67.2) for 20% nominal compression, this assumes the case is pretty much bang on 70mm diameter as the pump is.

Oil pump oring

Oil pump oring by

Paul_Barr, on Flickr

Next I have to try and hold the pump in a lathe, I bolted another old pump to it and using a dial gauge centered the pump to be turned.

I have ordered a parting off tool 3/32" 2.4mm, width is not so important as groove depth which dictates compression ( rubbish phone pic)

20170210_080516

20170210_080516 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 10 Feb 2017, 19:17

by sarran1955

Hello,

itchyfeet wrote:sarran1955 wrote:

Don't forget to retorque the heads cold soon..

Never heard of retorquing WBX heads, you could do the nuts one at a time but you would need to remove, clean and reseal them with yellow sealant or hymolar as they form the water jacket seal.

Talking of oil pressure I'd like to learn empirically what helps on the oil pump before going 2050, options are o rings, 30mm pump as well as paper gasket or no gasket.

Have you started the 'new project' or are you still off skiing, sorry I mean sick with that thumb

Darn.. you spotted the Aircooled..(no goop).. joke..

Seriously, stop worrying about the oil pressure..

run a 20 /50 mineral..'the stuff' came from Morris (?) of Shrewsbury many years ago..

I only said HD because that is what we have delivered 1 tonne at a time..

and I bet you'll find at 1000km, you tickover at 1.6bar.

all that happens if you go no gasket is you 'swirl' marks into the outer cover for max 3% gain..

New project... bliddy crank is a 69 mm..need same journals as early df, but in dg throw.. max 74 mm to fit the CT case.

.. then Porsche 356 con rods.'A' pin pistons.. AA products 500 heads..

Ski ing.. now that the tempest 'Gabriel' has passed..

Thumb.. stitches out today..10 more days off..

Waiting for Eberspacher power electronics..just my luck..time off and its the Chinese New Year.

Cordialement,

Re: WBXlog

Posted: 10 Feb 2017, 19:59

by itchyfeet

sarran1955 wrote:Hello,

New project... bliddy crank is a 69 mm..need same journals as early df, but in dg throw.. max 74 mm to fit the CT case.

.. then Porsche 356 con rods.'A' pin pistons.. AA products 500 heads..

Didn't understand a word, pics needed, have an early DG case you can have if it helps, perhaps cut water jacket off, got broken studs though ?

Thumb.. stitches out today..10 more days off..

crack on with the homers then

Not worrying about oil pressure anymore, this is a learning experience

Re: WBXlog

Posted: 11 Feb 2017, 10:49

by weimarbus

good idea to bolt the pumps together for turning. I look forward to seeing the results of your labour re oil pressure, especially as you have taken the time to record all the prior pressures, it will be good to see what differences can be achieved. Are you planning on using the 30mm pump?

Re: WBXlog

Posted: 11 Feb 2017, 11:45

by itchyfeet

weimarbus wrote:good idea to bolt the pumps together for turning. I look forward to seeing the results of your labour re oil pressure, especially as you have taken the time to record all the prior pressures, it will be good to see what differences can be achieved. Are you planning on using the 30mm pump?

I'm leaning towards changing one thing at a time in the interests of learning and because everybody tells me this pressure is good enough I'm in no hurry.

My old DG had low pressure due to a blown cam bearing and worn big ends so no amount of testing would yield any meanigful results, here I have a good understanding of condition inside so it will give me a better indication of what helps, so O ring old pump first I think.

another thing I could try is reducing endfloat by taking material off front of pump on a sheet of wet and dry, it has between 0.05 and 0.1 at the moment.

then 30mm pump if these mods don't push up pressure.

Re: WBXlog

Posted: 13 Feb 2017, 13:01

by itchyfeet

Parting off tool arrived today, it's undersize at 2.2mm, perfect

Forgot to order the orings next job

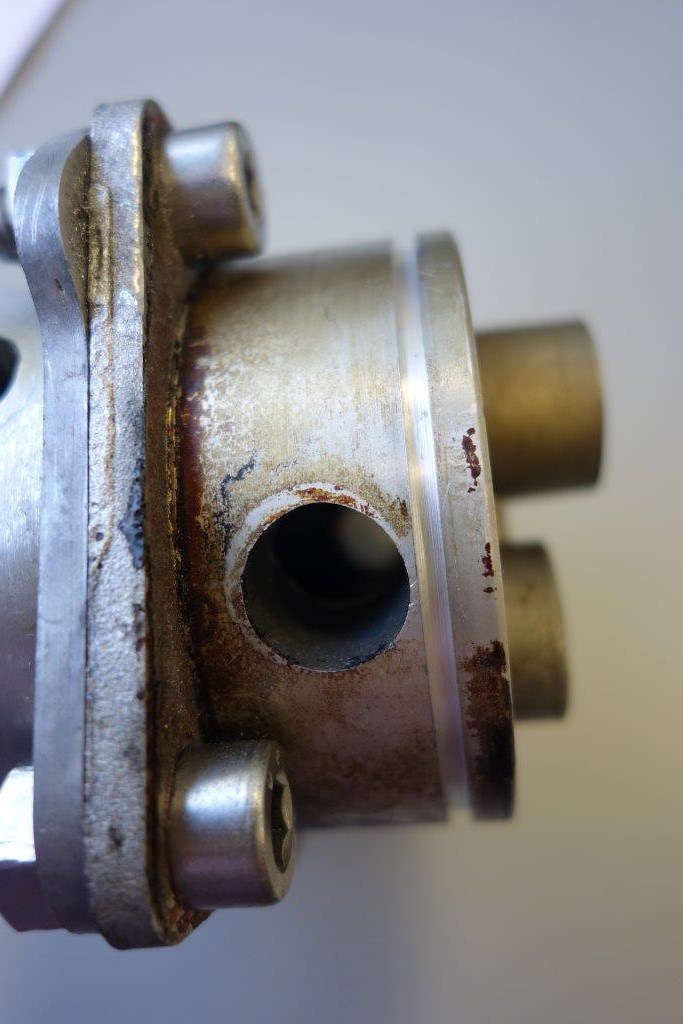

Interesting that the pump outlets are larger than inlets and they are not all the same, the pump machined has a 14mm outlet but the VW pump I have has a 16mm outlet which means there is very little space left for an oring on the VW pump.

DSC01820

DSC01820 by

Paul_Barr, on Flickr

DSC01827

DSC01827 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 16 Feb 2017, 18:17

by itchyfeet

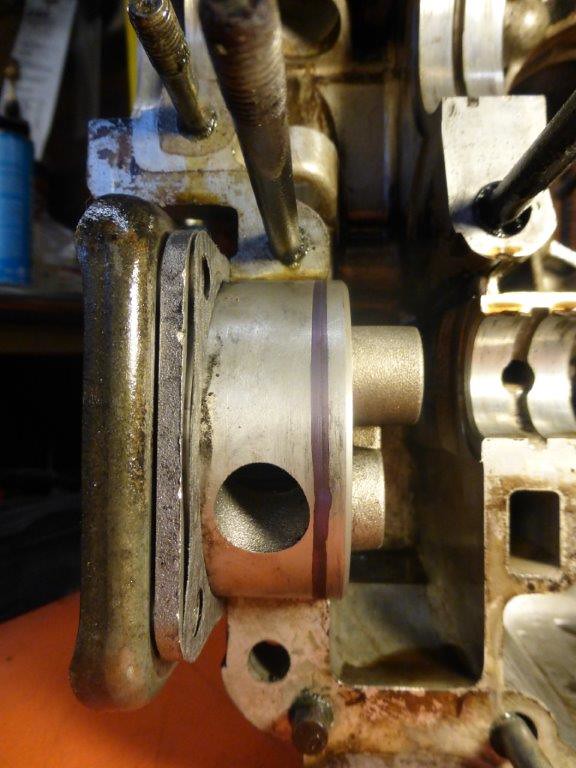

O rings arrived today, there was a £10 min order from the company in the link so I ended up with 50.

Anybody want to try this and has actually cut a groove I will send you some.

fits well

P1060990

P1060990 by

Paul_Barr, on Flickr

this shows how little space there is

P1060991

P1060991 by

Paul_Barr, on Flickr

bolted the two case half together to see how it fits, I would expect to give it a bit of encouragement with a piece of wood and a hammer but it was a bit too much of a thump with a lump hammer for my liking

Before making the groove deeper I think I will give the edge of the crankcase hole a small chamfer to help lead it in.

P1060992

P1060992 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 17 Feb 2017, 17:50

by itchyfeet

Smoothed off the tiny chamfer that was on the block and took the sharp edge of the oil channels ( inserted a piece of cloth when doing this to stop anything going in) but it's still cutting the O ring and still needs hammering in ( retrieved the o ring bit with tweezers)

So too much o ring compression, need to recalculate and make the slot deeper, shore hardness of 75 so probaly does not need much compression, job for next week in a lunchtime

3 down 47 o rings to go

P1060996

P1060996 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 17 Feb 2017, 22:49

by tobydog

Itchy, the groove should ideally be in the bore so that the o seal doesn't travel past the hole on assembly

Try giving the oil hole entrance a generous rad.

P1060967 by Paul_Barr, on Flickr

P1060967 by Paul_Barr, on Flickr Oil pump oring by Paul_Barr, on Flickr

Oil pump oring by Paul_Barr, on Flickr 20170210_080516 by Paul_Barr, on Flickr

20170210_080516 by Paul_Barr, on Flickr

DSC01820 by Paul_Barr, on Flickr

DSC01820 by Paul_Barr, on Flickr DSC01827 by Paul_Barr, on Flickr

DSC01827 by Paul_Barr, on Flickr P1060990 by Paul_Barr, on Flickr

P1060990 by Paul_Barr, on Flickr P1060991 by Paul_Barr, on Flickr

P1060991 by Paul_Barr, on Flickr P1060992 by Paul_Barr, on Flickr

P1060992 by Paul_Barr, on Flickr P1060996 by Paul_Barr, on Flickr

P1060996 by Paul_Barr, on Flickr