As promised, here's a few pics I took as I went along. It's not an exhaustive photo story, but hopefully it'll help someone

if the Mods think any of them will be useful for the Wiki, please feel free to add them

The first thing to do is get your van's arshe up in the air, crawl underneath her and get the drive shaft off, starting with the gearbox end: -

I used a ratchet and hex key as all mine were hex, but sometimes you'll find that some of the bolts are star-shaped - I have a set of star sockets for the Triumph so if I'd have come across any it wouldn't have been a problem.

Next is the end of the drive shaft inside the bearing housing at the wheel end. This is renowned for being a bit tricky. I used an extension bar on the ratchet, and tied up the free end of the drive shaft with string out of the way so that I could get to all the bolts. They all came off bar one,, which was starting to round off as I tried to get it off. In the end I hammered a 10mm (If I remember correctly) onto it with the extension bar, which was a tight enough fit that when I put the ratchet on it, it started to turn. At this point, I order a set of bolts from the Bay of Fleas to replace some of the dodgier looking ones I'd taken off!!

When you've got the driveshaft off, stick a plastic bag over each end to save any muck or grime getting on the joints, or any of the grease coming off them and all over the family cat or the baby, and pop it somewhere safe for the duration of the job.

Next job is to remove the split pin, and get the castle nut off. It's a 46mm socket - I had to buy one especially, just over £20 from a local tool specialist. Ouch. Once the split pin is out, you'll almost certainly need to put the wheel back on, drop the van back to the ground, and then loosen the castle nut.

With the van back in the air, and the nut off, it's time to remove the drum. It'll be full of brake dust so be as gentle as you can be. Remove the two retaining bolts first, then simply pull the drum off. Mine needed a few persuasive taps around the edge with a hammer to remove it.

Undo the brake line at the rear. I clamped the rubber part of the brake pipe to minimise fluid loss before doing this. You will still need to bleed the system afterwards though.

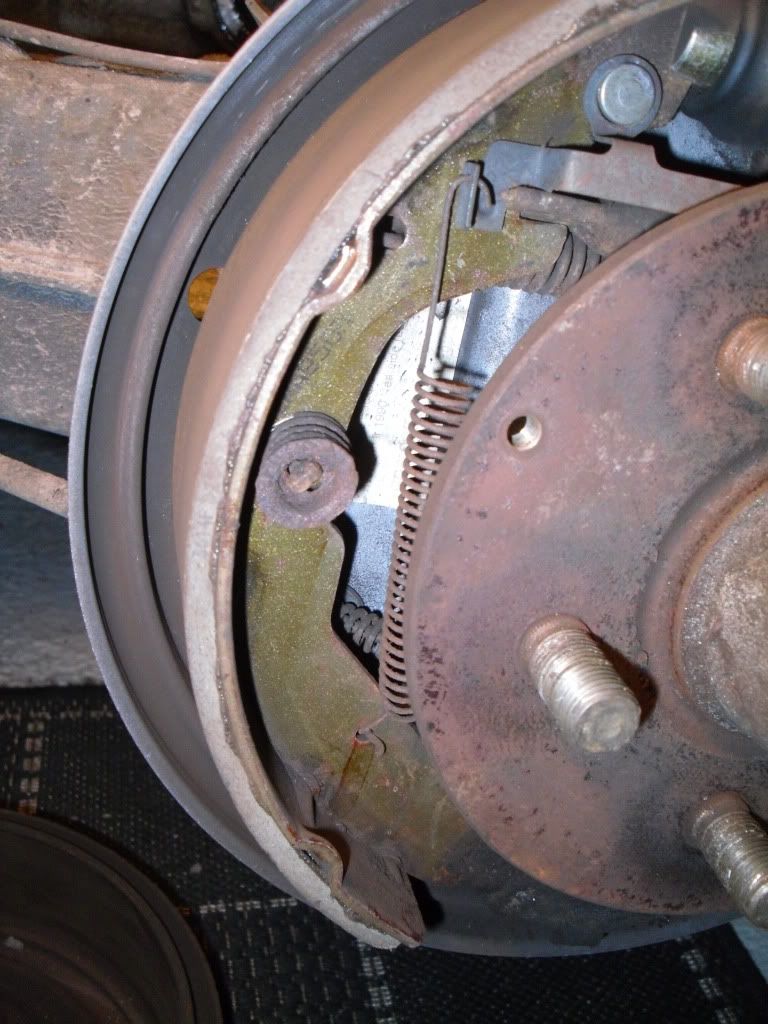

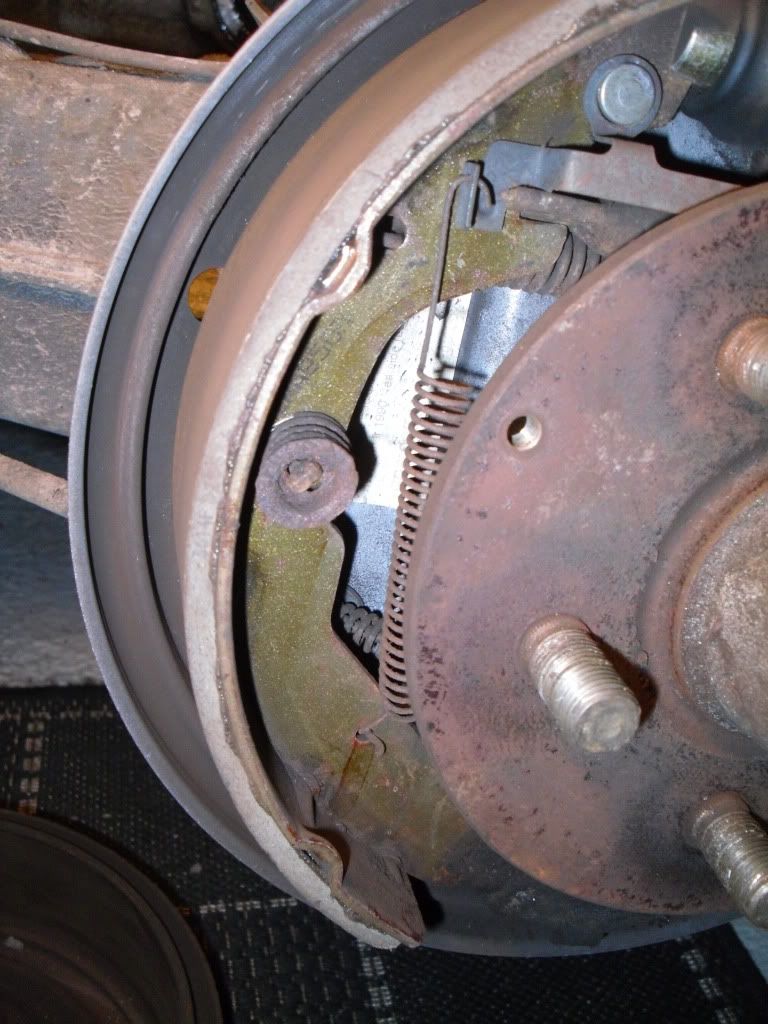

The wheel mounting plate should now pull off, although you may need to offer some "gentle persuasion". Once it's off, you'll have all the gubbins inside the brake drum on view. I'd advise taking a photo or two at this point if you're not familiar with how everything goes together, so that you can put it all back together again properly when you've finished

This is mine, but after I'd started taking springs and retaining clips out. Photograph yours before you start.

Once everything is out, you can remove the backplate, and then undo the four bolts that hold the wheelbearing housing in place. If you have a hairy-arshed biker with a breaker bar hanging about the place, you'll find him very useful for undoing these bolts, which will likely have not been disturbed for years, and will have been done up very tightly originally

Once the bearing housing is off, I recommend following the instructions in the Haynes manual. I did, they're very clear and accurate, and so long as you follow them exactly, you wont go wrong. I wont reproduce the process here, but a couple of photos may help

Lifting out the oil seal at the inner end of the bearing: -

And the circlip underneath it: -

Drive out the old bearings with a drift, available for no more than a couple of quid at your local tool specialist. Don't use a screwdriver or anything else big and hard!! An undersized bearing placer would also work. I used a combination of the drift and a small placer.

When putting in the new bearing parts, follow the Haynes, and pack *everything* in as much grease as you can. I already had some wheel bearing grease for the collection of motorcycles I have, but Halfords do pots of temperature-tolerant grease especially for wheelbearings for just a few quid. The bearings I bought from Brickwerks had a sachet of grease supplied, but I'd buy a pot anyway. You just know that sachet will end up in the (a) dog, (b) mug of tea, or (c) the baby.

Driving in the outer bearing with a bearing placer: -

Popping in the outer seal. As you can see, I used a block of wood rather than a placer for this, and tapped GENTLY and squarely to ensure it went in evenly: -

The finished job, before putting everything back on the van: -

Putting everything back together is simply a reverse of taking it all off. Follow the instructions in the Haynes for adjusting the rear brake shoes once you've got the brake assembly back together. Doing it properly the first time will save a lot of frustration later, I promise you. Putting the drive shaft back on can sometimes be a nightmare, although mine went back very easily. Do the wheel end first, and them have a friend rotate the hub to match up the holes at the gearbox end of the shaft. Again, I tied up the driveshaft with some string to make this job a lot easier. When you are ready to put the castlenut back on, use a length of scaffolding pole over your torque wrench to get the necessary leverage, as per this photograph. Please note though, that this photo is for effect only - your wheel must be on and ON THE GROUND before tightening up.

Once completed, award yourself a night on the lash at a beer festival with friends