Page 2 of 8

Re: 300CE WBX Repair

Posted: 08 Apr 2018, 18:28

by itchyfeet

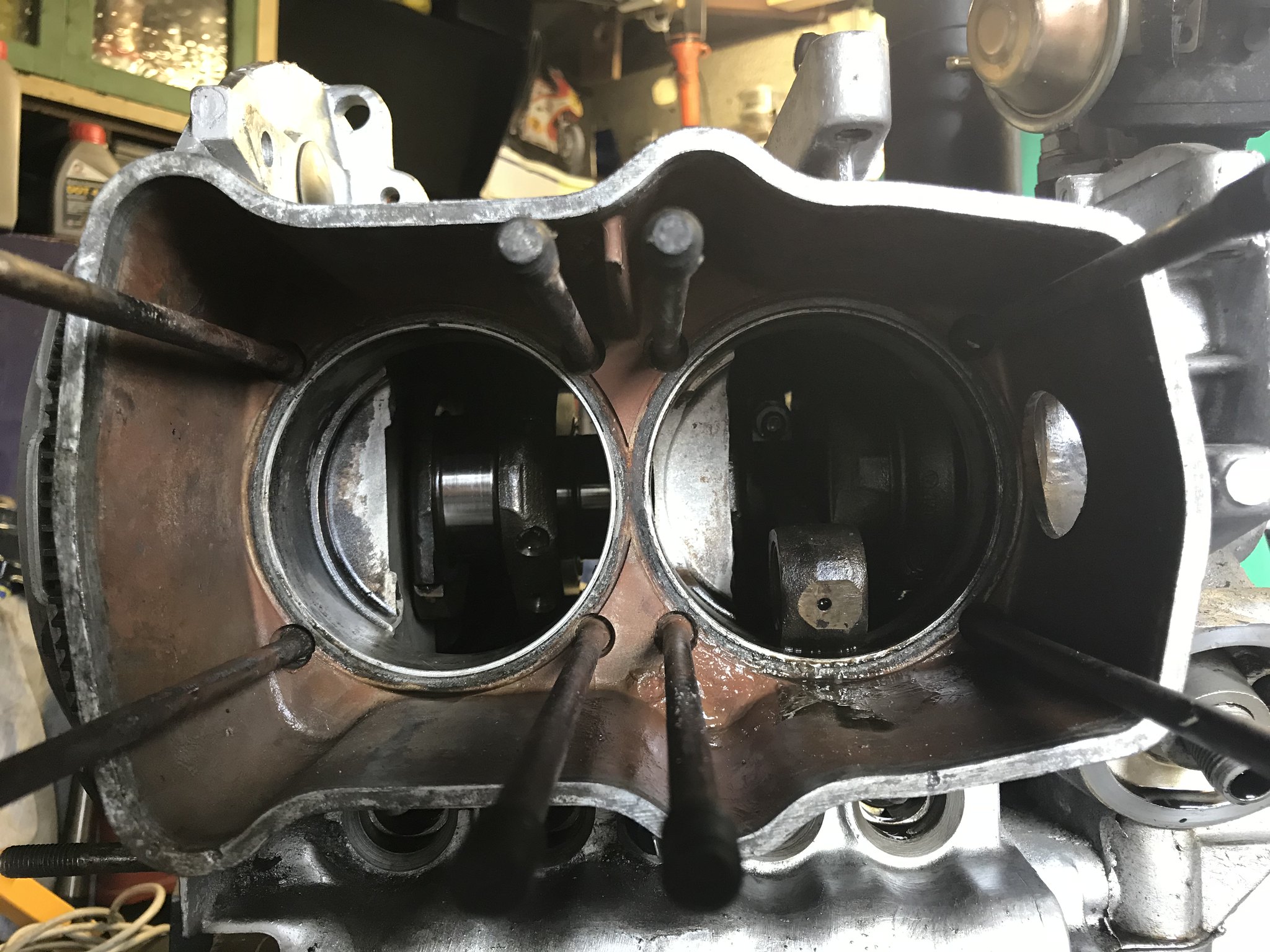

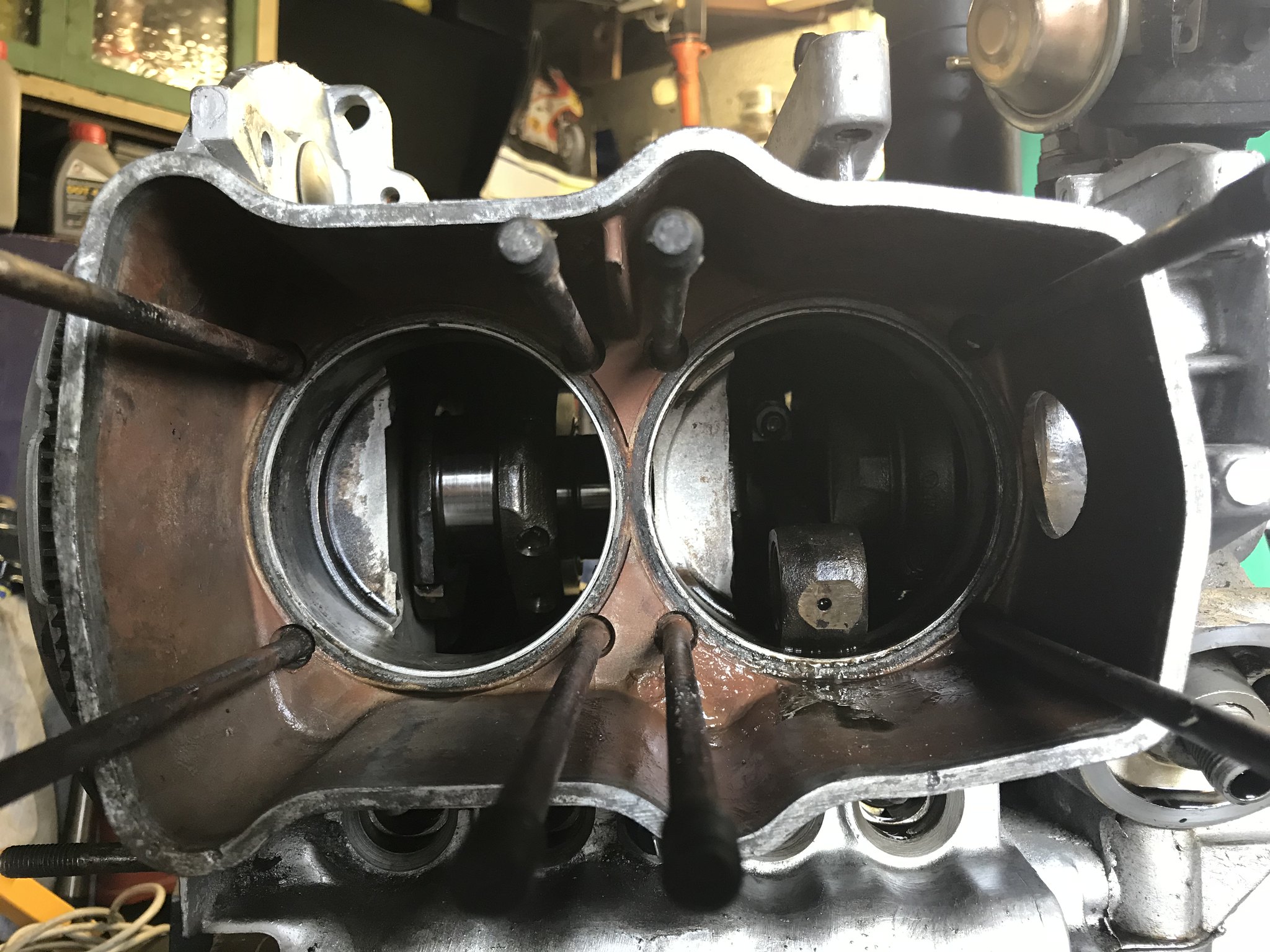

try fine grinding paste and brake fluid with an old barrel, need to do both chambers of the head the same number of turns and keep it dead square, i.e. apply pressure evenly while rotating

P1060157

P1060157 by

Paul_Barr, on Flickr

Re: 300CE WBX Repair

Posted: 08 Apr 2018, 18:47

by 300CE

itchyfeet wrote:try fine grinding paste and brake fluid with an old barrel, need to do both chambers of the head the same number of turns and keep it dead square, i.e. apply pressure evenly while rotating

P1060157

P1060157 by

Paul_Barr, on Flickr

Cheers Paul for the advice and info, it’s much appreciated as always - this looks like the next course of action. Will try this method on the existing head with the new fire rings, barrels and seals to see if this resolves the problem. I know it could mean more work, but we’ll be prepared to remove and change the head with the spare I bought should the problem reoccur.

Re: 300CE WBX Repair

Posted: 09 Apr 2018, 13:06

by 300CE

Quick question - would it be worth using the above method with the new barrel so it wears in the same?

Re: 300CE WBX Repair

Posted: 09 Apr 2018, 14:11

by itchyfeet

300CE wrote:Quick question - would it be worth using the above method with the new barrel so it wears in the same?

personally I'd just use an old barrel no point ruining the finish on the new barrel

Re: 300CE WBX Repair

Posted: 09 Apr 2018, 18:14

by 300CE

itchyfeet wrote:300CE wrote:Quick question - would it be worth using the above method with the new barrel so it wears in the same?

personally I'd just use an old barrel no point ruining the finish on the new barrel

Looks like I was lucky enough to get the last batch of barrels from Heritage. Up to a 12 week waiting list for the next lot.

Re: 300CE WBX Repair

Posted: 09 Apr 2018, 19:27

by itchyfeet

https://www.customandcommercial.com/vw- ... f_4_24013/" onclick="window.open(this.href);return false;

https://www.customandcommercial.com/vw- ... -92_25039/" onclick="window.open(this.href);return false;

doesn't say who makes them

Re: 300CE WBX Repair

Posted: 11 Apr 2018, 19:52

by 300CE

Cheers - New barrels arrived today from Heritage:

Untitled

Untitled by

Justin C, on Flickr

Re: 300CE WBX Repair

Posted: 11 Apr 2018, 20:24

by itchyfeet

ohhhhhh

Re: 300CE WBX Repair

Posted: 11 Apr 2018, 22:16

by 300CE

Shiny, shiny! Should be back on it this weekend Paul using your advice above on the head. Also got a pal coming round on Sunday to weld up a hole located in the engine bay. Also gives me a week to then build up some brownie points with the missus as I’ve been ‘working on that bloody van’ all weekend.

Re: 300CE WBX Repair

Posted: 13 Apr 2018, 16:57

by 300CE

Quick question chaps - is there a specific way/knack of getting the pistons back into the barrels when the casing hasn't been split?

Any advice much appreciated.

Re: 300CE WBX Repair

Posted: 13 Apr 2018, 17:04

by george2490

Which sort of ring compressor are you using?

I wrestled mine in with jubilee clips then bought a proper compressor with ratchet. Much easier.

Patience is vital!

Ruined an oil ring first time.

Sent from my SM-A320FL using Tapatalk

Re: 300CE WBX Repair

Posted: 13 Apr 2018, 17:35

by itchyfeet

I put the pistons in the barrels before fitting to engine.

https://club8090.co.uk/forum/viewtopic.p ... 0#p8207502" onclick="window.open(this.href);return false;

https://club8090.co.uk/forum/viewtopic.p ... 5#p8207909" onclick="window.open(this.href);return false;

Re: 300CE WBX Repair

Posted: 13 Apr 2018, 18:01

by 300CE

Many Thanks for the replies chaps! Not sure on ring compressor but my mate has some in his garage.

Paul, my pal said those links helped massively and that it’s made total sense on how to get the job done

Re: 300CE WBX Repair

Posted: 15 Apr 2018, 08:48

by 300CE

OK, pistons removed ready for cleaning. Took of the water pump to enable to pin to be taken out on one side:

Untitled

Untitled by

Justin C, on Flickr

Undid the conrod to enable removal of the left hand piston:

Untitled

Untitled by

Justin C, on Flickr

Job completed on the opposite side:

Untitled

Untitled by

Justin C, on Flickr

Shells looked good as did the cleanliness of the internals (I drop the oil out religiously every 6 months):

Untitled

Untitled by

Justin C, on Flickr

As there won't be any oil in this area upon the first start up, graphite paste put on the shells before re-installment to minimise wear - non stretch bolts mean these can be reused and re-torqued to 45nm (thanks Paul!!) :

Untitled

Untitled by

Justin C, on Flickr

Piston's boxed and marked up ready for cleaning:

Untitled

Untitled by

Justin C, on Flickr

Internals covered ready for wire brushing the studs. Luckily all studs were in a good condition:

Untitled

Untitled by

Justin C, on Flickr

As the engine's out, it makes sense to replace the oil pump so that'll be another purchase this week. Next weekend will be lots more cleaning and reinstallment of the barrels, pistons and piston rings. I'm probably going to paint up the block as well and a new stainless exhaust will be on the cards!

Re: 300CE WBX Repair

Posted: 15 Apr 2018, 10:58

by itchyfeet

oil gallery drilling plug looks in good condition, you can see it between the lower center studs, always worth checking it.

you don't need to remove conrods.

Untitled

Untitled by

Justin C, on Flickr

Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr Untitled by Justin C, on Flickr

Untitled by Justin C, on Flickr