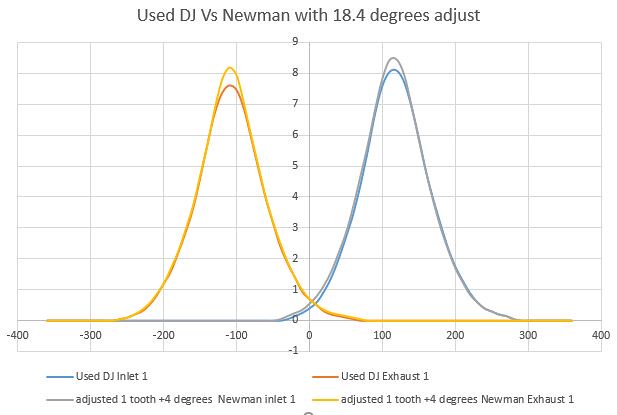

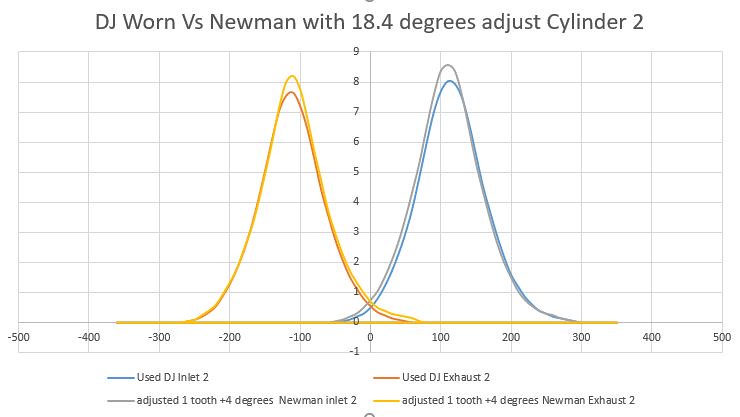

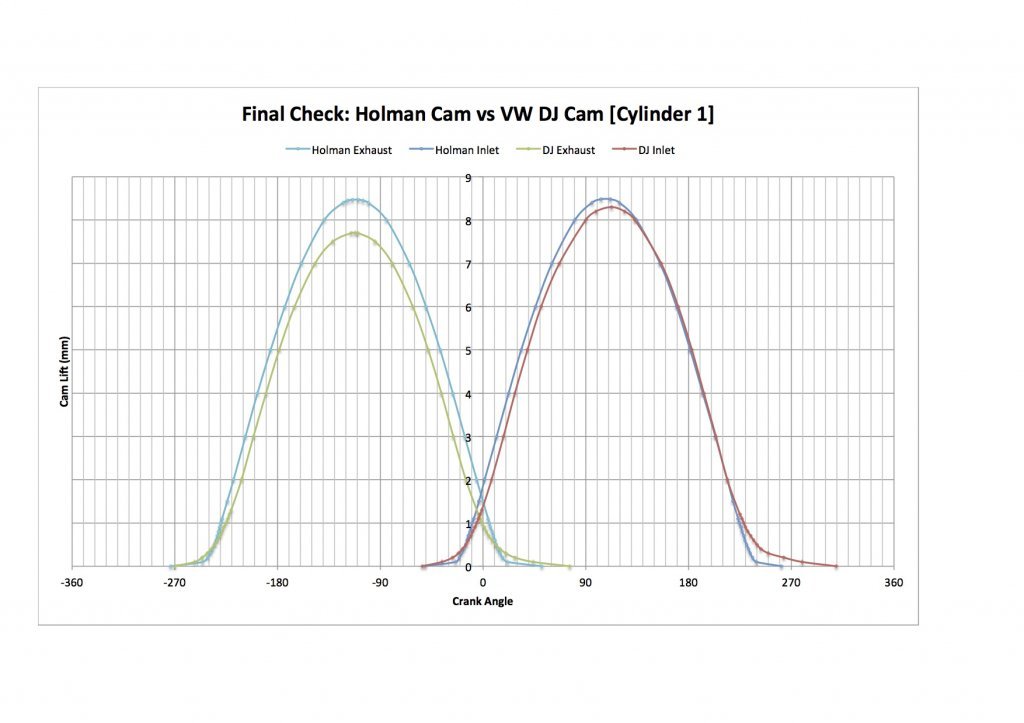

FRom this data it looks like the adjustement might need to be around 18 degrees, but as you've done the spreadsheet now you can just mess with it until you get the best fit. Desktop engineering

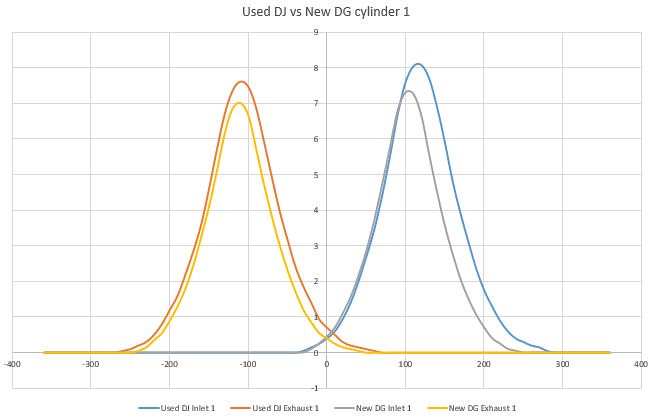

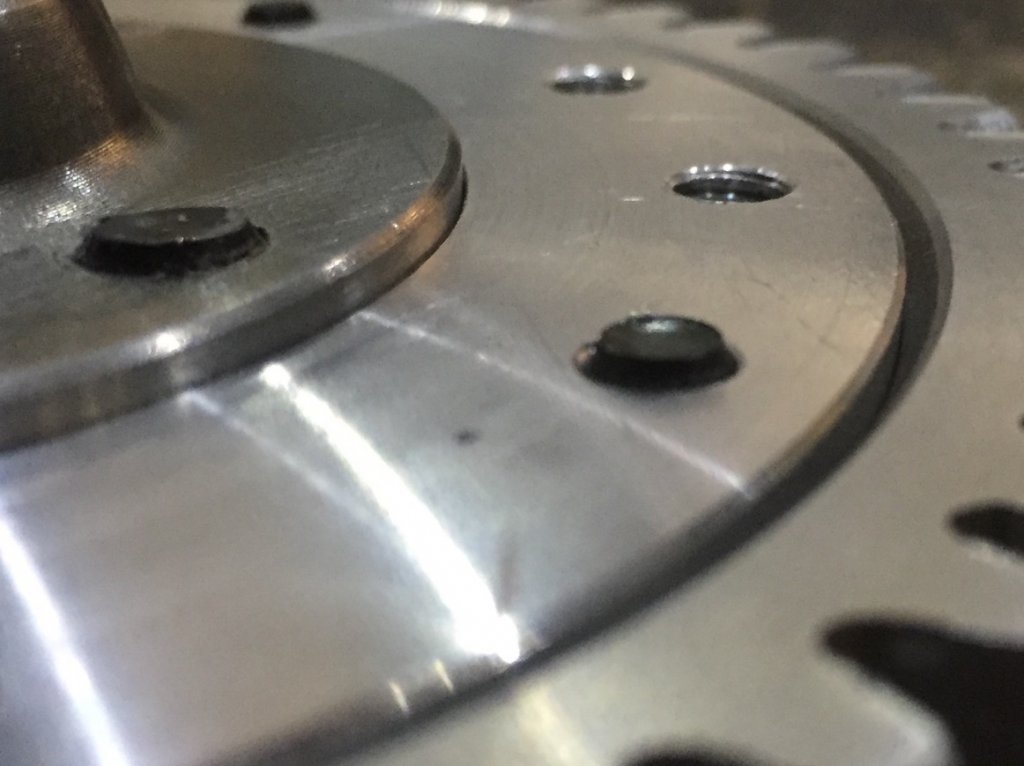

I think you've done a great job setting up the tool to measure the cams. The more you take measurements, the easier I suppose it will come, but I know there'll be a lot of work in taking those 250 measurements eachtime. Now you have the profile, maybe just focus on the peak of each lobe for the alignment... and perhaps not assume that each lobe is exactly 90 degrees round from the previous cylinder in firing order