Page 9 of 23

Re: WBX

Posted: 05 Jun 2016, 07:33

by itchyfeet

Got down to 1 bar at 2000 rpm on my tired old wbx after a long steep hill on a motorway yesterday

buzzer kicks in at 0.9 bar so it must be ok

Re: WBX

Posted: 20 Jun 2016, 07:47

by itchyfeet

I purchased a DG cam from VWH, seems a bargain at 75 quid.

It is part number 025109021C which is a zero size gear, interesting that it's not stamped with a number, I guess they didn't bother stamping a zero.

Re: WBX

Posted: 20 Jun 2016, 18:03

by ajsimmo

itchyfeet wrote:I purchased a DG cam from VWH, seems a bargain at 75 quid.

You weren't tempted by their identical item on eBay, then? See

http://tinyurl.com/HFM?SIUYA!

Re: WBX

Posted: 20 Jun 2016, 18:07

by silverbullet

Are those the Aircooled regrinds? 240 notes...

Ich fahre einen Bulli. Ich hilfe mir selbst...meistens!

Re: WBX

Posted: 20 Jun 2016, 18:21

by itchyfeet

ajsimmo wrote:itchyfeet wrote:I purchased a DG cam from VWH, seems a bargain at 75 quid.

You weren't tempted by their identical item on eBay, then? See

http://tinyurl.com/HFM?SIUYA!

3 sold

one born every minuite

No the regrinds are for DJs how they can say genuine VW and list a DJ cam number when it's a regrind I don't know

https://www.vwheritage.com/shop/type25- ... StartRow=1" onclick="window.open(this.href);return false;

Re: WBX

Posted: 22 Jun 2016, 18:04

by itchyfeet

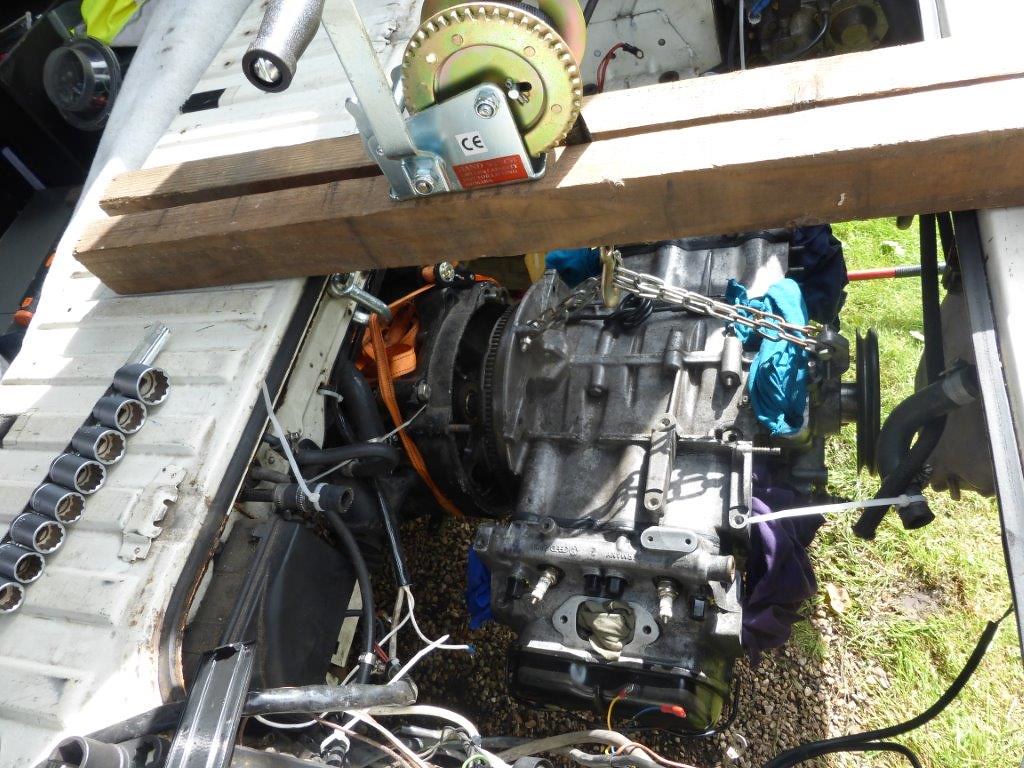

Engine now stripped of components ready to pull out.

A lot of people drop the engine almost complete but this is easiest done with gearbox, when just engine is coming out then some stuff has to come off because it has to slide off the input shaft.

I have no garage or dry storage for an engine with all the bits on so I strip it in the van and then remove it, it works for me.

All these bits have to come off anyway to refit to the replacement bare engine.

P1040766

P1040766 by

Paul_Barr, on Flickr

P1040768

P1040768 by

Paul_Barr, on Flickr

WBX

Posted: 24 Jun 2016, 19:22

by itchyfeet

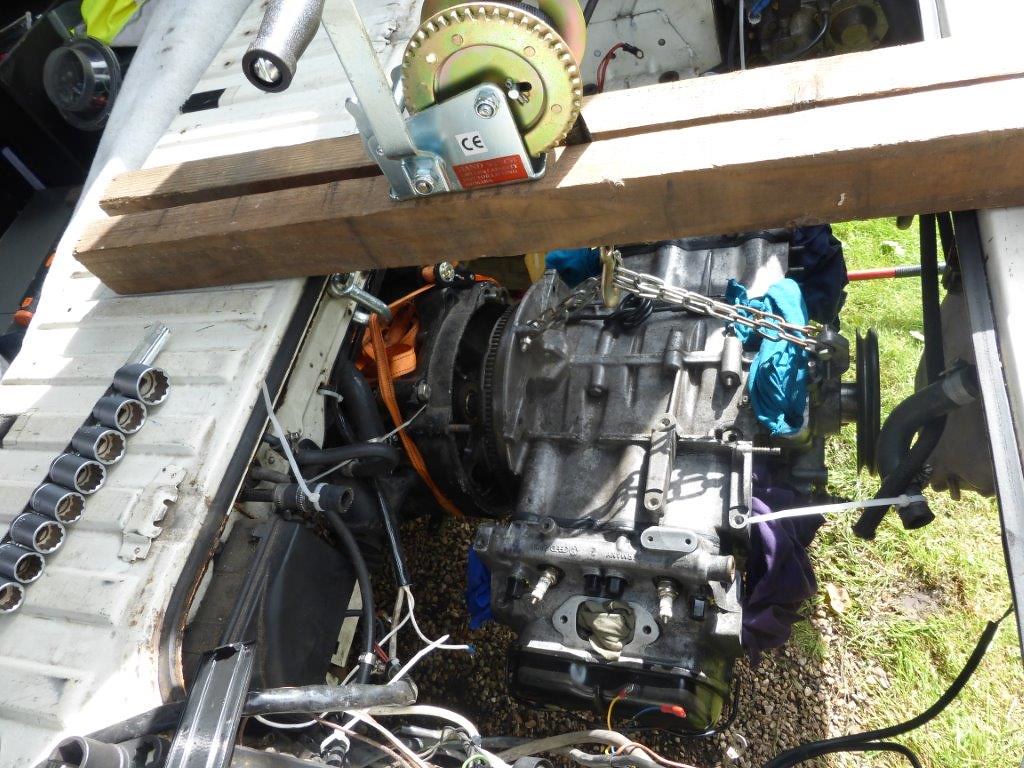

Today I tried a fresh approach to DIY removal of a WBX

I have previously used the ratchet strap and fence post method but it's a bit crude, I have been criticised for stressing the manifold ( I doubt it) and ratchet straps are not good releasing, they tend to just give way.

This is a 15 quid strap winch from Ebay, two 3x2 inch wooden supports and 2x M8x 80mm bolts. The winch is designed to lift not drop but it has a 4:1 ratio and with a decent length handle it's easy to wind a WBX down ( can't weight more than 100Kg I can just lift it)

Gearbox strapped to the bulkhead with a large D shackle and a ratchet strap, two pieces of chain with M8 bolts through the lifting points.

Release the engine to gearbox bolts and remove the engine bar, then slide the winch with engine back off gearbox and lower.

After the engine is dropped the van can be lifted by jacks to slide the engine out and the gearbox remains in the right position relative to the van ready for the new engine to go in.

P1040783

P1040783 by

Paul_Barr, on Flickr

P1040785

P1040785 by

Paul_Barr, on Flickr

P1040786

P1040786 by

Paul_Barr, on Flickr

New engine easy to align with gearbox

P1040791

P1040791 by

Paul_Barr, on Flickr

P1040792

P1040792 by

Paul_Barr, on Flickr

P1040793

P1040793 by

Paul_Barr, on Flickr

Re: WBX

Posted: 24 Jun 2016, 21:28

by Jawin89

Looking good. Great idea with the piece of cloth pushed into the open holes. Stops anything falling in during reassembly. Ask me how I know

Telescopic rods with magnets on the end are a god send !!

Re: WBX

Posted: 25 Jun 2016, 10:17

by itchyfeet

Jawin89 wrote:

Telescopic rods with magnets on the end are a god send !!

I use alot of stainless fixings, a magnet isn't much use with them.

Pea shingle on my drive isn't magnetic either

Re: WBX

Posted: 25 Jun 2016, 18:27

by itchyfeet

After a hard days spannering it's in and running.

I didn't bother stripping an filling tappets with oil so I could not preload them because they were spongy, I just set an approx. adjustment and fired it up.

Noisy at first but quietened down once hot, I had 2bar at hot idle so it's looking like a good engine but early days

Need to set preload tomorrow

P1040808

P1040808 by

Paul_Barr, on Flickr

P1040798

P1040798 by

Paul_Barr, on Flickr

Rebuild coming.....

Hard to think this engine just did 800 faultless miles to france arriving home last Saturday.

P1040809

P1040809 by

Paul_Barr, on Flickr

Re: WBX

Posted: 26 Jun 2016, 18:15

by itchyfeet

Test drive today, drove it like I stole it, looking good

Re: WBX

Posted: 27 Jun 2016, 06:55

by itchyfeet

Is the laser 2070 honing tool good for honing barrels?

Do I need to keep the drill dead square or does the spring loaded pivot system take out any slight angle of the drill?

http://www.ebay.co.uk/itm/LASER-TOOLS-2 ... SwdvpWEmDx" onclick="window.open(this.href);return false;

Re: WBX

Posted: 27 Jun 2016, 22:15

by 300CE

What's that leaking in the 2nd pic above Paul? Only joking mate, looking good!

Re: WBX

Posted: 29 Jun 2016, 16:42

by itchyfeet

Cheers Justin, I did have a leak on the oil cooler pipe, there is one hose I forget to tighten every time

I was given a DG engine case and a bucket of bits from it by DoubleOSeven. In it was four barrels but they got a bit of surface rust as it was left outside for a couple of days, probably too much to go straight in with the honing tool so I thought I'd try a bit of electrolysis (also suggested by 007)

This is 3 table spoons of wilko bicorbonate of soda in a washing bowl, strip of stainless, crock clips and a 150W 12V PSU that was gathering dust in a draw.

Mains power meter is showing 80W draw max, after a couple of hours the first one was fairly rust free, just some black oxide which I think will hone off.

Worth a try may not work but good practice for the honing tool if nothing else.

P1040826

P1040826 by

Paul_Barr, on Flickr

Re: WBX

Posted: 30 Jun 2016, 16:50

by itchyfeet

Treated myself to some new tools that arrived today

laser 2070 honing tool looks like the spring loaded pivot system takes out any slight angle of the drill so no need to keep it dead square, seems to work well, says to use brake fluid, this barrel is scrap but good to practice. ( Tip of Laser brand came from SilverB) Used a battery drill on slow and moved it up and down.

P1040832

P1040832 by

Paul_Barr, on Flickr

P1040842

P1040842 by

Paul_Barr, on Flickr

Also got a pair of Knipex 45 21 200 circlip pliers for the crank and would also work well I think on driveshafts, (Tip of which one works came from Mojoh)

They have a small dimple to grip the circlip.

100mm micrometer next

P1040836

P1040836 by

Paul_Barr, on Flickr

P1040766 by Paul_Barr, on Flickr

P1040766 by Paul_Barr, on Flickr P1040768 by Paul_Barr, on Flickr

P1040768 by Paul_Barr, on Flickr P1040783 by Paul_Barr, on Flickr

P1040783 by Paul_Barr, on Flickr P1040785 by Paul_Barr, on Flickr

P1040785 by Paul_Barr, on Flickr P1040786 by Paul_Barr, on Flickr

P1040786 by Paul_Barr, on Flickr P1040791 by Paul_Barr, on Flickr

P1040791 by Paul_Barr, on Flickr P1040792 by Paul_Barr, on Flickr

P1040792 by Paul_Barr, on Flickr P1040793 by Paul_Barr, on Flickr

P1040793 by Paul_Barr, on Flickr P1040808 by Paul_Barr, on Flickr

P1040808 by Paul_Barr, on Flickr P1040798 by Paul_Barr, on Flickr

P1040798 by Paul_Barr, on Flickr P1040809 by Paul_Barr, on Flickr

P1040809 by Paul_Barr, on Flickr P1040826 by Paul_Barr, on Flickr

P1040826 by Paul_Barr, on Flickr P1040832 by Paul_Barr, on Flickr

P1040832 by Paul_Barr, on Flickr P1040842 by Paul_Barr, on Flickr

P1040842 by Paul_Barr, on Flickr P1040836 by Paul_Barr, on Flickr

P1040836 by Paul_Barr, on Flickr