Page 2 of 2

Re: Am I Being Naive?

Posted: 14 Nov 2017, 18:18

by Snowmark

Just an update - exhaust is off! 6 of the studs came clean out with the rusted on nuts, two left in as the nuts came free, think I'll probably leave these as I don't want to push my luck.

VW Speedshop Stainless exhaust to order - any fitting tips/gaskets/nuts etc???

Thanks

Re: Am I Being Naive?

Posted: 14 Nov 2017, 18:27

by DoubleOSeven

Tip No.1, put the nuts onto the exhaust studs before assembly, just a few turns so they are flush. Then put the studs into the heads. That way the nuts will tighten up long before the studs bottom out, which you ‘don’t’ want. Hope that makes sense.

Sent from my iPhone using Tapatalk

Re: Am I Being Naive?

Posted: 14 Nov 2017, 18:41

by Snowmark

I think so - basically, I want the nut to tighten against the exhaust flange before the stud touches and tightens against the casing.......

Makes sense and also, hadn't even considered that - thanks!

Re: Am I Being Naive?

Posted: 14 Nov 2017, 18:50

by itchyfeet

If you buy stanless grubscrews they have an internal hex to adjust depth and they don't rust.

Balls to anybody who mentions bimetalic corrosion, been using them for 10 years.

Re: Am I Being Naive?

Posted: 14 Nov 2017, 20:04

by itchyfeet

Re: Am I Being Naive?

Posted: 14 Nov 2017, 20:09

by Snowmark

Yep, got SS studs. Spring washer and SS nuts?

Re: Am I Being Naive?

Posted: 15 Nov 2017, 07:45

by itchyfeet

I just use flat washers but no harm in spring ones I can think of.

Re: Am I Being Naive?

Posted: 15 Nov 2017, 09:58

by ajsimmo

Be careful with SS nuts on SS studs, as thread galling could make them impossible to remove undamaged in future. I'd use anti-seize (copper coated) nuts instead, with SS flat washers.

Re: Am I Being Naive?

Posted: 15 Nov 2017, 10:12

by Ian Hulley

That ^ meant I had to take my engine out

it's the stud below the thermostat housing and underneath the bend of the exhaust

Fortunately I've done a fair few over the years

I agree ... freeze-it spray, plus gas, cobalt drills, easy-outs (left handed tapered drills) good quality Vice-grips and precision pointed blow lamp are all essential tools for the aged exhaust removal. I used normal M8 BZP studs and copper-coated M8 exhaust nuts to fit the new system. I removed all the old studs and cleaned out all the threads and copper-slipped them all prior to re-assembly. I also used double nuts where the push rod tube shields are mounted so the exhaust doesn't have to be loosened off should the (stainless) shields ever need to come off.

Ian

Re: Am I Being Naive?

Posted: 15 Nov 2017, 11:12

by itchyfeet

ajsimmo wrote:Be careful with SS nuts on SS studs, as thread galling could make them impossible to remove undamaged in future. I'd use anti-seize (copper coated) nuts instead, with SS flat washers.

Cheap stainless nuts and studs can have badly formed threads but im my experience its very rare unless you over tighten.

check the nut runs freely on the stud, any grittyness is a badly formed thread.

my whole exhaust is all staless bolts and studs and nuts about 30 in total, been on and off maybe 5 times in 10 years and not galled one

Re: Am I Being Naive?

Posted: 29 Nov 2017, 22:44

by Snowmark

OK, so I'm a complete idiot......

6 out of 8 studs came clean out without a fuss. The other 2 were fine and would have cleaned up to be reused.

For some unknown reason I decided just to try and remove one of the old studs and obviously snapped it......

Today was spent drilling it out. To be honest it went OK (I think). I now have a hole drilled out to 6.5mm and a depth of 19mm. However, the threads have not collapsed as I expected and they seem to be welded to the casing.

I guess my next move is to tap the hole I've made - any help gratefully received.

What tap to buy (currently just have a cheap Aldi set)

Any tips for getting it started? I guess I have to be dead straight.

If I make a proper Horlicks of it is there an escape - could i drill out larger and helicoil or use a M!0 stud that reduces to a M8?

Thanks for any advice - feeling a little stressed.

Re: Am I Being Naive?

Posted: 30 Nov 2017, 07:54

by itchyfeet

if you cant remove all the old steel stud you really have to drill out and helicoil M8 helicoil needs a larger hole so should be fine, I have all the helicoils drills and taps if you want to borrow them or they are not so expensive to buy, just like the drill you need to start the tap straight long bolt in the othef hole and align by eye.

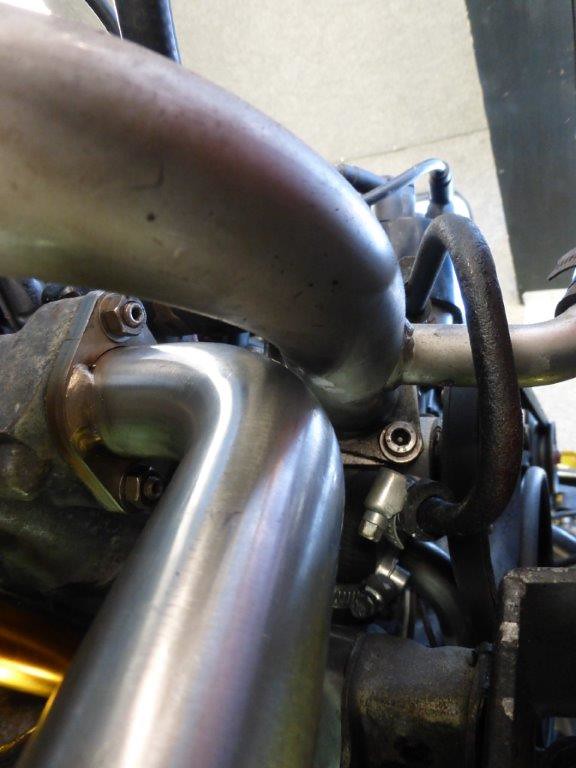

P1060051

P1060051 by

Paul_Barr, on Flickr

P1060052

P1060052 by

Paul_Barr, on Flickr

Re: Am I Being Naive?

Posted: 30 Nov 2017, 21:52

by Snowmark

Thanks Itchy,

I’ve PM’d you

Re: Am I Being Naive?

Posted: 30 Nov 2017, 22:08

by waltraud

Snowmark wrote:Thanks Itchy,

I’ve PM’d you

Good work !!

Sent from my iPhone using Tapatalk