Page 13 of 23

Re: WBX

Posted: 22 Aug 2016, 20:07

by Jawin89

I'm watching this with interest as i think my crankshaft oil seal has started to leak after only 400 miles of use from the rebuild. I set the end play following the engine rebuild and i am 99.9% certain it was correct. Gearbox out this coming weekend to investigate.

Re: WBX

Posted: 22 Aug 2016, 20:25

by itchyfeet

If it helps I'm still using this method, because of my error with the clutch lever I have taken the box off four times using this now, most of the work is done with a hydraulic jack but the ratchet straps help to make it much eadier and safer.

I did accidently drive down the motorway at 70mph with the wooden support bar still in place

https://club8090.co.uk/forum/viewtopic.php?f=37&t=140047

https://club8090.co.uk/forum/viewtopic.php?f=37&t=140047" onclick="window.open(this.href);return false;

I have got rid of the s hooks on the ratchet straps which means you can slide them to any location, joined with D shackes now.

I'd buy a new seal, oring and felt ring, if you have a groove you may be able to relocate the seal as I did but you won't want to put the old ones back. Brickwerks Elring seal much cheaper than VWH.

Re: WBX

Posted: 22 Aug 2016, 20:30

by itchyfeet

ajsimmo wrote:Well my quick thought on a possible repair option seems to have sparked a discussion all of its own! Never done it myself on a flywheel, only a transmission output flange. I was just thinking out loud.

Keep thinking out loud, in fact if you can think of how to trim one out loud without a lathe so we can all fit them that would be great

Re: WBX

Posted: 22 Aug 2016, 20:48

by Jawin89

Thanks for that i will give it a go. Going to order the new bits ready and see how it goes. The seal in there now is an Elring and was part of the full gasket kit. Out of interest, i presume yours was Elring too ?

Re: WBX

Posted: 22 Aug 2016, 20:56

by itchyfeet

Yes Elring before and after, I think it was the seal surface but I wonder if a bent shim retainer could have contributed.

Re: WBX

Posted: 22 Aug 2016, 21:11

by Jawin89

It may well have done, I will see what i find when mine is removed and report back.

Not sure how you would cut the seal sleeve back properly without using a lathe as you would need to be careful not to damage the shim seating face. Most abrasive cutting methods would run the risk of leaving burrs that would have to be removed and there would then be the risk of damaging the sleeve face.

Re: WBX

Posted: 23 Aug 2016, 08:32

by itchyfeet

I'm wondering if you could just use a dremmel cutting disc and trim it before you install it

I will try cutting something thin like a beer can.

Re: WBX

Posted: 23 Aug 2016, 11:40

by tobydog

How much do you need to reduce the length of the sleeve? Would it be possible to use a sheet of wet & dry paper (kept wet) on a flat surface and carefully lap it down to length by hand?

Re: WBX

Posted: 23 Aug 2016, 12:22

by itchyfeet

tobydog wrote:How much do you need to reduce the length of the sleeve? Would it be possible to use a sheet of wet & dry paper (kept wet) on a flat surface and carefully lap it down to length by hand?

no chance I'd have that patience, its about 15mm and needs to be 6-8 mm

length varies because flywheels have slightly different radius or fillet shape

Just ordered one, somebody has to be the guineapig

Re: WBX

Posted: 23 Aug 2016, 19:39

by itchyfeet

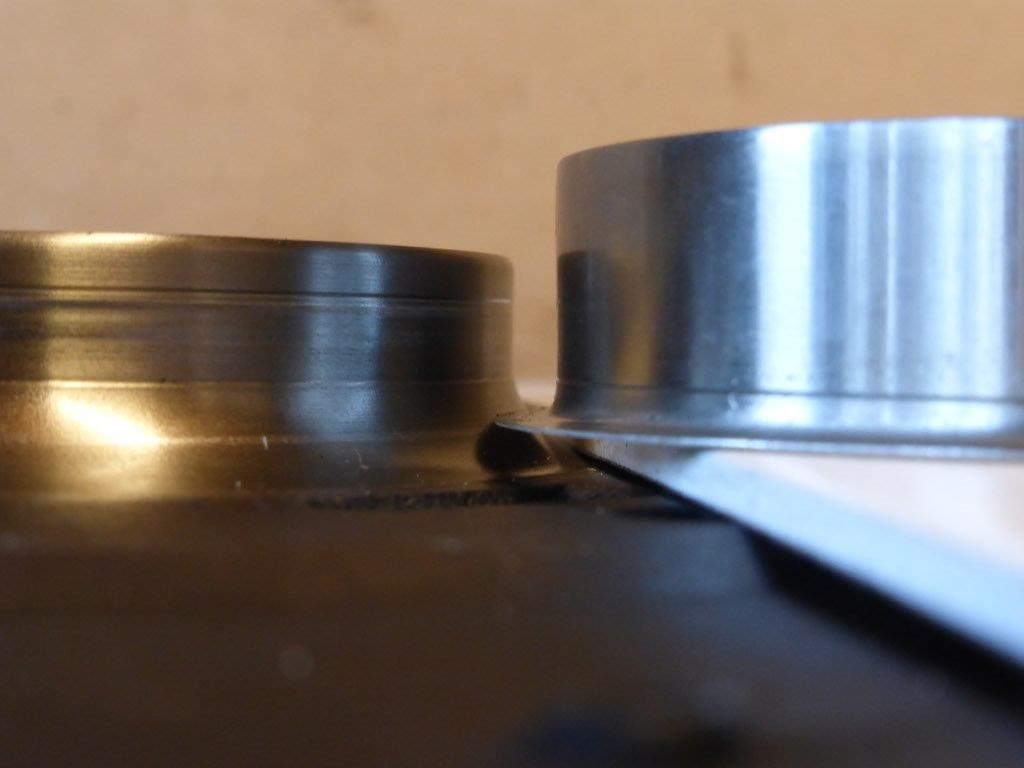

Tried cutting a beer can which is almost the same thickness at 0.15mm and it worked well, yes it leaves a burr but it can be removed with wet and dry.

Depth gauge was crude, I need to rig something better up but I don't think it really matters if the edge isn't perfect as long as it's smooth.

Used best part of a disc doing it so need to order some fresh ones.

I did have to check that the beer can wasn't by coincidence 75mm in diameter, how great would that have been

P1050155

P1050155 by

Paul_Barr, on Flickr

Some exhaust progress also tonight

P1050141

P1050141 by

Paul_Barr, on Flickr

Re: WBX

Posted: 25 Aug 2016, 17:29

by itchyfeet

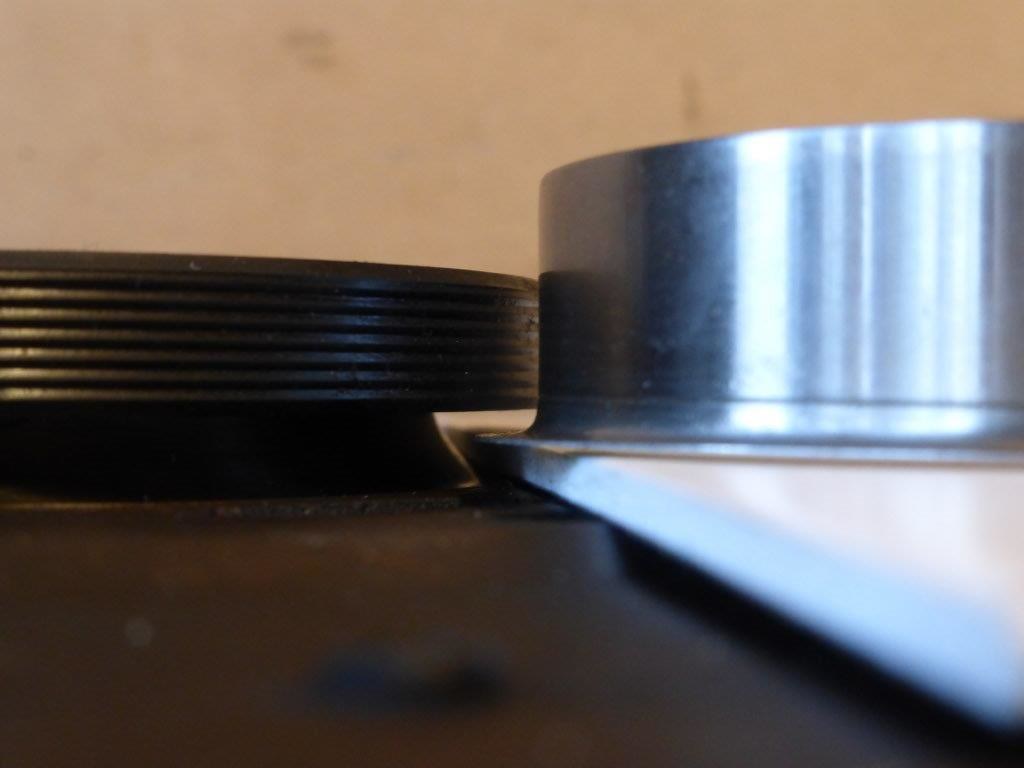

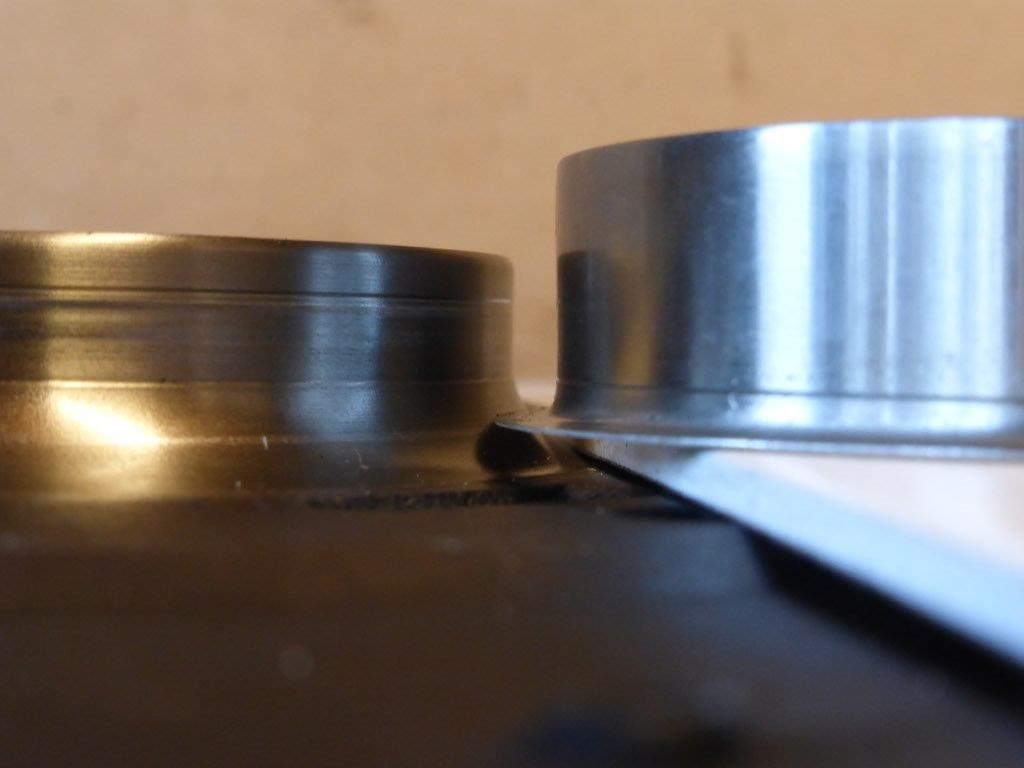

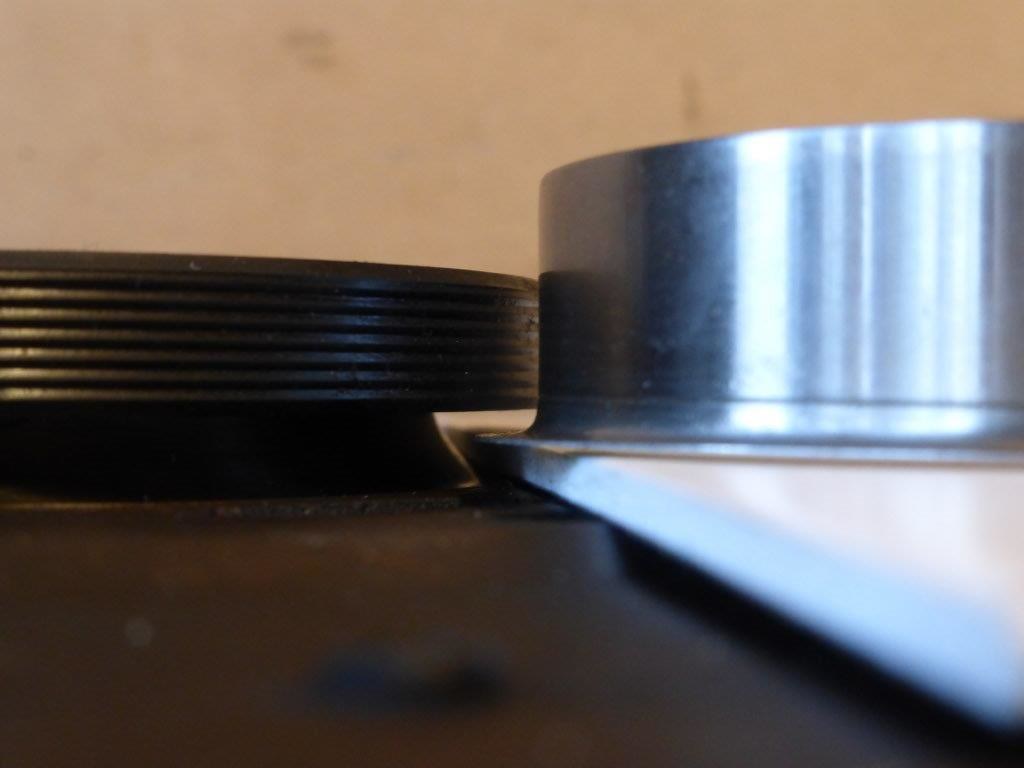

Flywheel off my origional engine that I want to rebuild, it also has a groove but it's close to central so moving the seal to miss it is not really an option, it is also leaking, not badly but you wouldn't want o fit it to a rebuild.

Sleeve won't go on any more than this, about 9mm of flat and then 6 mm of chamfer/fillet.

P1050165

P1050165 by

Paul_Barr, on Flickr

10mm oil seal will push in 3mm under flush in crankcase and the back will sit level with the end of flywheel, this shows that you should be able to leave the rim on if you push the seal home.

P1050167

P1050167 by

Paul_Barr, on Flickr

You would need to cut about 6mm off the sleeve.

P1050168

P1050168 by

Paul_Barr, on Flickr

Re: WBX

Posted: 26 Aug 2016, 19:03

by itchyfeet

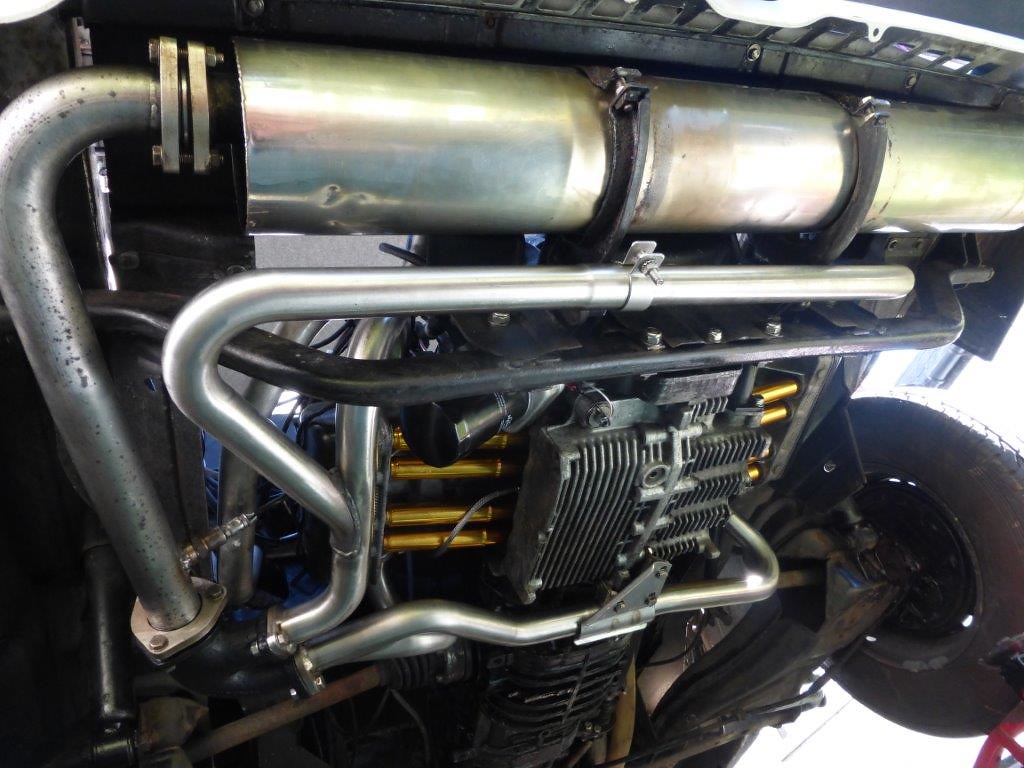

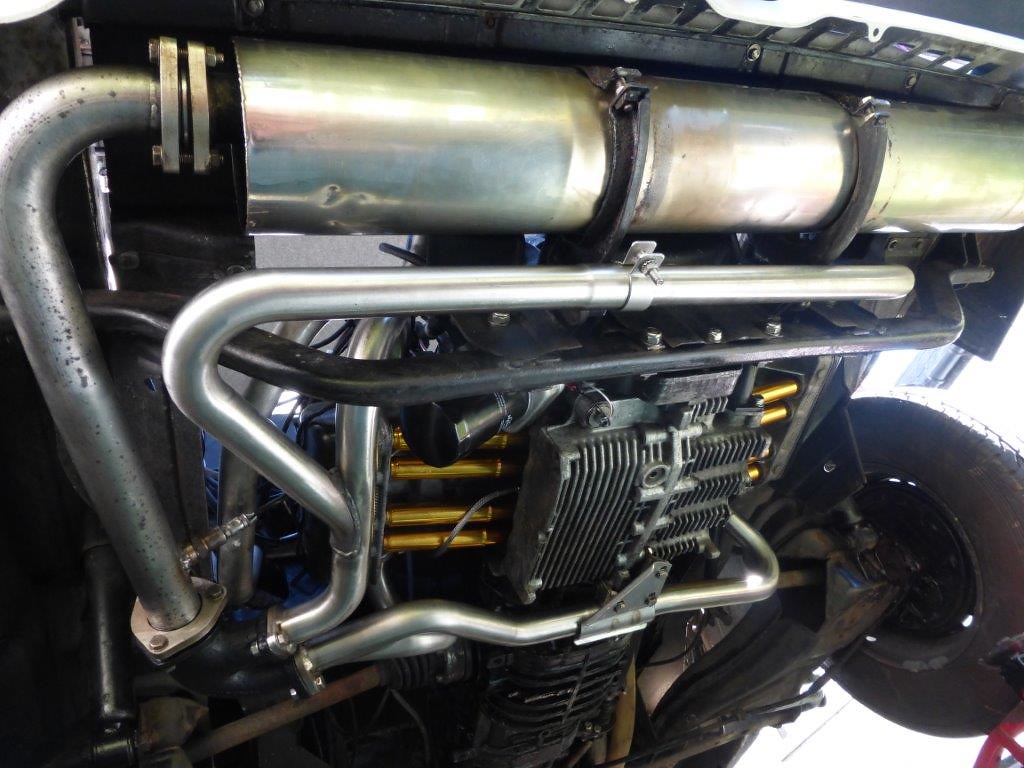

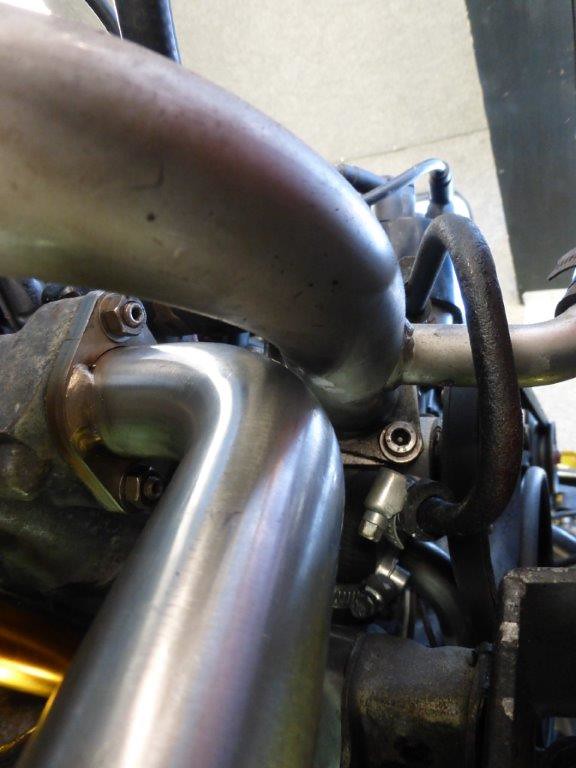

While you were all stuck in traffic this afternoon I was doing this

Second hand stainless Silencer.

Second hand intermediate pipe which has a lambda boss welded in.

Standard cast knuckle which was de rusted by electrolysis and painted with high temp paint.

New Brickwerks 1&3, 2&4 pipes, steel bolts supplied in on 1&3 strap changed to stainless.

Second hand big bore tail pipe.

8xStainless M8x 40mm grub screws, stainless nuts flat washers into heads

6xStainless M8x 40mm bolts and nuts for intermediate pipe with two new olives.

4x Stainless M8x 30mm bolts, washers and nuts for cast knuckle to engine pipes.

3x stainless M8x16 &1xM8x40 stainless bolts, washers and nut for 1&3 pipe clamp bracket

1x M8x 40 stainless bolt, washer and nut for 2&4 pipe clamp bracket.

4x elring exhaust gaskets to heads

2x cheapo gaskets to cast knuckle

Needs stainless saddles and silencer straps to finish it off.

P1050172

P1050172 by

Paul_Barr, on Flickr

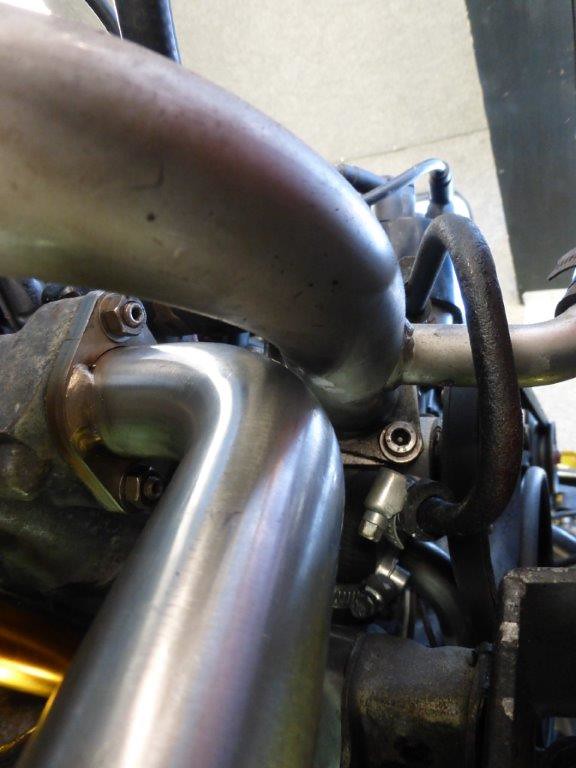

P1050179

P1050179 by

Paul_Barr, on Flickr

a bit close

P1050177

P1050177 by

Paul_Barr, on Flickr

Re: WBX

Posted: 28 Sep 2016, 18:39

by ajsimmo

Nice scat tubes (snigger), but no covers?

Sent from my SM-T210 using Tapatalk

Re: WBX

Posted: 28 Sep 2016, 18:51

by itchyfeet

you are right, the old covers are tired and rusty.

I was going to make some from sheet aluminium, if I don't get around to it I will get these...

My thinking is covers are there to protect delicate push rod tubes, not so important if they are replaceable.

Also scat tubes are rumoured to leak a bit so I want to monotor them, supplied seals are pants buy the small elring seals x16

https://www.brickwerks.co.uk/t3-parts/t ... overs.html" onclick="window.open(this.href);return false;

I still need to fit and test the speedi sleeve, will keep you posted

Re: WBX

Posted: 29 Sep 2016, 06:59

by itchyfeet

On second thoughts if you loose a pushrod tube by a flying stone oil will pour out.

If the oil hits the hot exhaust it could catch fire.

Unlikely but possible so I will fit covers asap.

https://club8090.co.uk/forum/viewtopic.php?f=37&t=155397" onclick="window.open(this.href);return false;