I've also come to a full stop as all advice is not to work around a vapour filled fuel tank and removal seems like an over complex job with all various pipes, coupled to which I have snapped 1 screw and can't move a 2nd on the filler cap. Everything currently soaking in WD 40.

I was told yesterday by my neighbour that a good friend of his blew himself up welding near a fuel tank so enough said but as the following pictures might indicate I could not resist some cutting but that has all now stopped.

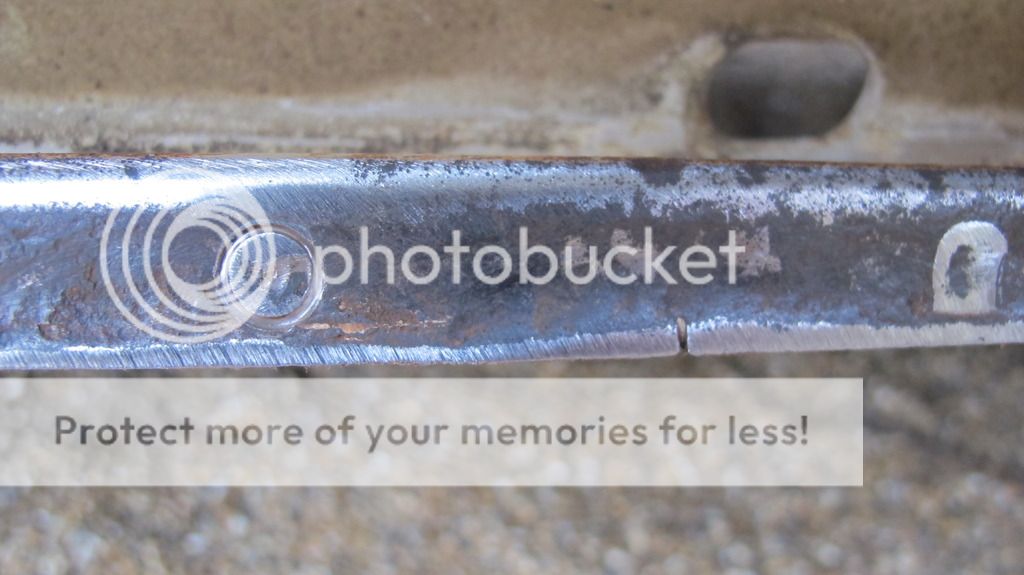

The posts (I think they might be B & C) don't seem too bad although the rear vertical seam on the panel is not brilliant but I will just treat this time round. Two other ponderables is whether I should weld in a strip along the bottom inner sill as the metal is quite pitted with rust - as a newbie welder I would rather avoid but suspect the outer sill wont stick.

The second debate is how far I should cut in on the closures (MM

Turning to the front section - seams are good - yet to remove last bit of outer sill - and inside is filled with thick paint - again question how far I should cut in.