Page 15 of 49

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 18 Jun 2017, 22:51

by CJH

itchyfeet wrote:Are you 100% sure they are all 8mm?

My mistake - I removed an exhaust valve and measured it. It is indeed 9mm, apart from the very top section where the collets sit. So from your question I'm guessing the good people on FB all told you there aren't any 8mm exhaust valves. Did they explain why the AMC ones are cheese (what's wrong with them), and what they'd use instead?

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 19 Jun 2017, 05:58

by itchyfeet

The end with collets wears out

Trying to find a pic but fb search is not on my tablet

Marco Mansi ( builds turbocharged wbx for bug drag racing so knows his stuff) says he uses

Gieffe.it

Origional VW valves will work if you have some old heads

Brickwerks stock TRW they are said to be good

It's no coincidence that Brickwerks stock the AMC head bare

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 19 Jun 2017, 06:09

by CJH

Thank you - I'll look into those options.

I'd be interested to see that photo - it's not obvious to me why that end would wear.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 19 Jun 2017, 07:09

by ajsimmo

Found it. Except I heard (can't remember where or from whom) that AMC were aware of the problem several years ago, and had addressed it. I could be wrong, as it's only hearsay.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 19 Jun 2017, 07:10

by ajsimmo

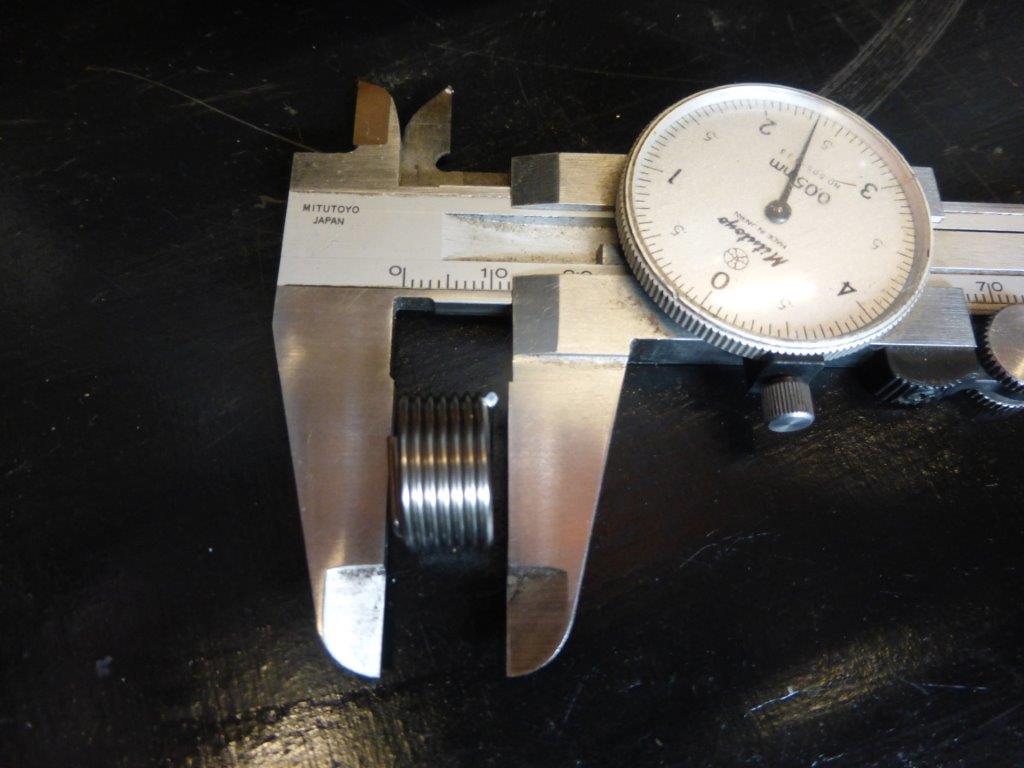

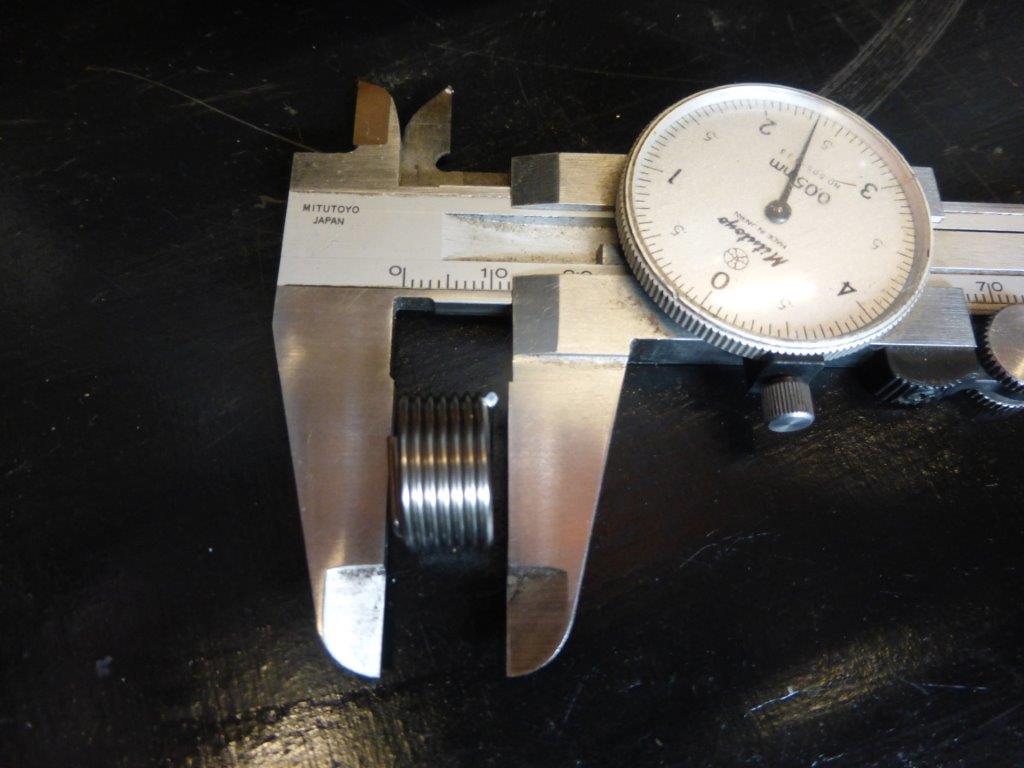

Marco Mansi: Just to show, this is a set of stock AMC heads with the intake valve about to fail, people usually only replace the exhaust in the AMC's but almost all the AMC heads I've rebuilt have problems with the intake. Comparison next to a typical but still worn valve

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 19 Jun 2017, 07:14

by ajsimmo

And another.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 19 Jun 2017, 09:02

by itchyfeet

AMC addressed it by selling heads bare

Marco said yesterday they are still cheese

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 19 Jun 2017, 16:10

by CJH

OK, well those photos are compelling enough. My first and only engine rebuild prior to this one was 30 years ago on a Triumph 1500 engine that dropped a valve. I wonder what sort of mileage it takes for these cheese valves to get like that.

After a quick search I can't find a supplier for the Gieffe valves (3057IN and 3058EX I think) other than in Russia, and given the competitive pricing of Brickwerks' TRW valves I guess that's what I'll go for.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 24 Jun 2017, 10:24

by CJH

I was checking over a few things prior to final assembly, and I've discovered that my sump thread needs repair. Only the outer two or three turns are intact, and although it'll hold a sump plug I'm not confident that it will take the torque, or last. So seeing how it's a lot easier to deal with this on the bench I'm planning to helicoil it. I want to retain the M14 thread because I plan to use this sump plug oil temperature sender.

I've fitted helicoils before, but only ever to a 'blind' hole. Since the sump thread is obviously a 'through' hole, I'm wondering if there's a danger that the insert could wind it's way out of the hole when removing or refitting the sump plug. Winding out I can cope with, but winding in would be a bit of a disaster during a future oil change. Is it worth smearing a thin layer of joint sealing compound (I'm using Loctite SI 5900 as per a report from FB via Itchyfeet) onto the aluminium sump threads prior to winding the insert in, just to help 'glue' it in place?

I recall another post (also from Itchyfeet I think) showing a length of pipe being used to guarantee the insert goes in perpendicular, and I've sorted out a short length of square-cut 22mm copper pipe to help with that. I'm also alert to making sure the insert isn't too long - ideally it needs to not protrude into the sump, so that oil and gunge can drain out properly, and obviously it needs to be below the plug sealing face. Both of those constraints mean that there's nothing to prevent it from winding in or out, hence the question above.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 24 Jun 2017, 10:46

by itchyfeet

It will only wind in by the tang which slightly reduces its size ( imagine twisting a spring)

one the tang is snapped off it will stay

had helicol in mine for years

WBXlog showns the length needed

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 24 Jun 2017, 16:25

by CJH

Thank you, that makes sense. I know you'll tell me it's not necessary, but for good measure I guess I've also got the option to not cut the thread all the way through, maybe leaving one turn uncut, so that the insert couldn't wind in any further. I'd need to make sure that I don't push the insert so far that it starts to bind up where there's no thread, meaning the sump plug would not get past that point, but that should be quite easy to control on the bench.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 24 Jun 2017, 16:45

by itchyfeet

CJH wrote:Thank you, that makes sense. I know you'll tell me it's not necessary, but for good measure I guess I've also got the option to not cut the thread all the way through, maybe leaving one turn uncut, so that the insert couldn't wind in any further. I'd need to make sure that I don't push the insert so far that it starts to bind up where there's no thread, meaning the sump plug would not get past that point, but that should be quite easy to control on the bench.

you are over complicating it, it's really not a problem

1D M14x1.5 Helicoil (1D 1x Diameter in length)

I cut one turn off the helicoil by inserting a washer, and using a dremmel cutting disc. The cut is clean enough to use without any deburring.

P1050432

P1050432 by

Paul_Barr, on Flickr

P1050437

P1050437 by

Paul_Barr, on Flickr

P1050440

P1050440 by

Paul_Barr, on Flickr

tang snapped off easily with pliers

P1050442

P1050442 by

Paul_Barr, on Flickr

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 24 Jun 2017, 16:54

by CJH

itchyfeet wrote:

you are over complicating it, it's really not a problem

See - I said you'd say that (or similar). In case my explanation wasn't clear, keep in mind that I haven't yet tapped out the thread in the sump (helicoil kit is arriving next week), so if I don't cut it all the way through, then the last, say, 1mm of the sump will physically stop the insert going all the way through. Then I'll do as you did and trim off the excess coils of the insert.

But I do understand your explanation that the insert won't move anyway.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 24 Jun 2017, 17:07

by itchyfeet

Taps don't work like that, the tap when cutting a thread does not just stop it tapers out, so what would happen is the helicoil would not just stop it would be squeezed in and it would all bind up.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Posted: 24 Jun 2017, 17:18

by CJH

Yeah, I know - but I could control the depth easily enough while working on the bench. If it did cause the plug to bind up I could pull the insert out and try a new one slightly less deep. Or just give up and tap the hole all the way through.

I'm done defending an idea that I'm not committed to.