the first and second run of "Andreas-springs" are ready-made and shipped some months ago, so I want to present a third round. (Some syncronauts asked for.)

I summarized the technical specifications, that I have written in the german forum.

Some more informations you will find here:

Andreas-springs: 2. round

Andreasfedern hinten: Habe sie eingebaut

Andreasfedern vorne: Projekt fertig

Andreasfedern: Erfahrungsberichte

Andreasfedern 2. Runde

I am sorry for my bad English, I hope, you will understand it!

Background:

After over 2 years I had looked after with great vigor to the Trail Master Project and had auditioned numerous times in person at the company Trailmaster, I must admit now that I have almost no hope that this will find a good result.

The already completed Trailmaster springs of the first (light) series are very suitable for light Syncros.

But my car has a daily weight of 2.5 tonnes, with traveling abroad reached quickly once a little over 3 tons.

Even with the 2.5 tonnes, the progressive (close) turns of the Trailmaster springs are constantly "on block" and thus have no more spring action. I had indeed installed temporarily, but could not be permanent.

The same problem exists in the Seikel-springs that were originally designed for a slight rally Doka.

After having driven through the Gobi desert in Mongolia with my Seikel springs thousands of kilometers of rough desert tracks in 2009, the springs had completely gone in Sibiria at Lake Baikal.

New rear Springs:

I have now in collaboration with a very experienced spring manufacturer new springs designed to match my needs.

To give the project a name, I have named it Andreas-springs.

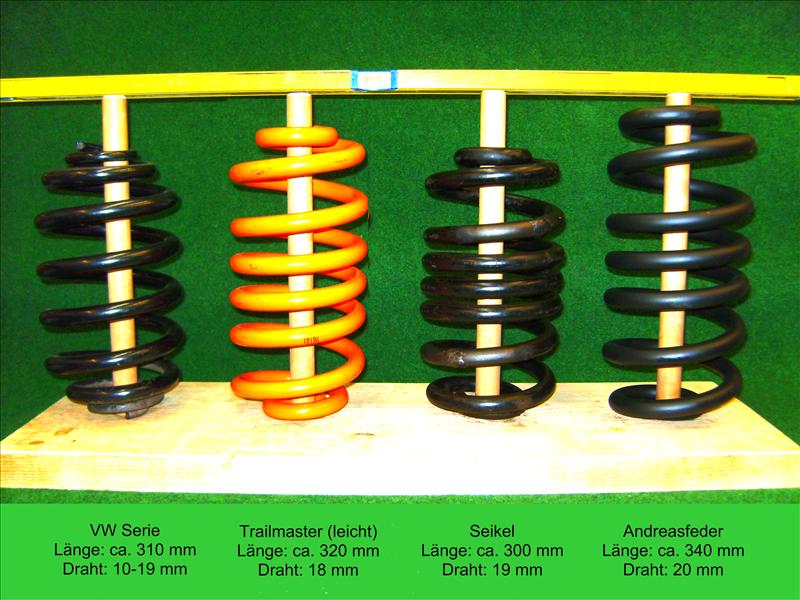

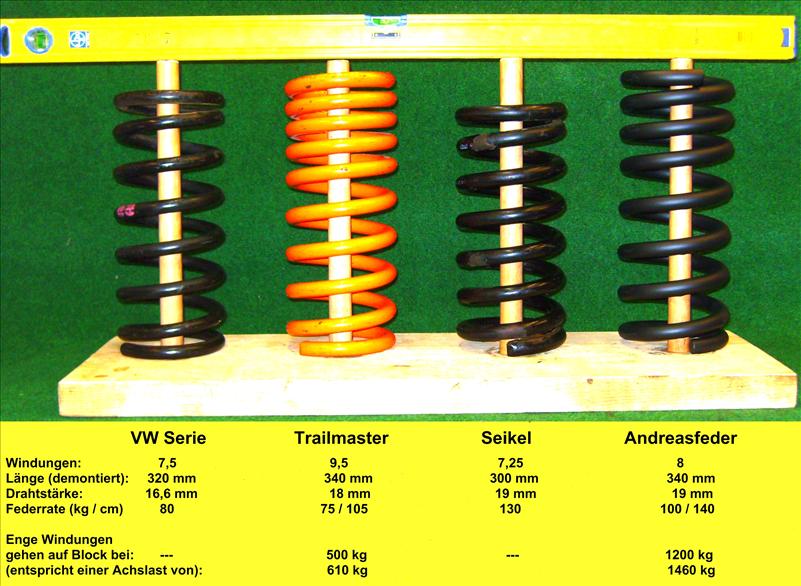

As one can easily see in the picture, Andreas spring is slightly longer, the wire is thicker and the progressive coils have more distance.

The following properties are realized with this design:

1) With a rear axle load of 1500 kg (This is my "normal state"), the car has a height of 49.5 cm (Hub center - wheel box), without spacer washers, only with the standard 10mm rubber washer. (49.5 cm at 16-inch-wheel arches; at metal-sheet wheel arches at about 50.5 cm.)

The progressive turns have a distance of 6mm.

2) In a rear-axle-load of 1850 kg (This is my "travel weight"), the car has a height of 47.5 cm (Hub center - wheel arch) (47.5 cm at 16-inch-wheel arches; at metal-sheet wheel arches at about 48.5 cm). I have determined the measure, as I have tentatively loaded in a ballast load of 500 kg. The progressive coils have then a gap of 3 mm:

This means:

Even with the high "travel weight" are still working all Coils of a spring. There is no wasted travel by rigid spacer washers or "turns on block".

This is still a reasonably useful axial twist guaranteed!

Under heavy compression, for example on a bumpy track, then put on the tight turns, and the spring is "harder".

Installation:

I used a hydraulic compressor. Without spring compressor you should disassemble the articulated shaft. Anyone who wants to avoid both: My condolences!

The production:

I could view a part of the production:

1) The wire is on a program-controlled winding machine (cold) rolled cylindrical.

2) The spring ends are drawn glowing inside.

3) The complete spring is heated to 800 degrees and hardend in oil bath

4) The spring is in the annealing furnace tempered for 1 hour at 390 degrees.

5) After cooling, the complete surface is shot blasted to the surface compaction.

6) coating the metal with special paint.

The driving experience:

Although Andreas spring is indeed a mammoth part actually, the car now seems to me a little "soft" because all turns to work and travel is longer.

Who will drop out?

All people whose car in the "normal state" significantly less than 2.5 tonnes of weight, won’t be happy with Andreas-springs.

Likewise, people who are hoping that this spring even a Rolls-Royce-driving comfort

The spring is for "Africa Through Querer".

Durability

My spring manufacturer is producing springs in limited-lot production since 40 years, from moped-springs to locomotive-springs he manufactures everything.

He knows what he's doing, and he promised me this springs are unbreakable.

Spring rate

I've charted some rear springs on a test bench. This are the spring rates I've determined: (All specifications are in kg/cm)

VW standart (2 points green): 85

The progressive effect of the thin wire ends does only affect if the load is about a few hundred kg, so it won't affect in normal states.

Trailmaster light: 80 / 105 (progressive turns on block at 750 kg)

With my rear axe load of about 1500kg the progressive turns have contact even if the car is standing.

Seikel: 80 / 120 (progressive turns on block at 450 kg)

The tight turns are permanently on block, and there are only about three turns left. They work as a linear spring with 120 kg/cm. The last turns of each end is coiled very narrow, because of this it don't work as a spring, but as a massive iron stick. But this is the situation with all the springs I've tested (except the VW standard).

Andreas-spring: 100 / 180 (progressive turns on block at 1200 kg)

Even with my "travel rear axle load" of about 1800 kg, the thight turns are slightly open, and the car is reasonably soft with a spring rate of 100kg/cm. All turns (but the end-turns) are working as a spring and the car has a suitable axial twist.

But it seems to me, that the car has a higher tendency to roll.

If the spring get compressed a little bit more (because of a pot-hole or a bumpy track), the progressive turns get in contact, so the springs become very strong and the car has still a usable clearance hight. Anyway the car has still a working spring system.

The other springs I tested will likely snap through, so they have no resilience left and the auto-body will be shacked to the core.

The Andreas springs preserve the auto-body in some way, because the car drives on soft springs with 100 kg/cm and a big spring range most of the time, and not on (heavy- Seikel-) 120 kg/cm with a quite small spring range.

However, affected by the win of clearance hight, the load of the articulated shafts is higher.

Andreas-springs with Trailmaster-(sport)-shock-absorbers rear

I did serveral test runs with new rear Trailmaster shock absobers. (So far I only used old standard shock absorbers (Boge)).

The TM's are working fine. I should have changed before. The higher tendency to roll I talked about is not a problem anymore.

Test runs:

To check the stability under load of the Andreas springs, I drove several rough laps on a frozen acre with the overweight of 3,2 tons!

As extra ballast I loaded 500 kg.

After the first few laps, I unloaded the car and could measure that the new spring subsided about 5 mm. This is a normal process in new springs.

After that I reloaded the car, and even after lots of more laps, there was no more subsiding,

The high-measurements at the beginning of this description are the data after the subsiding.

Therewith the rear-springs are ready-made.

New front-springs

Directly after the rear-spring-project, I started to develop new front springs.

Prototype without coating:

After a couple of prototypes, I installed the first "finished" batch of front-springs and did a test-run.

The length of the spring (high of the car) is correct, and the progressive (tight) turns are perfect.

The driving experience:

On street:

They feel comfortable (soft), because all turns are working.

On a frozen acre with adamant mole-hills:

The Springs start to cushion really soft, but when I drove through grooves or over bumps the progression starts to affect, the spring becomes harder and doesn't snap through.

spring rate:

I charted 4 different springs on a Test bench (all data in kg/cm)

VW standard: 80

Trailmaster: 75 / 105

Seikel: 130

Andreas-spring: 100 / 140

With a front axle load of 1100 kg (that's the normal state of my syncro) the car has a high of 49,5 cm (hub center - wheel box)

[49.5 cm at 16-inch-wheel arches; at metal-sheet wheel arches at about 50.5 cm]

with one 6 mm Trailmaster spacer-washer installed.

(I installed this, to prevent the articulated shaft to get in contact with the spring seat.)

The progressive turns have a gap of 6 mm.

With extra ballast of 200 kg, I have an axle load of 1300 kg, in this situation the progressive turns have a gap of 3 mm.

Lever arms at the lower traverse control arm:

At the front axle, the situation is, that the spring (+ shock absorber) is working on a lever-arm of about 61%, if you define the center of the tire-footprint as 100% lever arm.

The percentage quotation also depend a little bit on the wheel offset and if you have track extension plates installed or not. Also the small inclination of the shock absorber has in theory an influence on the percentage quotation. But this doesn't have much effect, so you can forget about that in this situation.

That means,

that with a front axle load of 1100 kg (tire-load 550 kg) each spring is loaded with about 900kg. (550kg : 61%)

Upper traverse control arm ("horseshoe"):

As you can see on the picture above, I installed the narrow turns lower and the wide turns upper.

After several tests with the Trailmaster spring seats (rotatable) I found a setup that makes a complete rebounding possible, without the upper traverse control arm touching the spring. (An instruction how to install the spring in this position is part of each shipment.)

Of course, you can install the Andreas-springs with all other shock absorbers!

Driving impression:

As I told above for the rear Andreas-spring, the car drives "softer" compared with the Seikel-springs, not until you cross heavy bumps or grooves the narrow turns get on block and the higher spring-rate prevents the car to subside to much.

Just to remind you: The Andreas-springs are only suitable for heavy-weight Syncros, light cars will be lifted too high!

Some pictures of my syncro, equipped with Andreas springs, and a weight of 2,6 tons.

(Size of tire: 31 x 10,5 / 15", this is approximate 265 / 70 x 16")

Hier ein Bild der möglichen Verschränkung:

A picture of the possible axial twist:

Der Bierkasten hat normalerweise eine Höhe von 30 cm, unter dem Gewicht hat er aber leicht nachgegeben.

Es sind also ca. 27 cm.

The beer box normaly has a height of 30 cm, but under the weight he gave way a little bit.

Really it is about 27 cm.

Die anderen 3 Räder stehen noch auf dem Boden.

The outher 3 wheels are standing on the ground.

Die Andreasfedern haben "auf ganzer Länge" Federwirkung! Es ist also kein Federweg verschenkt durch starre Höherlegungsscheiben.

The Andreas Springs are elastical on the complete length. No spring travel is lost by spacers.

Interested?

The price for one couple (2 pieces) of rear springs is: 260,-€

The price for one couple (2 pieces) of front springs is: 240,-€

Additionally the shipping costs:

To Germany: 7,-€ for each couple

To other EU-countries: 19€ for each couple

This is the mode of order:

Order-time limit: 1. January 2012

1) Du: Eine E-Mail an andreaslidl@web.de mit der Lieferadresse und der gewünschten Menge.

You: Email to andreaslidl@web.de, with delivery-adresse and the wanted quantity

2) Ich: Per E-Mail sende ich meine Kontodaten

I: Email with the account-number

3) Du: Geld überweisen

You: Transfer the money

4) Ich: Versand nach Ende der Bestellfrist. Lieferzeit dann: ca. 4 Wochen (Die werden ja dann erst angefertigt.)

I: Delivery after the end of order-time-limit: about 4 weeks later

I'm not a professional dealer or another type of commercial supplier, but this is a private sale.

The springs don't have what we call in Germany “ABE” (this is a document that makes it possible to use the springs in public traffic legally), or any other accompanying documents.

Greetings Andreas