Page 8 of 30

Re: WBXlog

Posted: 09 Nov 2016, 18:52

by itchyfeet

Pistons into barrels and into engine tonight

Made sure everything was in the right direction, oiled barrel piston and ring compressor, then fitted compressor to piston taking care not to move rings when tightening, ring compressor needs to be covering as much of the piston as possible so that when you push it in the piston gets some speed up before passing into the barrel.

P1060288

P1060288 by

Paul_Barr, on Flickr

P1060291

P1060291 by

Paul_Barr, on Flickr

align it and a big shove.

P1060292

P1060292 by

Paul_Barr, on Flickr

P1060293

P1060293 by

Paul_Barr, on Flickr

all four done

P1060294

P1060294 by

Paul_Barr, on Flickr

next I got the engine on the flywheel, the best orientation to make fitting gudgeon pins so con rods don't move under their own weight.

P1060295

P1060295 by

Paul_Barr, on Flickr

Cleaned barrel seal grooves and crankcase mating surfaces with meths, last chance to remove any dirt.

P1060296

P1060296 by

Paul_Barr, on Flickr

P1060298

P1060298 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 09 Nov 2016, 19:04

by itchyfeet

Lower liner seals from gasket set and fit to the barrels

P1060300

P1060300 by

Paul_Barr, on Flickr

Carefully push piston out until gudgeon hole is clear, push too far and rings will come out!!

Check circlip moves both ways by pushing on just one hole (different circlip hole in each direction), if it does it will be in the groove, last chance to make sure, check them all before fitting.

P1060302

P1060302 by

Paul_Barr, on Flickr

align with conrod as best you can then pin in

P1060304

P1060304 by

Paul_Barr, on Flickr

carefully placed rag then circlip in, again check movement on both directions.

P1060306

P1060306 by

Paul_Barr, on Flickr

Push barrel home and align next barrel

P1060307

P1060307 by

Paul_Barr, on Flickr

pin in, rag in, then circlip in.

P1060311

P1060311 by

Paul_Barr, on Flickr

Push barrel home, I fit a wooden clamp with some bits of copper tube to hole them in place, it helps to stop them moving when you turn the engine over to fit the other two barrels.

P1060313

P1060313 by

Paul_Barr, on Flickr

Then when all four barrels in and clamps on both sides the engine can be turned over to check it's all smooth.

P1060314

P1060314 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 09 Nov 2016, 19:22

by 300CE

Almost there Paul, bet you can't wait to get it up and running

Re: WBXlog

Posted: 09 Nov 2016, 19:41

by itchyfeet

Needs to be in by the end of the year so it's well run in and trusted by Summer for the trip to France

Re: WBXlog

Posted: 09 Nov 2016, 21:55

by 300CE

I'm sure it'll be fine chap - you'll have to do a vid of it running!

Re: WBXlog

Posted: 10 Nov 2016, 17:51

by itchyfeet

Time to move on to heads

These are 1998 Polish cast heads ( all the others I have seen are German cast), perhaps some of the latest heads made?

They came fitted to a 2002 VW recon which is now in the van with different heads, they are in great condition, no cracks between valves and no major corosion

P1060316

P1060316 by

Paul_Barr, on Flickr

P1060317

P1060317 by

Paul_Barr, on Flickr

head 3&4 has some oily deposits on No 3, I'm pretty confident this is from a worn barrel/rings due to a cracked head 3 years ago which let water in to this barrel, the barrel is now gone swapped for a better one.

P1060315

P1060315 by

Paul_Barr, on Flickr

head 1 & 2 is good no oily deposits

P1060322

P1060322 by

Paul_Barr, on Flickr

pop the valves out

P1060318

P1060318 by

Paul_Barr, on Flickr

Valve seats are still good, three years since they were last ground.

P1060321

P1060321 by

Paul_Barr, on Flickr

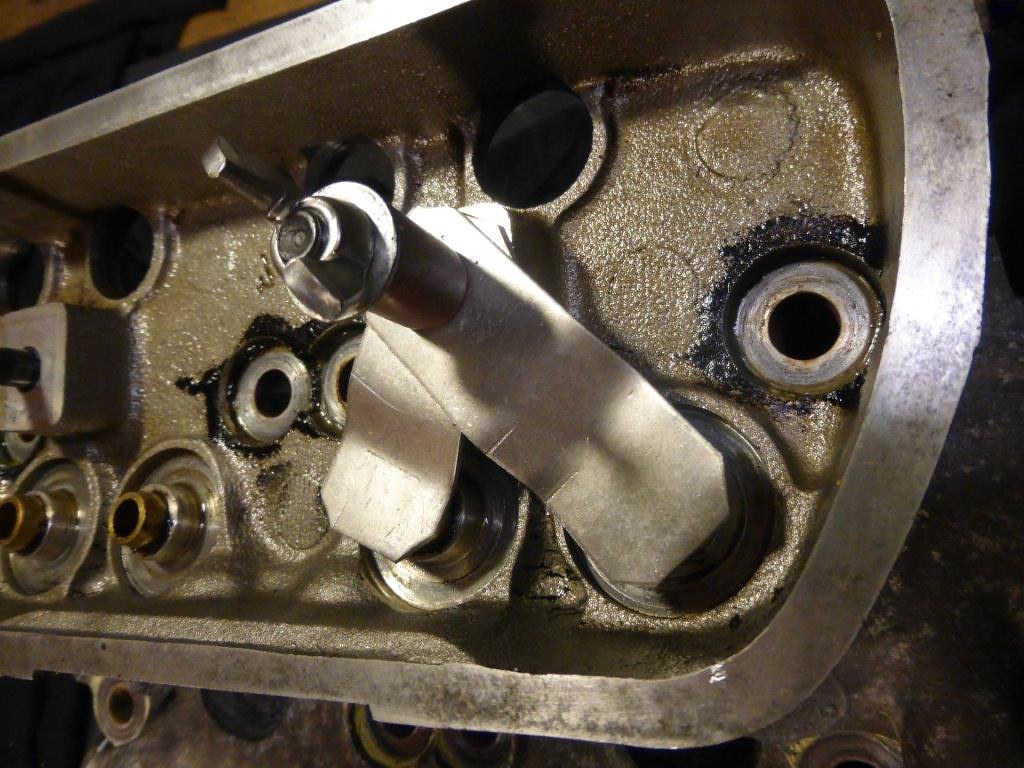

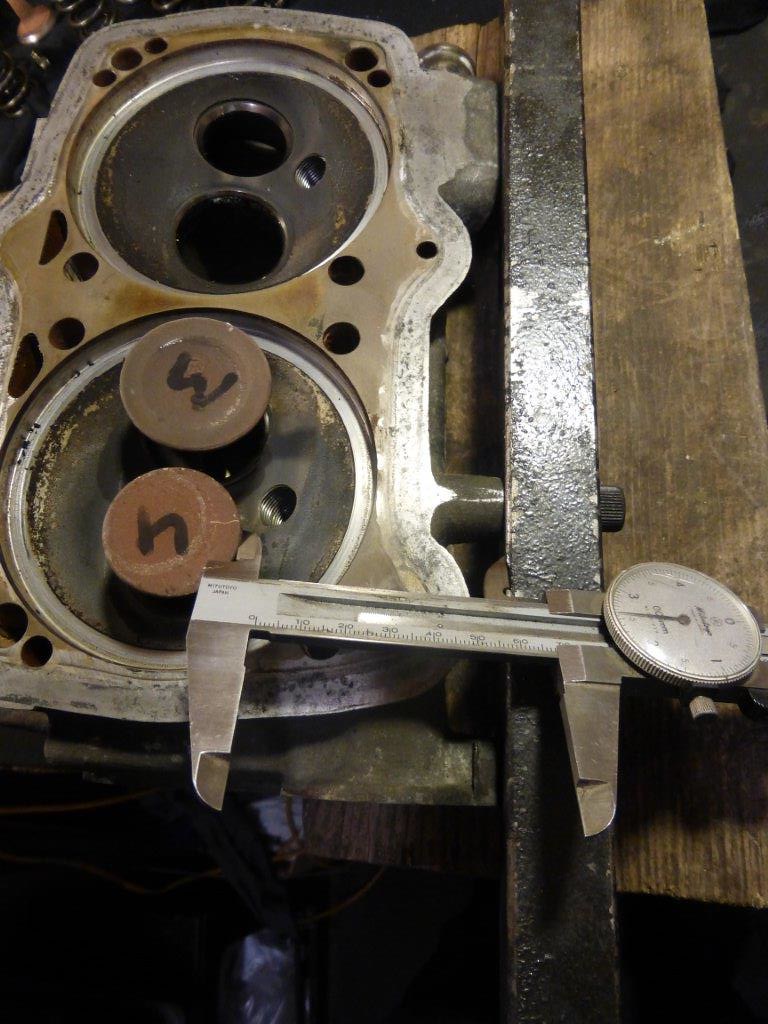

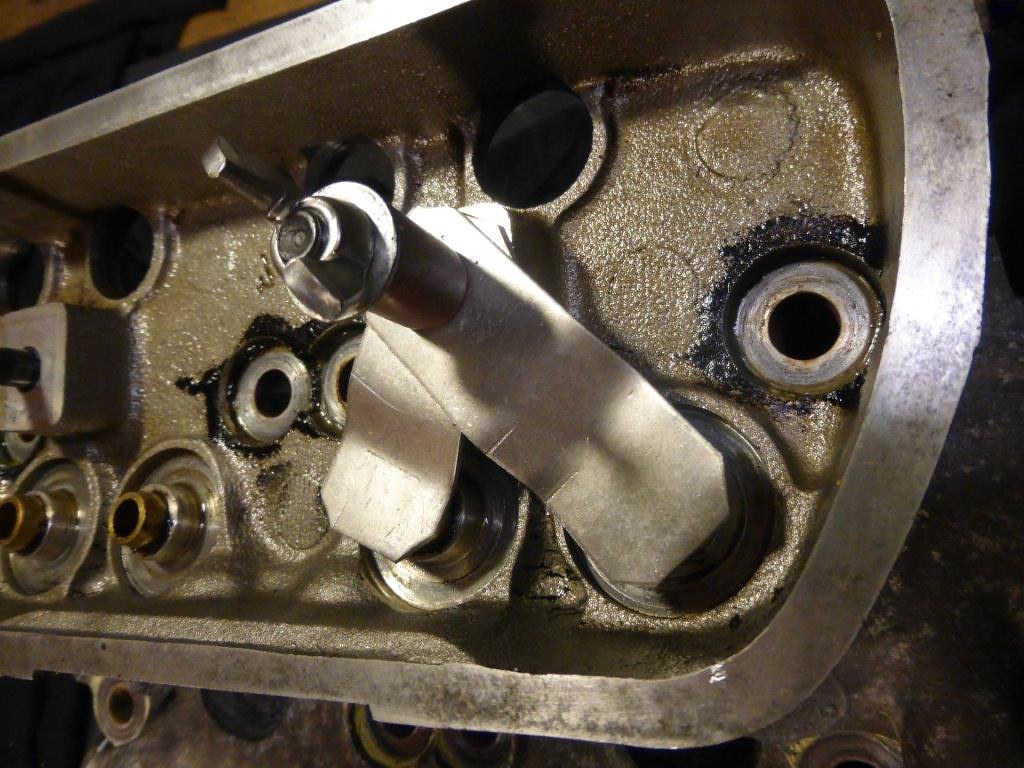

first thing I want to do is check the valve play, Bentley specifies 1.2mm with valves level with end of guides.

These brackets help the measurement

P1060323

P1060323 by

Paul_Barr, on Flickr

Turn it over and fit a square tube as a reference edge

Measured with a dial caliper

P1060324

P1060324 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 10 Nov 2016, 18:17

by itchyfeet

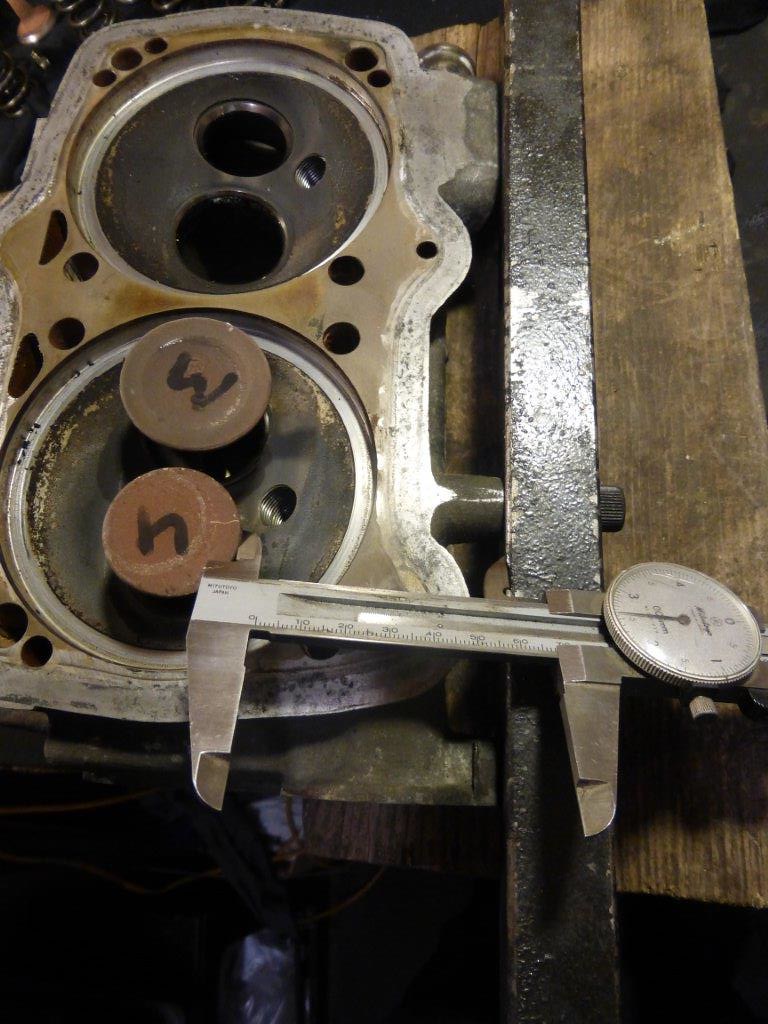

The results are disappointing, two exhaust vales are 1mm too close to wear limits for me to be happy putting these back

1&2

P1060327

P1060327 by

Paul_Barr, on Flickr

3&4

P1060328

P1060328 by

Paul_Barr, on Flickr

Spent a little time cleaning them up anyway, used an M10 threaded bar to clean out the head stud holes

P1060330

P1060330 by

Paul_Barr, on Flickr

Wires brushed the head nut surfaces and combustion chamber.

P1060331

P1060331 by

Paul_Barr, on Flickr

P1060332

P1060332 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 10 Nov 2016, 20:44

by what2do

Where you've used the threaded bar for cleaning threads, are you familiar with cutting a groove along the length of the thread with a hacksaw? Just a little tip I thought I'd mention.

Re: WBXlog

Posted: 10 Nov 2016, 20:58

by itchyfeet

Threaded bar is just like a file for cleaning the head stud clearance holes out

Re: WBXlog

Posted: 10 Nov 2016, 21:29

by what2do

itchyfeet wrote:Threaded bar is just like a file for cleaning the head stud clearance holes out

I know. The cut groove acts like a tap and prevents any binding.

Re: WBXlog

Posted: 12 Nov 2016, 17:01

by itchyfeet

I have decided to just replace the exhaust guides, the Inlet are not so bad and can stay for another day, I assume the inlets have a bit more lubrication from the fuel.

Note Inlet valves are 8mm diameter and exhaust 9mm diameter!!

I have an old head so I practised removing and refitting the guides first as I have not done this before, I had a few problems particularly with galling of the thread but that may have been low quality threaded bar.

The normal method, so I have read, is to tap the guide then using a long bolt or threaded bar and a tube spacer wind it out. Easier said than done, I found if you didn't tap right through the bolt hits the end of the thread and then starts expanding the guide which stops it moving, I snapped a bolt doing this so I moved to tapping right through not sure if it's the best way but it's what worked for me.

There are problems with tapping right through in that the tap is not long enough so I counter bored 20mm from both ends and just tapped the middle section.

Counter bore from top was 10mm followed by 11mm drill, counter bore from valve side was just 10mm

P1060362

P1060362 by

Paul_Barr, on Flickr

I used M8 studding carefully slid through the inlet valve guide acts as a good guide to drilling and tapping square, vacuum cleaner to reduce the amount of swarf left.

P1060383

P1060383 by

Paul_Barr, on Flickr

Keep pulling the drill out to check it's drilling square and evenly

P1060387

P1060387 by

Paul_Barr, on Flickr

then drill from valve side

P1060390

P1060390 by

Paul_Barr, on Flickr

using two M10 tap sizes, first runs through easy the second is a bit harder, never going to get in there with a tap wrench so used a battery drill on slow, and kept going forwards and backwards, used grease.

P1060395

P1060395 by

Paul_Barr, on Flickr

P1060396

P1060396 by

Paul_Barr, on Flickr

Checked the studding threaded through easily

P1060399

P1060399 by

Paul_Barr, on Flickr

spacer tube and washer two nuts locked off on the end, a hardened bolt would be better I think

P1060400

P1060400 by

Paul_Barr, on Flickr

wind it out

P1060401

P1060401 by

Paul_Barr, on Flickr

P1060403

P1060403 by

Paul_Barr, on Flickr

clean holes out removed as much swarf as possible with a rag first then washed it all down with paraffin

P1060404

P1060404 by

Paul_Barr, on Flickr

P1060405

P1060405 by

Paul_Barr, on Flickr

P1060406

P1060406 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 13 Nov 2016, 12:34

by itchyfeet

I got these exhaust valve guides from Brickwerks, nobody else seems to sell 9mm WBX exhaust guides?

a bit of guesswork went for the smallest oversize, they are a bit longer because they have a flange ( snigger)

I measured up and came to the conclusion I could drive them home to the flange, no other reason for it to be there I guess.

P1060342

P1060342 by

Paul_Barr, on Flickr

P1060347

P1060347 by

Paul_Barr, on Flickr

P1060354

P1060354 by

Paul_Barr, on Flickr

P1060358

P1060358 by

Paul_Barr, on Flickr

Popped the heads in the oven on the lowest gas setting, used a twin channel K type thermocouple reader to check temperatures, air temp just over 110 deg C and after 45 minutes the casting temp was about 70 deg C

P1060408

P1060408 by

Paul_Barr, on Flickr

P1060413

P1060413 by

Paul_Barr, on Flickr

guides in the freezer

P1060411

P1060411 by

Paul_Barr, on Flickr

I made this tool but I think you could use an M8 bolt with an unthreaded portion and cut the thread off.

P1060410

P1060410 by

Paul_Barr, on Flickr

out of the oven and freezer and hammered them in.

P1060415

P1060415 by

Paul_Barr, on Flickr

P1060416

P1060416 by

Paul_Barr, on Flickr

P1060417

P1060417 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 13 Nov 2016, 16:10

by itchyfeet

Oh well, if you never made a mistake you probably never made anything.

P1060419

P1060419 by

Paul_Barr, on Flickr

One was much harder to fit than the others, drilled a hole to stop the crack

P1060421

P1060421 by

Paul_Barr, on Flickr

it is quite a way from the water channel and not by the combustion chamber but I'm not happy with it.

P1060422

P1060422 by

Paul_Barr, on Flickr

was expecting to need to ream the guide but they were a good fit on valves, no reaming needed.

Cleaned the barrel compression seal and green seal mating surface with 600 grit wet and dry and paraffin ( this is a different head forgot to take this picture)

P1060163

P1060163 by

Paul_Barr, on Flickr

Ground valves with battery drill but they didn't need much, I use minimal turns and as much pull as possible, I'm aiming to replicate the speed and number of turns you would do by hand. Ran a clean piece of oiled cloth through valve guides first and oiled stems.

P1060423

P1060423 by

Paul_Barr, on Flickr

P1060424

P1060424 by

Paul_Barr, on Flickr

through clean down with carb cleaner

P1060425

P1060425 by

Paul_Barr, on Flickr

P1060429

P1060429 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 23 Nov 2016, 09:06

by george2490

Good work, needs a pic of finished article.

What was total cost?

Re: WBXlog

Posted: 23 Nov 2016, 09:29

by itchyfeet

Thanks,

It's not finished yet

I'm not happy with the head I cracked the valve guide flange, I asked Andrew at campershack to find me an uncracked head in his aladins cave of wbx parts if he can but he's a very, very busy man.

Costs are on page 2 but I changed direction half way through from a DG rebuild to a DJ I will update when finished but its a shopping list of parts because every rebuild is different in what it needs.

P1060288 by Paul_Barr, on Flickr

P1060288 by Paul_Barr, on Flickr P1060291 by Paul_Barr, on Flickr

P1060291 by Paul_Barr, on Flickr P1060292 by Paul_Barr, on Flickr

P1060292 by Paul_Barr, on Flickr P1060293 by Paul_Barr, on Flickr

P1060293 by Paul_Barr, on Flickr P1060294 by Paul_Barr, on Flickr

P1060294 by Paul_Barr, on Flickr P1060295 by Paul_Barr, on Flickr

P1060295 by Paul_Barr, on Flickr P1060296 by Paul_Barr, on Flickr

P1060296 by Paul_Barr, on Flickr P1060298 by Paul_Barr, on Flickr

P1060298 by Paul_Barr, on Flickr P1060288 by Paul_Barr, on Flickr

P1060288 by Paul_Barr, on Flickr P1060291 by Paul_Barr, on Flickr

P1060291 by Paul_Barr, on Flickr P1060292 by Paul_Barr, on Flickr

P1060292 by Paul_Barr, on Flickr P1060293 by Paul_Barr, on Flickr

P1060293 by Paul_Barr, on Flickr P1060294 by Paul_Barr, on Flickr

P1060294 by Paul_Barr, on Flickr P1060295 by Paul_Barr, on Flickr

P1060295 by Paul_Barr, on Flickr P1060296 by Paul_Barr, on Flickr

P1060296 by Paul_Barr, on Flickr P1060298 by Paul_Barr, on Flickr

P1060298 by Paul_Barr, on Flickr